Doped high-infrared reflection rare-earth sesquisulfide gamma-Ce2S3 coated mica pearlescent pigment and preparation method thereof

A pearlescent pigment, infrared reflection technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of monotonous cerium sulfide, affecting the color of nuclear materials, and decreasing tinting strength, etc. High ultraviolet absorption and near-infrared reflection performance, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

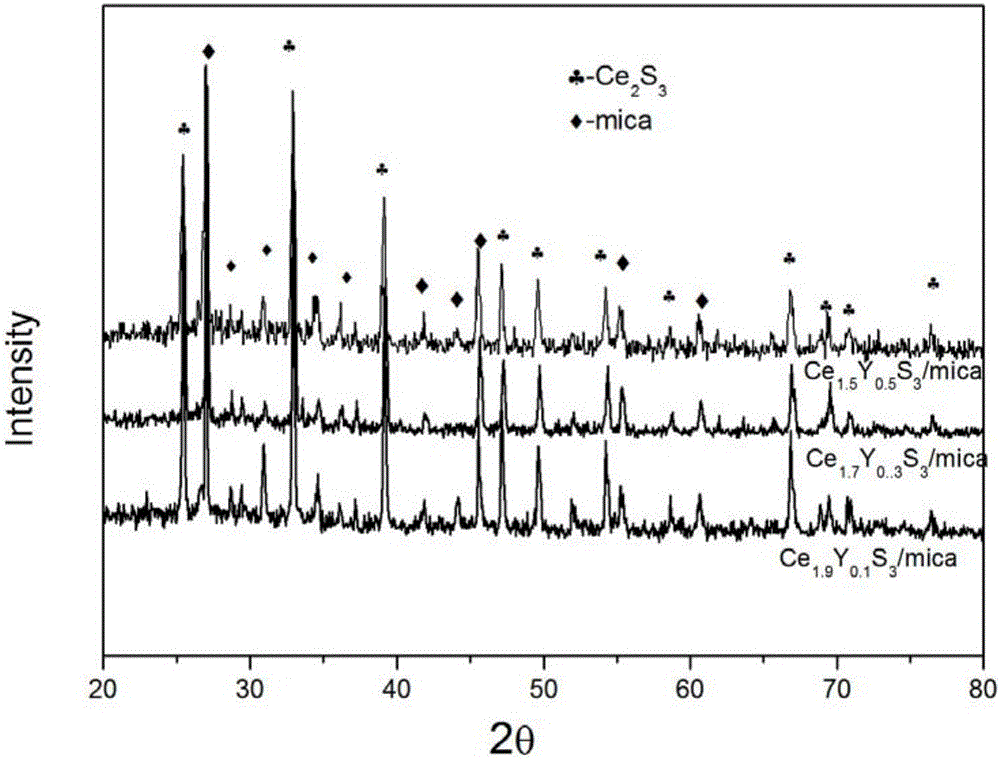

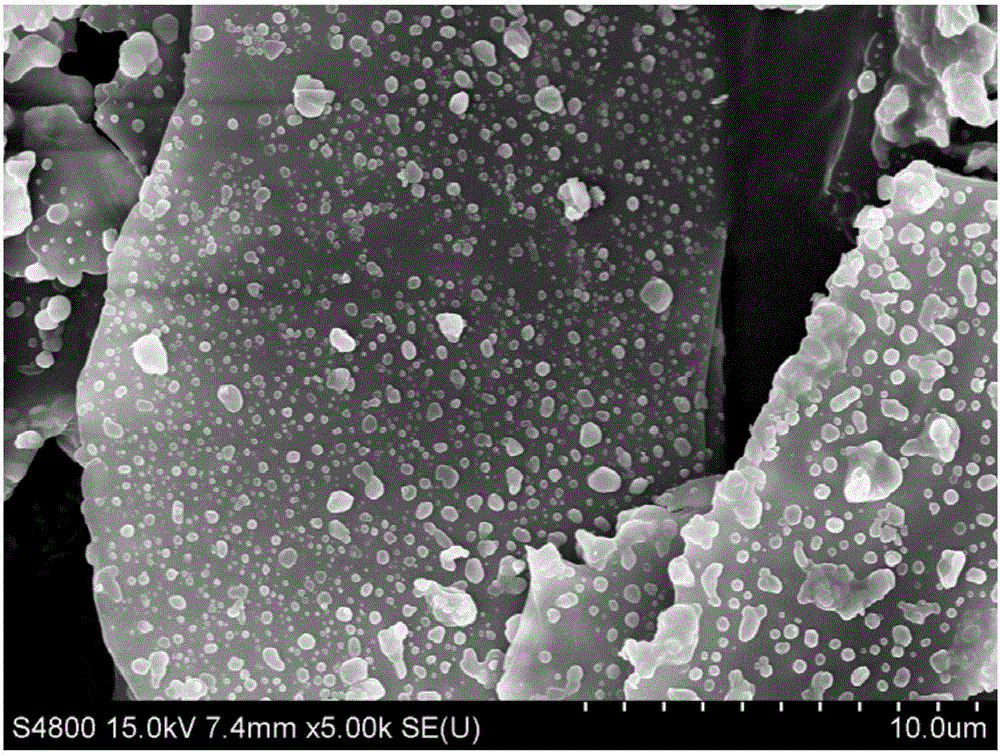

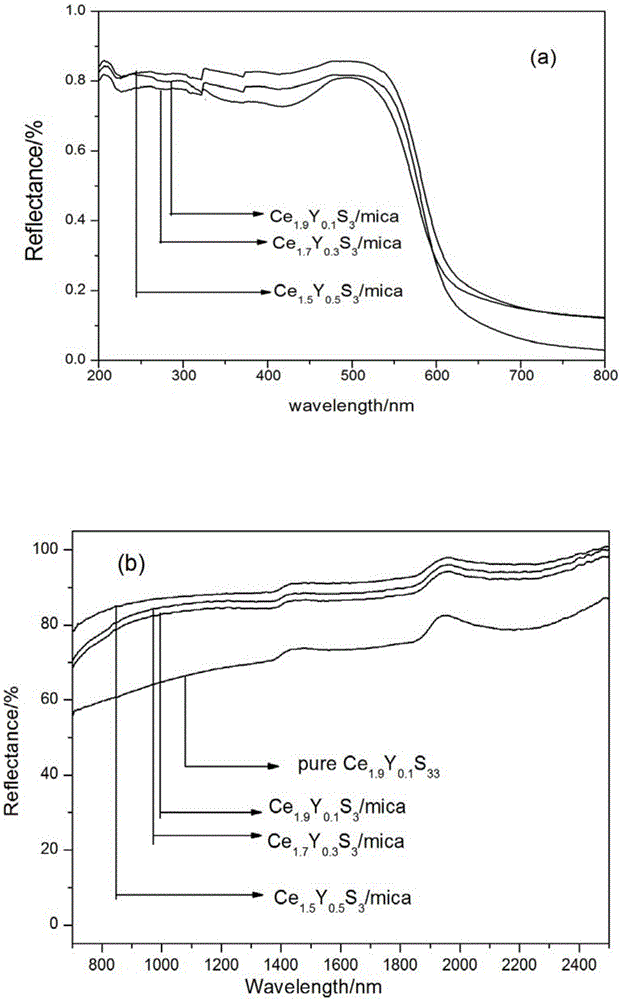

[0024] Example 1 Ce 2-x Y x S 3 (x=0.1) preparation of coated mica pearlescent pigment

[0025] (1) Mica pretreatment: hydrochloric acid with a mass fraction of 5wt.% and the solid-to-liquid ratio of mica is 1:10, stirred and cleaned in a water bath at 80°C for 30 minutes, filtered, washed, and dried, and 3g of pretreated mica was prepared to make 10wt .% mica slurry.

[0026] (2) Preparation of mixed oxide-coated mica pearlescent pigments: Ce(NO 3 ) 3 ·6H 2 O, Y (NO 3 ) 3 ·6H 2O, citric acid, acrylamide, and glucose weighed 1.425 g, 0.066 g, 2.18 g, 0.98 g, and 3 g respectively according to a certain stoichiometric ratio, dissolved in an appropriate amount of deionized water, then dropped into 5 ml of acetylacetone, and mixed with mica slurry to prepare 100ml suspension. Stir the suspension magnetically for 20 minutes and turn it to a water bath at 80°C for heating and stirring. Mix the suspension until it becomes viscous and stop stirring. Continue to keep warm unt...

Embodiment 2

[0028] Example 2 Ce 2-x Y x S 3 (x=0.3) preparation of coated mica pearlescent pigment

