Low-melting-point nylon wood/plastic product and preparation method thereof

A low-melting-point nylon technology, applied in the field of wood-plastic materials, low-melting-point nylon wood-plastic and its preparation, can solve problems such as low strength, high production cost, and environmental pollution, and achieve the effect of improving mechanical properties and avoiding degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

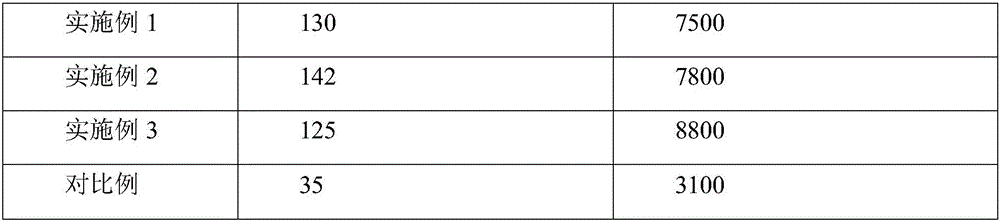

Examples

Embodiment 1

[0025] 1. Modified nylon: Dry nylon 6 and lithium chloride in an oven until the water content is below 0.1%, ball-mill lithium chloride in a ball mill, and pass through a 100-mesh sieve. The parts by weight of the following components are: Nylon 6: 95 parts; Lithium chloride: 5 parts. The two were mixed in an internal mixer for 5 minutes, and the temperature was set at 240 ° C. After mixing, the low melting point nylon 6 was crushed in the crusher.

[0026] 2. Wood-plastic preparation: The weight fractions of the following components are: low melting point nylon 6:50 parts, wood fiber: 40 parts, isocyanate chain extender: 5 parts, stearic acid: 3 parts, iron oxide red: 2 parts . The above materials are mixed in a mixer and granulated by a granulator, and the granulated material is extruded into shape.

Embodiment 2

[0028] 1. Modified nylon: Dry nylon 66 and calcium chloride in an oven until the water content is below 0.1%. After ball milling calcium chloride in a ball mill, pass through a 100-mesh screen. The parts by weight of the following components are respectively Nylon 66: 85 parts; Lithium chloride: 15 parts. Mix the two in an internal mixer for 6 minutes, set the temperature at 260°C, and crush the low-melting nylon 66 after mixing in a crusher.

[0029] 2. Wood-plastic preparation: the weight fractions of the following components are: low melting point nylon 66:80 parts, wood fiber: 15 parts, zinc stearate: 3 parts, iron oxide yellow: 2 parts. The above materials are mixed in a mixer and granulated by a granulator, and the granulated material is injection molded.

Embodiment 3

[0031] 1. Modified nylon: Dry nylon 6 and lithium chloride in an oven until the moisture content is below 0.1%, mill lithium chloride in a ball mill, and pass through a 80-mesh screen. The parts by weight of the following components are respectively: Nylon 6: 97 parts; Lithium chloride: 3 parts, the two are mixed in a mixer, and then granulated, and the temperature of each zone is set as follows:

[0032] interval

[0033] 2. Wood-plastic preparation: The weight fractions of the following components are: low melting point nylon 6:30 parts, wood fiber: 60 parts, epoxy resin chain extender: 5 parts, zinc stearate: 3 parts, iron oxide yellow : 2 servings. The above materials are mixed in a mixer and granulated by a granulator, and the granulated material is extruded into shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com