Fermentation complete mixing feed for livestock and production method of fermentation complete mixing feed

A total mixing and feed technology, applied in animal feed, animal feed, animal husbandry, etc., can solve the problems of low nutritional value, inconvenient feeding, single ingredients, etc., and achieve the effect of rich nutrition, good palatability, and easy digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

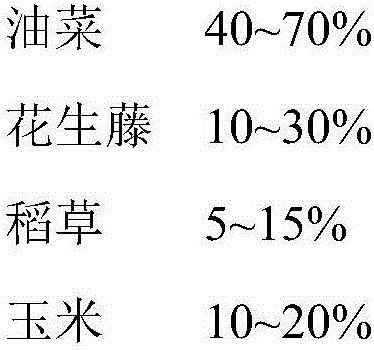

[0018] The formula of the feed is as follows:

[0019]

[0020] Rapeseed is low in erucic acid and low in glucosinolates, with a protein content of about 12.2%, and a digestible energy of 12.4MJ / kg;

[0021] Corn is commercially available corn with a protein content of 8.7% and a digestible energy of 14.3MJ / kg;

[0022] The protein content of peanut vine is about 11%, and the digestible energy is 9.5MJ / kg;

[0023] The protein content of rice straw is 2.5%, and the digestible energy is 6.8MJ / kg;

[0024] Each kilogram of premix contains 7g of copper, 30g of iron, 35g of zinc, 30g of manganese, 100mg of iodine, 100mg of cobalt, 100mg of selenium, and the rest are auxiliary materials.

[0025] The preparation method of the feed is as follows: cut rapeseed, peanut vines, and straw into 2-5 cm long sections, add corn and premix, stir well, then add activated yeast accounting for 0.86% of the total weight of the material, stir and mix evenly, press Fermented for 3 weeks after...

Embodiment 2

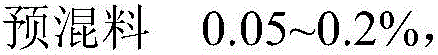

[0028] The formula of the feed is as follows:

[0029]

[0030] In every kilogram of premix, it contains 11.5g of copper, 31.7g of iron, 55.2g of zinc, 43.6g of manganese, 110mg of iodine, 125mg of cobalt and 115mg of selenium.

[0031] The preparation method of the feed is as follows: cut rapeseed, peanut vines and straw into 2-5cm long sections, add corn and premix, stir well, then add activated yeast accounting for 0.5% of the total weight of the materials, stir and mix evenly, press Fermented for 3 weeks after sealing.

Embodiment 3

[0033] The formula of the feed is as follows:

[0034]

[0035] The preparation method of the feed is as follows: cut rapeseed, peanut vines and straw into 2-5cm long sections, add corn and premix, stir well, then add activated yeast accounting for 1% of the total weight of the materials, stir and mix evenly, press Fermented for 3 weeks after sealing.

[0036] The feeding effect of embodiment 1~3 is as shown in table 1:

[0037] Table 1 Feeding average daily gain, average daily feed intake and disease incidence

[0038]

[0039] Note: This feeding experiment was carried out in Hubei Zhiqinghe Agriculture and Animal Husbandry Co., Ltd. 120 Hu sheep were selected and divided into four groups with the same ratio of male and female for fattening experiment. The weight of each group was the average value of the group. Results After multiple comparisons, the weight gain of each experimental group was significantly higher than that of the control group (P<0.01), and the incid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com