[0029] (1) Mica pretreatment: hydrochloric acid with a mass fraction of 5wt.% and the solid-to-liquid ratio of mica is 1:10, stirred and cleaned in a water bath at 80°C for 30 minutes, filtered, washed, and dried, and 3g of pretreated mica was prepared into 10wt .% mica slurry.

[0030] (2) Preparation of mixed oxide-coated mica pearlescent pigments: Ce(NO 3 ) 3 ·6H 2 O, Y (NO 3 ) 3 ·6H 2 O, citric acid, acrylamide, and glucose weighed 1.309g, 0.204g, 2.18g, 0.98g, and 3.5g respectively according to a certain stoichiometric ratio, dissolved in an appropriate amount of deionized water, then dropped into 4ml of acetylacetone, and mixed with mica slurry Prepare 100ml suspension. Stir the suspension magnetically for 30 minutes, turn it to a water bath with a temperature of 70°C, heat and stir, mix the suspension until it becomes viscous and stop stirring, then continue to keep warm u...

Embodiment 3

[0032] Example 3 Ce 2-x Y x S 3 (x=0.5) preparation of coated mica pearlescent pigment

[0033] (1) Mica pretreatment: hydrochloric acid with a mass fraction of 5wt.% and the solid-to-liquid ratio of mica is 1:10, stirred and cleaned in a water bath at 80°C for 30 minutes, filtered, washed, and dried, and 3g of pretreated mica was prepared into 10wt .% mica slurry.

[0034] (2) Preparation of mixed oxide-coated mica pearlescent pigments: Ce(NO 3 ) 3 ·6H 2 O, Y (NO 3 ) 3 ·6H 2 O, citric acid, acrylamide, and glucose weighed 1.155g, 0.340g, 2.18g, 0.98g, and 4g respectively according to a certain stoichiometric ratio, dissolved in an appropriate amount of deionized water, then dropped into 3ml of acetylacetone, and mixed with mica slurry to prepare 100ml suspension. Stir the suspension magnetically for 40 minutes and turn it to a water bath at 75°C for heating and stirring. Mix the suspension until it becomes viscous and stop stirring. Continue to keep warm until gel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com