Preparation method and application of a bridge anti-icing type two-component polyurea waterproof coating

A waterproof coating and anti-icing technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of no anti-icing function, no super-hydrophobic properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

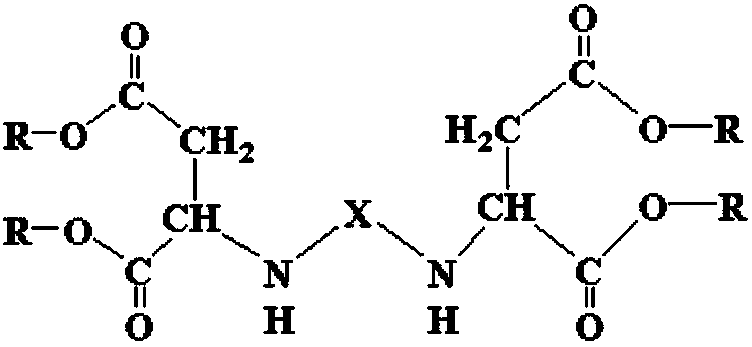

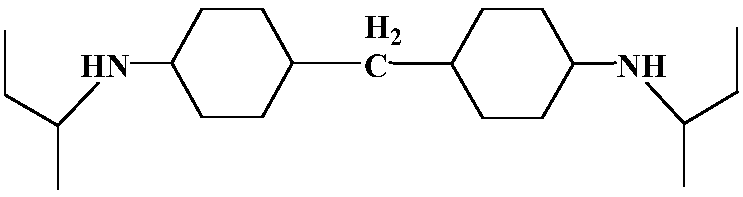

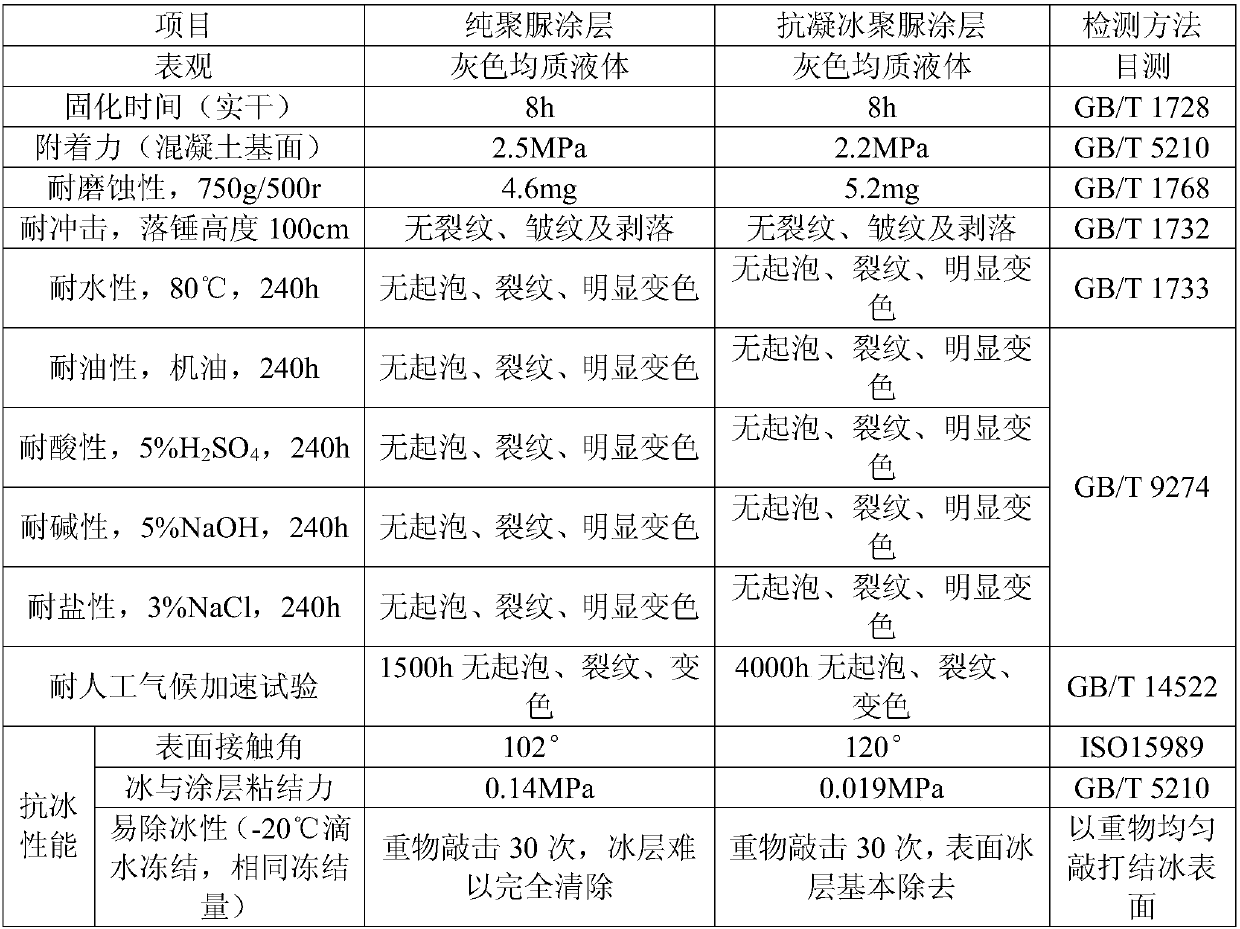

Method used

Image

Examples

Embodiment 1

[0101] (1) 200g polyether polyol N220, 18g polyester diol F1190, 50g perfluoropolyether diol Add Z-DOL (number average molecular weight 2000), 2g chain extender 2,2,3,3,4,4,5,5-octafluoro-1,6-hexanediol into the reaction vessel, vacuum degree -0.08MPa , After dehydration at 115°C for 3 hours (after dehydration, the moisture content is 0.025% measured by the Karl Fischer method), nitrogen or dry air is released to remove the vacuum, and the temperature is lowered to 68°C; 115.5g IPDI of isocyanate and 0.1g stannous octoate are added, and the temperature is constant After reacting for 30 minutes, raise the temperature to 75°C and react at a constant temperature for 2 hours. After the reaction is completed, cool down to 50°C, add 128.5g of dimethyl adipate and stir evenly to obtain a fluorine-modified polyurethane prepolymer component. The final isocyanate content of the prepolymer measured by the butylamine (GB / T 12009.4-1989) method is 6.1%;

[0102] (2) Add 400g of polyaspar...

Embodiment 2

[0106] (1) 196g polyether polyol N330, 14g polyester diol F1190, 30g perfluoropolyether diol Add Z-DOL (number average molecular weight 3000), 2.5g chain extender 1H,1H,8H,8H-dodecafluoro-1,8-octanediol into the reaction vessel, dehydrate under vacuum degree -0.09MPa, 120℃ for 2 