Silicon oxide-based silicon-oxygen-carbon composite material and preparation method and application thereof

A composite material, silicon oxycarbon technology, used in electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of pulverization and shedding of pole pieces, inability to meet commercialization, low coulomb efficiency, etc., to increase efficiency and thickness. , Excellent cycle stability, the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

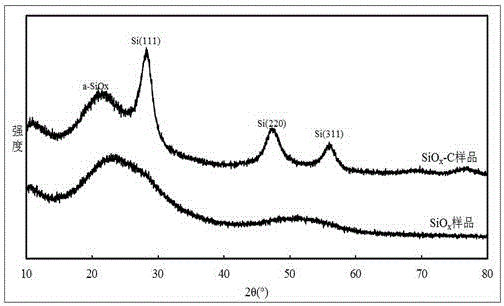

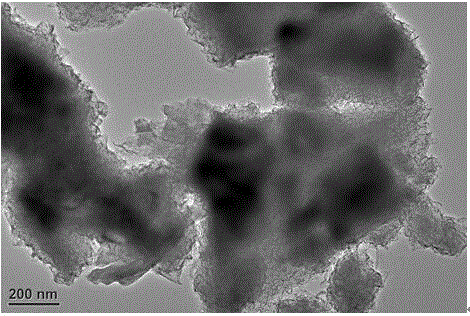

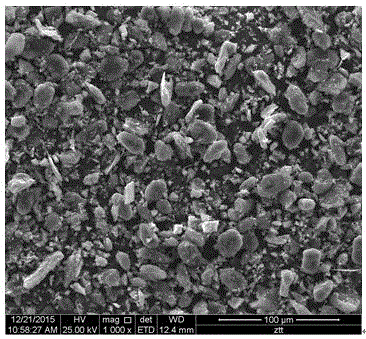

[0029] SiO x Matrix preparation: Si powder SiO 2 The powder is ball milled and mixed at a molar ratio of 1:1, and pressed into a block, and then the block is reacted in vacuum at 1300°C for 15 hours to obtain SiO x The agglomeration; The obtained agglomeration is carried out crushing ball mill, isopropanol is used as solvent, agate ball mill jar volume 50mL, agate ball and SiO x The mass ratio of the sample was 7:3, ball milled at 500rpm for 8h, and dried, then added polyethylene powder with a mass fraction of 1%, and ball milled in the same way to obtain SiO x powder.

[0030] SiOx -C material preparation: using a rotary furnace for thermal vapor deposition to coat carbon, the carbon source is a mixed gas of ethylene and argon, and a certain amount of prepared SiO is taken x The sample is placed in the center of the quartz tube of the rotary furnace, the inclination angle of the quartz tube is 5°, and the rotation speed is 10 rpm. Introduce argon gas to evacuate the air i...

Embodiment 2

[0036] SiO x Matrix preparation: Si powder SiO 2 The powder is ball milled and mixed at a molar ratio of 1.05:1, and pressed into a block, and then the block is reacted in vacuum at 1400°C for 20 hours to obtain SiO x The agglomeration obtained is crushed and ball milled, isopropanol is used as a solvent, the volume of the agate ball mill jar is 50mL, agate balls and SiO x The mass ratio of the sample was 7:3, ball milled at a speed of 500rpm for 8h, and dried, then added polyethylene powder with a mass fraction of 5%, and ball milled in the same way to obtain SiO x powder.

[0037] SiO x -C material preparation: use a rotary furnace for thermal vapor deposition to coat carbon, and the carbon source is a mixed gas of ethylene and argon. Take a certain amount of prepared SiO x The sample is placed in the center of the quartz tube of the rotary furnace, the inclination angle of the quartz tube is 5°, the rotation speed is 10rpm, the air in the tube is exhausted by passing a...

Embodiment 3

[0043] SiO x Matrix preparation: Si powder SiO 2 The powders were ball milled and mixed at a molar ratio of 1.05:1, and pressed into blocks, and then the blocks were reacted in vacuum at 1350°C for 15 hours to obtain SiO x of agglomerates. The obtained agglomerate is carried out crushing ball mill, isopropanol is used as solvent, agate ball mill jar volume 50mL, agate ball and SiO x The mass ratio of the sample was 7:3, ball milled at a speed of 500rpm for 8h, and dried, then added polyethylene powder with a mass fraction of 5%, and ball milled in the same way to obtain SiO x powder.

[0044] SiO x -C material preparation: use a rotary furnace for thermal vapor deposition to coat carbon, and the carbon source is a mixed gas of ethylene and argon. Take a certain amount of prepared SiO x The sample is placed in the center of the quartz tube of the rotary furnace, the inclination angle of the quartz tube is 5°, the rotation speed is 10rpm, the air in the tube is exhausted b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com