Preparation method of graphene-containing energy storage polymer electrode sheet

A graphene and polymer technology, applied in the field of material science, can solve the problems of environmental protection recycling of electrode waste and other problems, and achieve the effects of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Mix the graphene powder and adhesive obtained by the modified hummers method in an agate mortar, grind them evenly, adjust the viscosity to 600-1000mpa.s with a solvent, and prepare energy storage latex for later use; After cationic naphthalene diimide is modified, it is reduced to anion with sodium thiosulfate in aqueous solution or formamide, and the water is volatilized under the protection of argon to generate conductive hyperbranched polymer powder. The modified polyamide-amine is rheologically prepared into a film with formamide as a solvent, and the energy storage latex is sprayed on the surface of the film at the same time, pressed by a pressure roller, and quickly dried with heat radiation and infrared assistance to make an electrode sheet.

Embodiment 2

[0035]Mix the graphene powder and adhesive obtained by the modified hummers method in an agate mortar, grind them evenly, adjust the viscosity to 600-1000mpa.s with a solvent, and prepare energy storage latex for later use; Coating on the base polyester material first, adding aniline dissolved in an acidic solution, and making a polyaniline film through chemical polymerization rheology, compounding the film with energy storage latex, applying pressure through a pressure roller, and using heat radiation, Infrared assisted rapid drying to make electrode sheets.

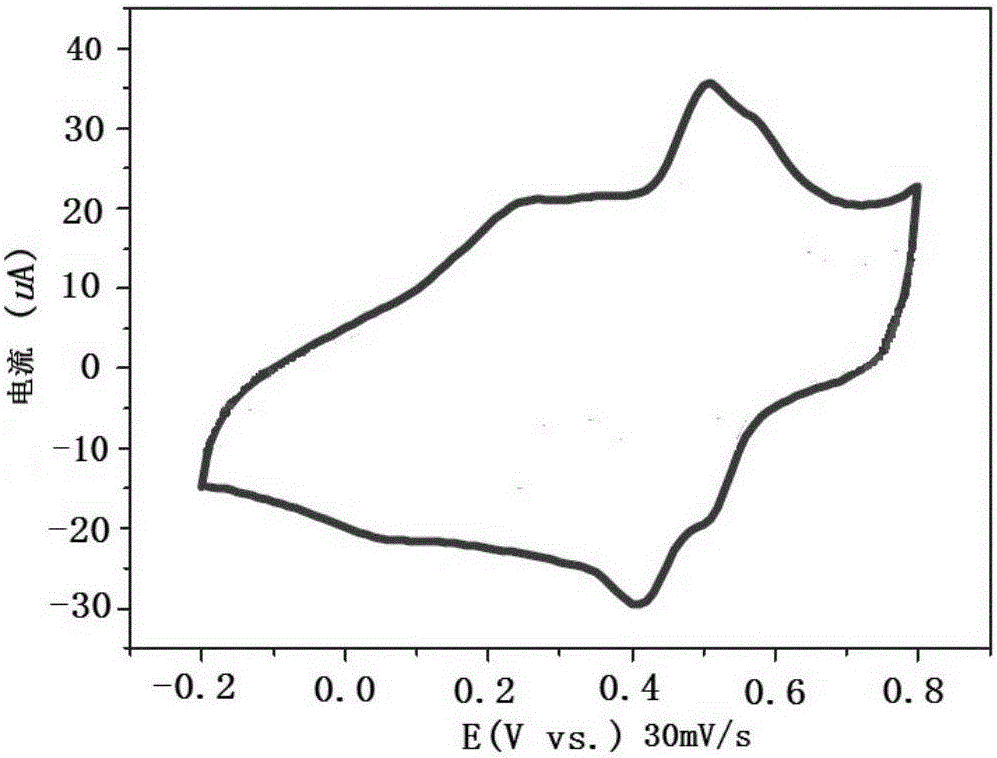

[0036] The electrode sheet obtained in Example 1 was tested by cyclic voltammetry, and the CV scanning speed was 0.000001 V / s to 10000 V / s. see results figure 1 , the CV curve of the energy storage capacitor, showing that a larger current density can be generated in a wider voltage range.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap