Preparation method of aluminum hydroxide coated talc powder special for flame retardant cable material

A technology of aluminum hydroxide and talcum powder, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of insufficient flame retardancy of cables, and achieve high temperature and high pressure, easy fire and strong compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

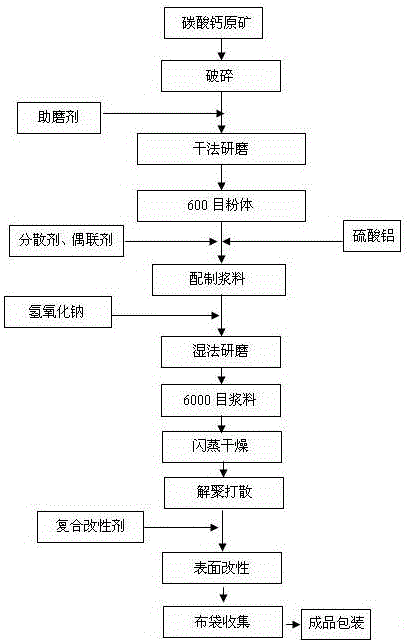

Method used

Image

Examples

Embodiment 1

[0019] The mass ratio of high-quality talcum powder and aluminum sulfate is 2:1 to make an aqueous solution with a solid content of 70%, and then add a polyacrylic acid sodium salt dispersant with a powder mass of 6‰ and a rare earth coupling agent of 3‰ [(C 3 h 7 O) x Re(OCOR′) m (OCOR 2 ) n (OAB) y 〕 compound dispersant, control the slurry temperature between 70-80°C for wet grinding and stirring, and finally prepare a 6000-mesh slurry, pump the stirred and reacted slurry into rapid flash drying, and decompose the powder 6000-mesh powder is obtained after polydispersing.

[0020] The powder is modified with a composite modifier, the modifier is 5‰ aluminate coupling agent, 3‰ stearic acid, 2‰ refined coconut oil and 2‰ alkylbenzene sulfonate Salt anionic surfactants. After modification, the high-speed stirred powder is packaged by an automatic packaging machine.

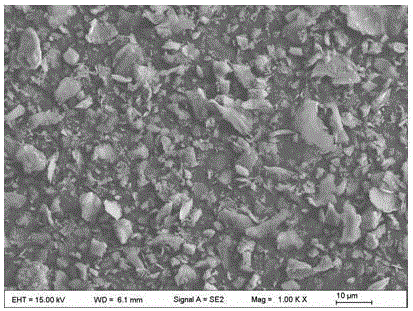

[0021] The electron micrograph of the aluminum hydroxide coated talcum powder that the present embodime...

Embodiment 2

[0023] The mass ratio of high-quality talcum powder and aluminum sulfate is 3:1 to make an aqueous solution with a solid content of 73%, and then add a polyacrylic acid sodium salt dispersant with a powder mass of 7‰ and a rare earth coupling agent of 4‰ [(C 3 h 7 O) x Re(OCOR′) m (OCOR 2 ) n (OAB) y 〕 compound dispersant, control the slurry temperature between 70-80°C for wet grinding and stirring, and finally prepare a 6000-mesh slurry, pump the stirred and reacted slurry into rapid flash drying, and decompose the powder 6000-mesh powder is obtained after polydispersing.

[0024] The powder is modified with a composite modifier. The modifiers are 6‰ of aluminate coupling agent, 4‰ of stearic acid, 3‰ of refined coconut oil and 3‰ of alkylbenzenesulfonate. Salt anionic surfactants. After modification, the high-speed stirred powder is packaged by an automatic packaging machine.

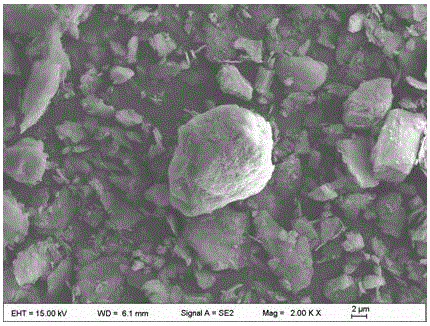

[0025] The electron micrograph of the aluminum hydroxide coated talcum powder that the pr...

Embodiment 3

[0027] The mass ratio of high-quality talcum powder and aluminum sulfate is 5:1 to make an aqueous solution with a solid content of 75%, and then add a polyacrylic acid sodium salt dispersant with a powder quality of 8‰ and a rare earth coupling agent of 5‰ [(C 3 h 7 O) x Re(OCOR′) m (OCOR 2 ) n (OAB) y 〕 compound dispersant, control the slurry temperature between 70-80°C for wet grinding and stirring, and finally prepare a 6000-mesh slurry, pump the stirred and reacted slurry into rapid flash drying, and decompose the powder 6000-mesh powder is obtained after polydispersing.

[0028] The powder is modified with a compound modifier, the modifier is an aluminate coupling agent of 7‰, stearic acid of 5‰, refined coconut oil of 5‰ and alkylbenzene sulfonate of 5‰ Salt anionic surfactants. After modification, the high-speed stirred powder is packaged by an automatic packaging machine.

[0029] The electron micrograph of the aluminum hydroxide coated talcum powder that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com