Preparation method for nano-sized zirconium-based cation metal organic framework (Zr-MOFs) materials carrying anionic medicine

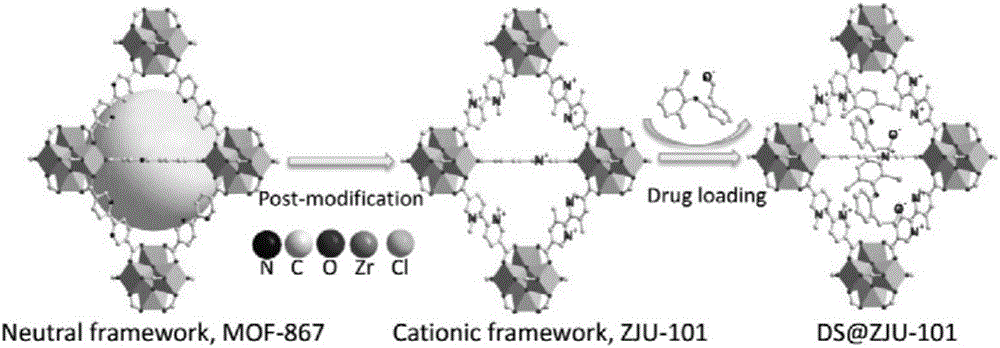

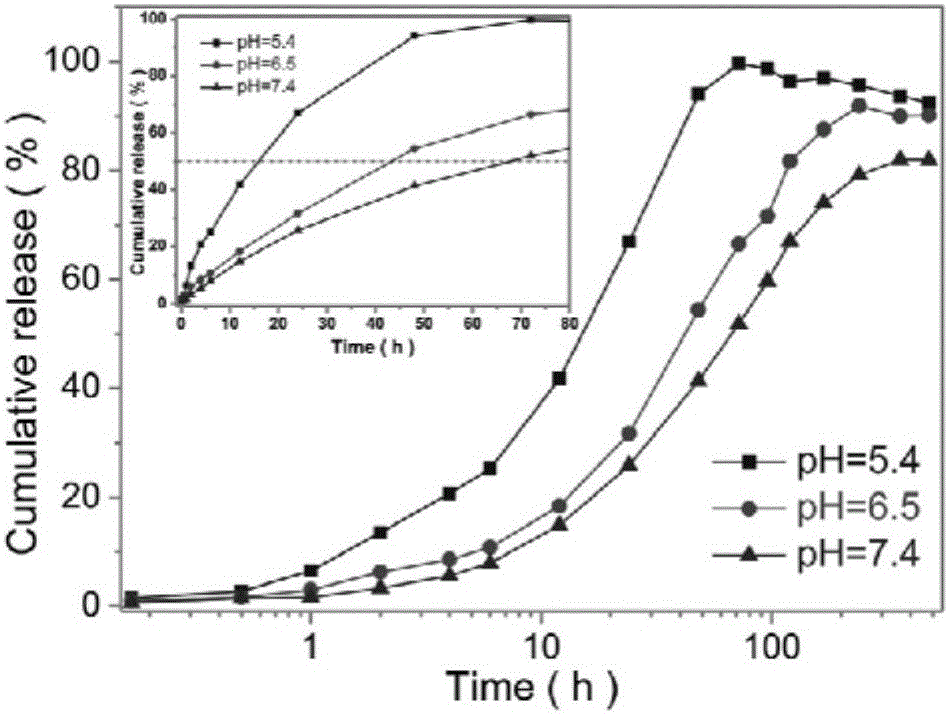

A metal-organic framework and anionic technology, applied in medical preparations with non-active ingredients, medical preparations containing active ingredients, drug combinations, etc., can solve the problem of small loading, micron-level size, uncontrolled release, etc. Problems, to achieve the effect of large drug loading and increase loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) ZrCl is mixed with a reactor 4 (11.7mg, 0.05mmol) and N-containing organic ligand pyridine-2,5-dicarboxylic acid (8.35mg, 0.05mmol) were uniformly dissolved in N,N-dimethylformamide (DMF, 18mL), and then added A small amount of glacial acetic acid (2mL, 35mmol), ultrasonically oscillated for 10min, and placed in an oven at 120°C for 24h;

[0031] (2) Centrifuge after cooling at room temperature, disperse the precipitate in DMF (10mL), repeat centrifugal washing 3 times, after centrifugation, disperse the sample evenly in acetone (10mL), let stand for 24h, add acetone (10mL) again after centrifugation ), repeating for three days, the obtained precipitate is a Zr-MOFs material that has not been cationized;

[0032] (3) Take the Zr-MOFs material synthesized above and dry it in a vacuum oven at 60°C for 12 hours;

[0033] (4) Use a glass bottle to disperse the dried Zr-MOFs material (700mg) in CHCl 3 (15mL), then added dropwise methyl trifluoromethanesulfonate (4.44m...

