Method for recycling tellurium from tellurium anode slime

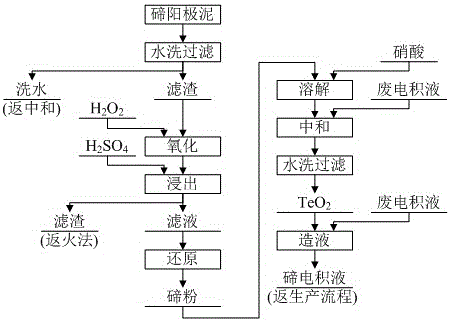

A technology of anode slime and tellurium powder, applied in the direction of element selenium/tellurium, electrolysis process, electrolysis components, etc., can solve the problems of low conversion rate of tetravalent tellurium, harsh working conditions, introduction of impurity iron, etc., and achieve easy operation, implementation and production High practicability and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 120kg of anode slime produced by tellurium electrowinning and place it in a stainless steel reaction kettle, wash it with distilled water 3 times, filter and separate, store the filtrate for later use, add 10L hydrogen peroxide to the filter residue and oxidize it for 2 hours. Analysis of its composition is: Te42.2%, Pb0.004%, Cu0.002%, Si0.1%, Se0.07%, Bi0.002%. Start the stirring and raise the temperature to about 70°C, slowly and evenly add dilute sulfuric acid to the tellurium anode slime, leaching for 3 hours, and control the pH value of the leaching end point to 1.5. Heat the filtrate to 80~85°C and reduce to Te 6+ 1.25 times of theoretical consumption added Na 2 SO 3 Solid, stirred and reacted for 6h and filtered to obtain tellurium powder.

[0022] Then put the coarse tellurium powder in a stainless steel reaction kettle, and slowly add 25% nitric acid by mass fraction to dissolve the tellurium powder. , and then pump anode slime washing water and tellu...

Embodiment 2

[0024] Take 150kg of anode slime produced by tellurium electrowinning and put it in a stainless steel reaction kettle, wash it with distilled water 3 times, filter and separate, store the filtrate for later use, add 15L hydrogen peroxide to the filter residue and oxidize it for 2 hours. Analysis of its composition is: Te44.6%, Pb0.003%, Cu0.001%, Si0.2%, Se0.08%, Bi0.001%. Turn on the stirring and raise the temperature to about 70°C, slowly and evenly add dilute sulfuric acid to the tellurium anode slime, leaching for 3 hours, and control the pH value of the leaching end point to 1. Heat the filtrate to 80~85°C and reduce to Te 6+ 1.4 times of theoretical consumption added Na 2 SO 3 Solid, stirred and reacted for 6h and filtered to obtain tellurium powder.

[0025] Then put the coarse tellurium powder in a stainless steel reaction kettle, and slowly add 28% nitric acid to dissolve the tellurium powder. The reaction is an exothermic reaction. The gas generated is absorbed by...

Embodiment 3

[0027] Take 130kg of anode slime produced by tellurium electrowinning and place it in a stainless steel reaction kettle, wash it with distilled water 3 times, filter and separate, store the filtrate for later use, add 15L hydrogen peroxide to the filter residue and oxidize it for 2 hours. Analysis of its composition is: Te40.5%, Pb0.002%, Cu0.001%, Si0.16%, Se0.06%, Bi0.001%. Turn on the stirring and raise the temperature to about 70°C, slowly and evenly add dilute sulfuric acid to the tellurium anode slime, leaching for 3 hours, and control the pH value of the leaching end point to 1. Heat the filtrate to 80~85°C and reduce to Te 6+ Add Na to 1.5 times of theoretical consumption 2 SO 3 Solid, stirred and reacted for 6h and filtered to obtain tellurium powder.

[0028] Then put the coarse tellurium powder in a stainless steel reaction kettle, and slowly add 20% nitric acid by mass fraction to dissolve the tellurium powder. , and then pump the anode slime washing water and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com