Hours (after dehydration, the water content is 0.013% measured by the Karl Fischer method), nitrogen or dry air is released to remove the vacuum, and the temperature is lowered to 68 ° C; 141.4 g of isocyanate is added 12 MDI and catalyst 0.04g stannous octoate, react at constant temperature for 40min, heat up to 85°C for 2 hours, cool down to 60°C after completion of the reaction, add 53.5g of dimethyl succinate and stir evenly to obtain fluorine-modified polyurethane For the polymer component, the final isocyanate content of the prepolymer measured by the toluene-di-n-butylamine (GB / T12009.4-1989) method is 7.9%;

[0107] (2) Add 342g of polyaspartate NH1420, 100g of fluorocarbon resin LF-100, 3g o...

Embodiment 3

[0111] (1) 180g polyether polyol N240, 90g polyester diol Desmophen 670, 20g perfluoropolyether diol Add Z-DOL (number average molecular weight 4000), 5.4g chain extender 2,2,3,3-tetrafluoro-1,4-butanediol into the reaction vessel, dehydrate at vacuum degree -0.1MPa, 110℃ for 1.5 Hours (after dehydration, the moisture content is 0.022% measured by the Karl Fischer method), nitrogen or dry air is used to release the vacuum, and the temperature is lowered to 75°C; 305.26g of HDI trimer and 0.12g of stannous octoate catalyst are added, and after constant temperature reaction for 35min , heated up to 80°C for constant temperature reaction for 2.5 hours, cooled to 55°C after the reaction was completed, added 52.3g of ethyl acetate and 40g of butyl acetate and stirred evenly to obtain a fluorine-modified polyurethane prepolymer component, passed through toluene-di-n-butyl The final isocyanate content of the prepolymer measured by the amine (GB / T 12009.4-1989) method is 6.5%;

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com