Embodiment 2

[0040] (1) ZrCl is mixed with a reactor 4 (11.7mg, 0.05mmol) and N-containing organic ligand 2,2'-bipyridine-5,5'-dicarboxylic acid (24.4mg, 0.1mmol) were uniformly dissolved in N,N-dimethylformamide (DMF , 18mL), a small amount of glacial acetic acid (2.29mL, 40mmol) was added, ultrasonically oscillated for 10min, and placed in an oven at 120°C for 24h;

[0041] (2) Centrifuge after cooling at room temperature, disperse the precipitate in DMF (10mL), repeat centrifugal washing 3 times, after centrifugation, disperse the sample evenly in acetone (10mL), let stand for 24h, add acetone (10mL) again after centrifugation ), repeating for three days, the obtained precipitate is a Zr-MOFs material that has not been cationized;

[0042] (3) Take the Zr-MOFs material synthesized above and dry it in a vacuum oven at 60°C for 12 hours;

[0043] (4) Use a glass bottle to disperse the dried Zr-MOFs material (700mg) in CHCl 3 (15mL), then added dropwise methyl trifluoromethanesulfonate ...

Embodiment 3

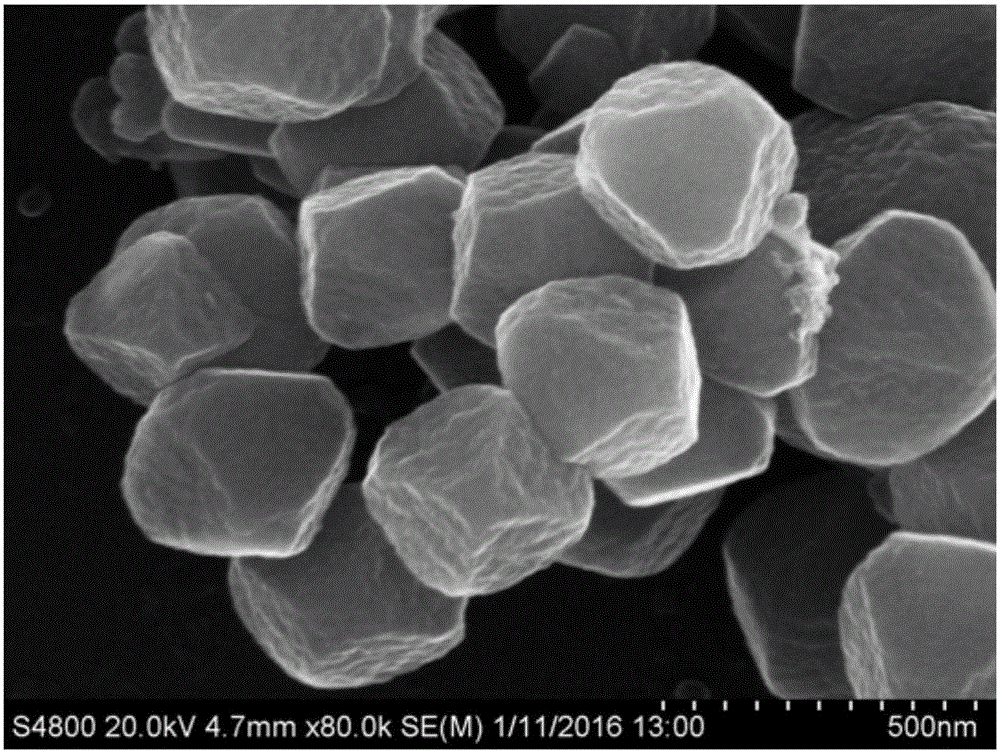

[0048] (1) ZrCl is mixed with a reactor 4 (11.7mg, 0.05mmol) and N-containing organic ligand 4,4'-(pyridine-2,5-ylidene)benzoic acid (44.3mg, 0.15mmol) were uniformly dissolved in N,N-dimethylformamide ( DMF, 18mL), then add a small amount of glacial acetic acid (2.86mL, 50mmol), ultrasonically oscillate for 10min, and put it in an oven at 120°C for 24h;

[0049] (2) Centrifuge after cooling at room temperature, disperse the precipitate in DMF (10mL), repeat centrifugal washing 5 times, after centrifugation, disperse the sample evenly in acetone (10mL), let stand for 24h, add acetone (10mL) again after centrifugation ), repeated for three days, and the obtained precipitate was a Zr-MOFs material that had not been cationized;

[0050] (3) Take the Zr-MOFs material synthesized above and dry it in a vacuum oven at 60°C for 12 hours;

[0051] (4) Use a glass bottle to disperse the dried Zr-MOFs material (700mg) in CHCl 3 (15mL), then added dropwise methyl trifluoromethanesulfon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com