A printing and dyeing wastewater treatment agent based on cassava residue

A technology for printing and dyeing wastewater and cassava residue, which is applied in textile industry wastewater treatment, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve problems such as unfavorable growth of aquatic organisms, serious chromaticity of printing and dyeing wastewater, affecting sunlight transmission, etc. Achieving good effect, good effluent quality and good precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

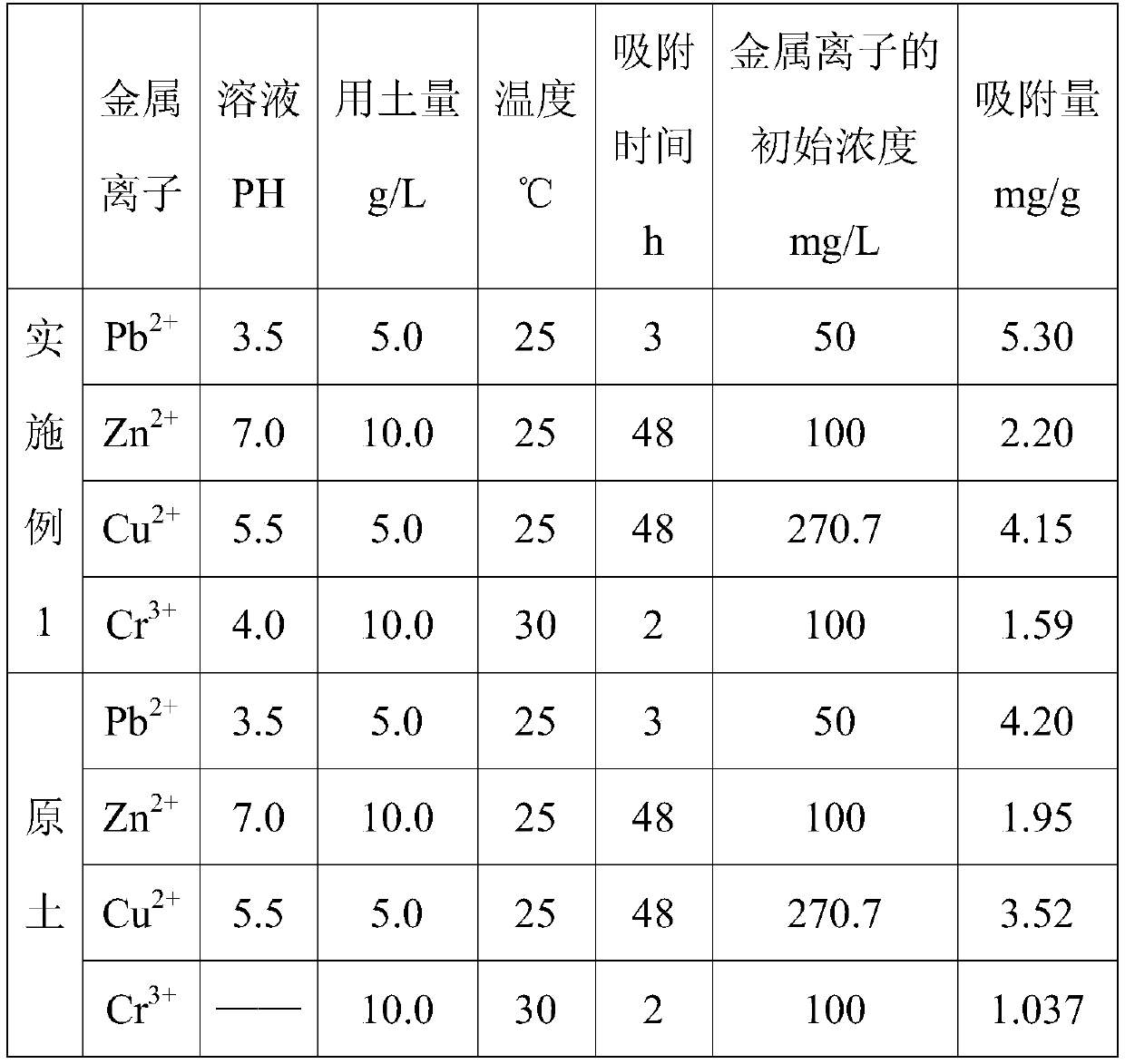

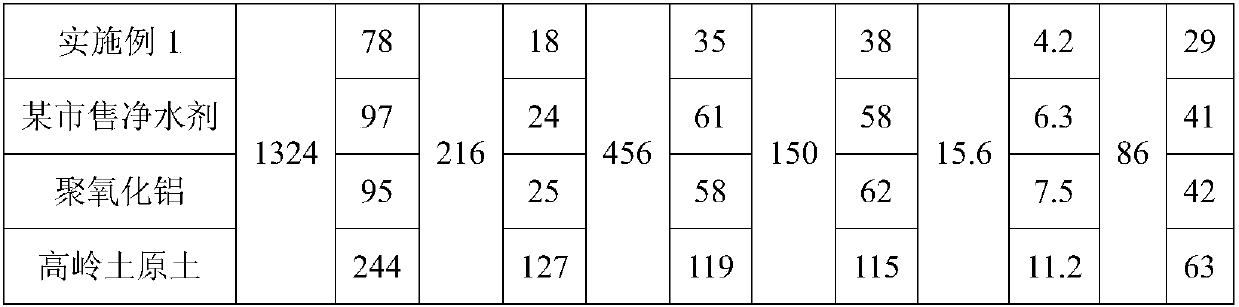

Examples

Embodiment 1

[0017] A printing and dyeing wastewater treatment agent based on cassava residues, in parts by weight, comprising the following components:

[0018] 100 parts of cassava slag, 25 parts of activated carbon, 40 parts of white boronite ethyl oxalate modified kaolin, 25 parts of lime, 3 parts of barium sulfate, 12 parts of silica gel, 25 parts of polyaluminum oxide, 12 parts of calcium sulfite, sodium polyacrylate 8 parts, 3 parts of sucrose 2-acrylate.

[0019] The preparation method of the described white boronite ethyl oxalate composite modified kaolin comprises the following steps:

[0020] (1) Ingredients: take by weighing 160g of leucumite, 500g of ethyl oxalate, and 900g of kaolin respectively;

[0021] (2) Mixing: mix kaolin and vitreousite evenly, then add ethyl oxalate and stir evenly;

[0022] (3) Reaction: Pour the mixture into a high-temperature and high-pressure reactor, fill the reactor with inert gas and exhaust the air, adjust the pressure in the reactor to 2.2M...

Embodiment 2

[0038] A printing and dyeing wastewater treatment agent based on cassava residues, in parts by weight, comprising the following components:

