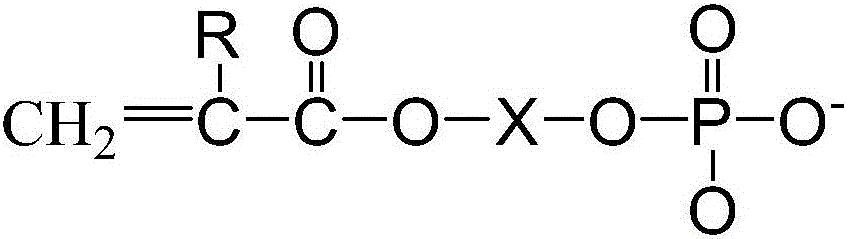

Concrete viscosity reducer and preparation method thereof

A technology of concrete and viscosity reducer, which is applied in the field of chemical building materials, can solve the problems of difficult cost of large monomer raw materials, complex preparation process of admixtures, complex purification process, etc., to achieve easy mass production, improve pumping construction performance, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

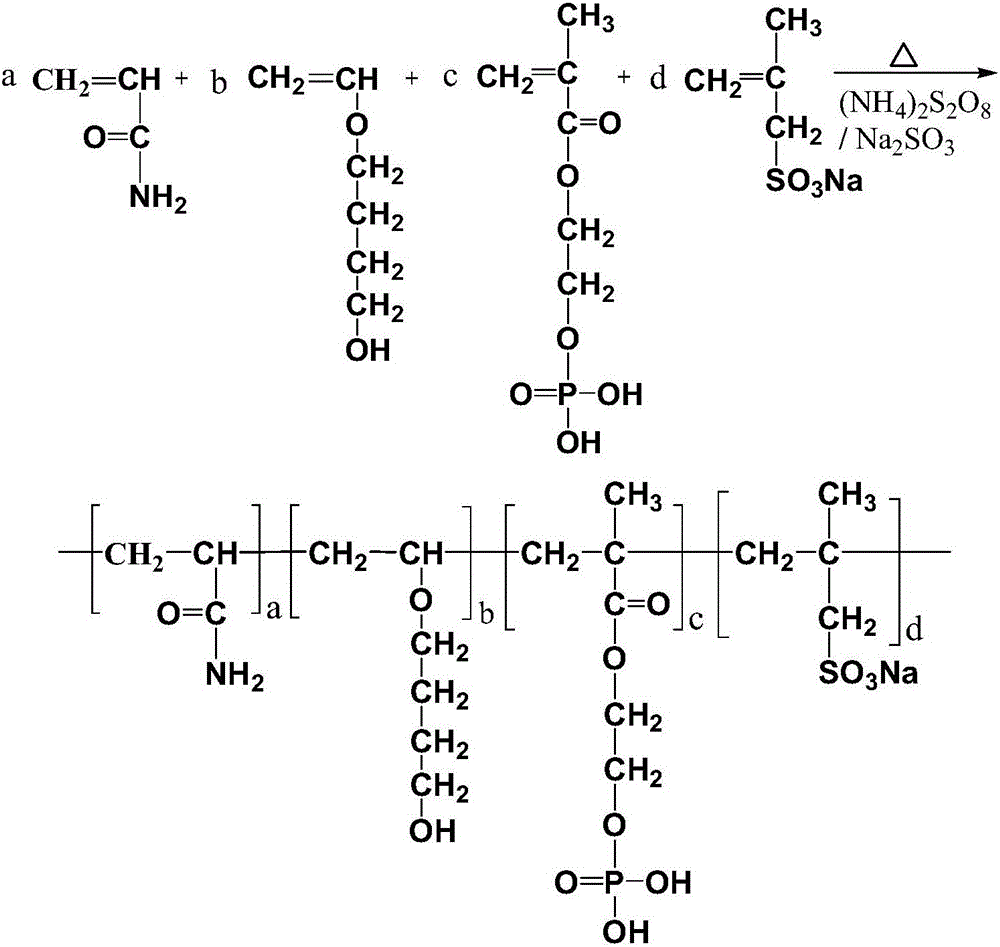

Method used

Image

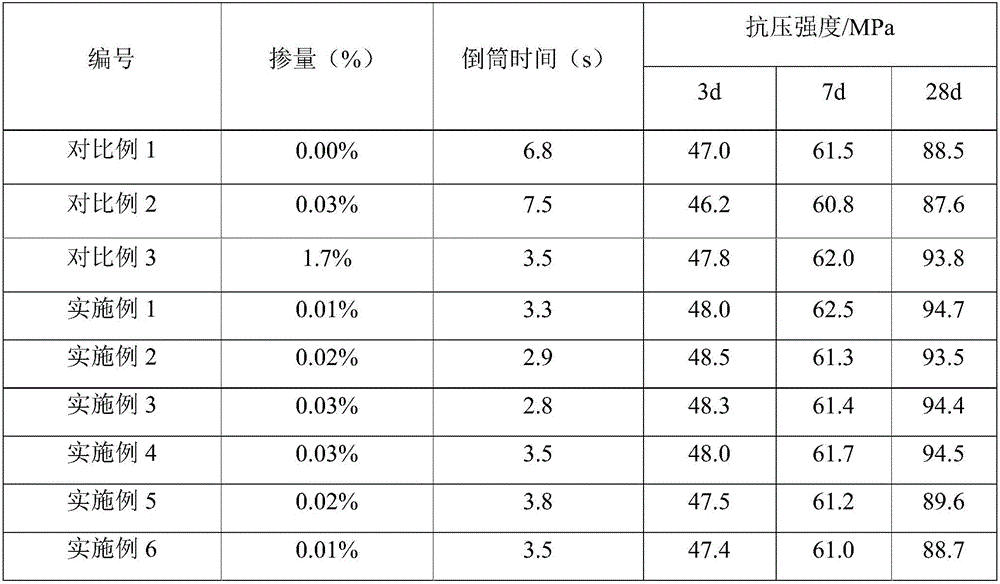

Examples

Embodiment 1

[0032] A concrete viscosity reducer, the monomers involved are 4-hydroxybutyl vinyl ether, acrylamide and methacrylic acid-β-hydroxyethyl phosphate, and its material ratio is 1:0.5:0.01. Its preparation The method includes the following steps:

[0033] (1) Add 46.4g of 4-hydroxybutyl vinyl ether, 14.2g of acrylamide, 0.84g of β-hydroxyethyl methacrylate phosphate, and 552.96g of deionized water into a 1L four-necked flask, and stir evenly; Nitrogen gas was introduced into the flask to replace the air in the flask. After the monomers were completely dissolved, 0.61 g of sodium methacrylate and 0.92 g of ammonium persulfate were added, and stirred evenly;

[0034] (2) Adding 60 g of sodium sulfite solution with a mass fraction of 0.1% dropwise in the solution obtained in step (1), controlling the water bath at 30° C., the dropwise addition time is 2 h, and the dropwise addition is completed and incubated for 1 h; after the reaction is completed, add 30 wt % sodium hydroxide The...

Embodiment 2

[0037] A concrete viscosity reducer, the monomers involved are 4-hydroxybutyl vinyl ether, methacrylamide and acrylate-beta-hydroxyethyl phosphate, and its material ratio is 1:1:0.02. Its preparation The method includes the following steps:

[0038] (1) Add 46.4g of 4-hydroxybutyl vinyl ether, 33.95g of methacrylamide, 1.57g of β-hydroxyethyl acrylate phosphate, and 464.2g of deionized water into a 1L four-necked flask, and stir evenly; Nitrogen gas was introduced into the flask to replace the air in the flask. After the monomers were completely dissolved, 0.82 g of sodium methacrylate, 0.41 g of sodium allyl sulfonate, and 1.23 g of potassium persulfate were added, and stirred evenly;

[0039] (2) Add 41 g of sodium sulfite solution with a mass fraction of 0.1% dropwise to the solution obtained in step (1), control the water bath at 40° C., the drop time is 2.5 h, and keep the temperature for 1 h after the addition is completed; The sodium aqueous solution adjusts the pH to ...

Embodiment 3

[0042] A concrete viscosity reducer, the monomers involved are 4-hydroxybutyl vinyl ether, acrylamide, N-isopropylacrylamide and hydroxypropyl acrylate phosphate, and the molar ratio of the substances is 1:1:1 :0.03, its preparation method comprises the following steps:

[0043](1) Add 30g of 4-hydroxybutyl vinyl ether, 18.34g of acrylamide, 29.23g of N-isopropylacrylamide, 1.63g of hydroxypropyl acrylate phosphate, and 316.8g of deionized water into a 1L four-necked flask. Stir evenly; introduce nitrogen into the flask to replace the air in the bottle, after the monomers are completely dissolved, add 1.58g of sodium 2-acrylamido-2-methylpropenesulfonate, 0.40g of hydrogen peroxide, and stir evenly;

[0044] (2) Adding 40 g of L-ascorbic acid solution with a mass fraction of 0.2% in the solution obtained in step (1), controlling the water bath at 50° C., the time for adding is 3 hours, and the addition is completed and kept for 1 hour; after the reaction is completed, add 30 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com