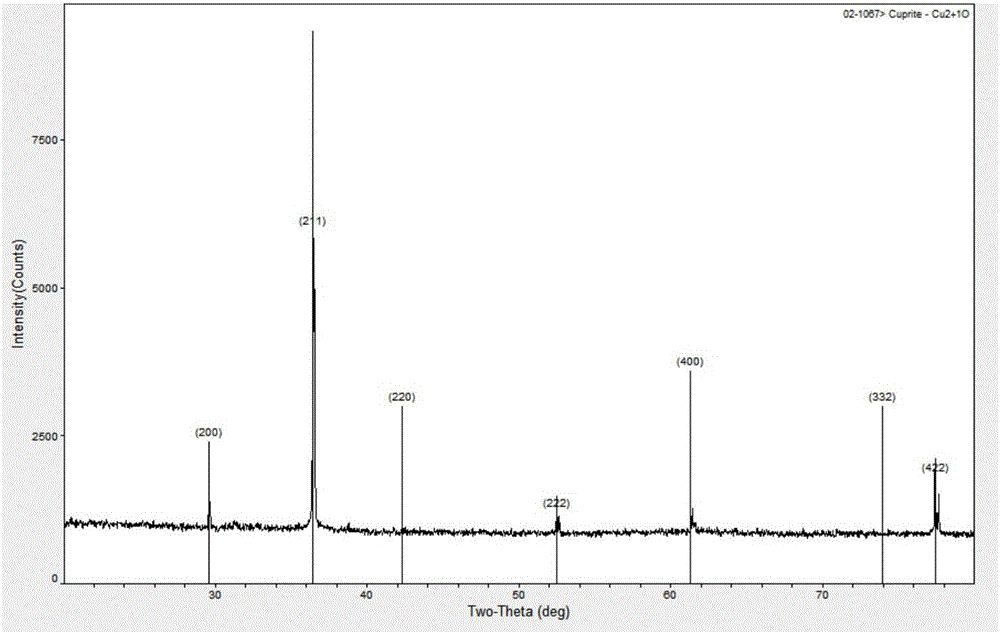

Preparation method of high quality p-type cuprous oxide film

A cuprous oxide, high-quality technology, applied in copper oxide/copper hydroxide and other directions, can solve the problems of unfavorable large-scale industrial production, uneven film thickness distribution, low film density, etc., and achieves abundant storage capacity and simple method. Feasible, large grain size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1) Cut a copper sheet with a purity of 99.999% and a thickness of 0.01mm to a size of 20mm×20mm, prepare a nitric acid solution with a mass fraction of 20%, and clean the copper sheet with tweezers in nitric acid for 30 seconds, then use deionized water Rinse well and blow dry with nitrogen gas for later use.

[0015] 2) Put the cleaned copper piece in the quartz boat and put it into the tube furnace, first use the mechanical pump to pump out the air, then pass in the argon, repeat several times until the air is completely removed, turn off the mechanical pump, and keep the argon in . Raise the temperature to 1050°C at a rate of 15°C / min, and keep it warm for one hour.

[0016] 3) At a temperature of 1050°C, stop feeding argon, start feeding air into one end of the tube furnace, and use a mechanical pump to pump air at the other end to make the air flow unimpeded, and keep warm for one hour.

[0017] 4) At a temperature of 1050° C., repeat the steps in step 2), and ke...

Embodiment 2

[0021] 1) Cut a copper sheet with a purity of 99.999% and a thickness of 0.2mm to a size of 10mm×10mm, prepare a nitric acid solution with a mass fraction of 20%, and clean the copper sheet in nitric acid for 30 seconds with tweezers, and then use deionized water Rinse well and blow dry with nitrogen gas for later use.

[0022] 2) Put the cleaned copper sheet in the quartz boat and put it into the tube furnace, first use the mechanical pump to pump out the air, then pass in the argon, repeat several times until the air is completely removed, turn off the mechanical pump, and keep the argon in . Raise the temperature to 1100°C at a rate of 15°C / min, and keep it warm for one hour.

[0023] 3) At a temperature of 1100°C, stop feeding argon, start feeding air into one end of the tube furnace, and use a mechanical pump to pump air at the other end to make the air flow unimpeded, and keep warm for one hour.

[0024] 4) At a temperature of 1100° C., repeat the steps in step 2), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com