[0039] 80 parts of cassava residue, 20 parts of activated carbon, 30 parts of kaolin, 20 parts of lime, 1 part of barium carbonate, 10 parts of silica gel, 20 parts of polyalumina, 10 parts of calcium sulfite, 5 parts of sodium polyacrylate, 1 part of sucrose 2-acrylate share.

[0040] The kaolin is a composite modified kaolin of white boronite ethyl oxalate, and its preparation method comprises the following steps:

[0041] (1) Batching: the ratio by weight is boronite: ethyl oxalate: kaolin=5:20:40 and take each component for subsequent use;

[0042] (2) Mixing: mix kaolin and vitreousite evenly, then add ethyl oxalate and stir evenly;

[0043] (3) Reaction: Pour the mixed material into a high-temperature and high-pressure reactor, fill the reactor with inert gas to exhaust the air, adjust the pressure in the reactor to 2Mpa, and the...

Embodiment 3

[0046] A printing and dyeing wastewater treatment agent based on cassava residues, in parts by weight, comprising the following components:

[0047] 120 parts of cassava slag, 30 parts of activated carbon, 50 parts of white boronite ethyl oxalate modified kaolin, 30 parts of lime, 5 parts of barium salt, 15 parts of silica gel, 30 parts of polyaluminum oxide, 15 parts of calcium sulfite, sodium polyacrylate 10 parts, 5 parts of sucrose 2-acrylate.

[0048] The barium salt is one or more combinations of barium carbonate, barium chloride or barium sulfate.

[0049] The kaolin is a composite modified kaolin of white boronite ethyl oxalate, and its preparation method comprises the following steps:

[0050] (1) Batching: the ratio by weight is leucumite: ethyl oxalate: kaolin=10:30:50 and take each component for subsequent use;

[0051] (2) Mixing: mix kaolin and vitreousite evenly, then add ethyl oxalate and stir evenly;

[0052] (3) Reaction: Pour the mixed material into a hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com