Industrial production method of furan derivative

A technology of furan derivatives and furan rings, which is applied in organic chemistry and other fields, can solve the problems of long compound synthesis routes, uneconomical atoms, complex by-products, etc., and achieve the effects of green production process, low raw material cost and convenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

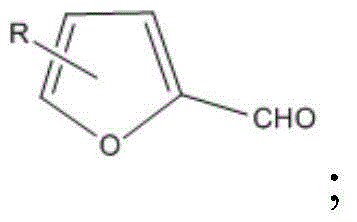

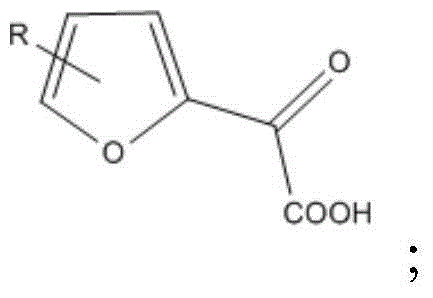

[0047] The reaction equation is as follows:

[0048]

[0049] Put 9600g of compound A into the reactor, add 2700g of HCN, stir and react at room temperature for 5 hours, then add 600g of nickel, feed air (or oxygen), and heat the system at a speed of 2-4°C / min while stirring to 60°C, react for 8 hours, and stop the reaction. (The reaction method with catalyst participation can also be used in the reaction process with HCN, such as: metal catalyst, biocatalyst, Lewis, etc.)

[0050] Cool to room temperature, add 1 L of water, stir for 1 hour, adjust the pH to weak acidity, filter, and recrystallize twice with a solvent of acetone:cyclohexane=1:1 to obtain 12999 g of product B.

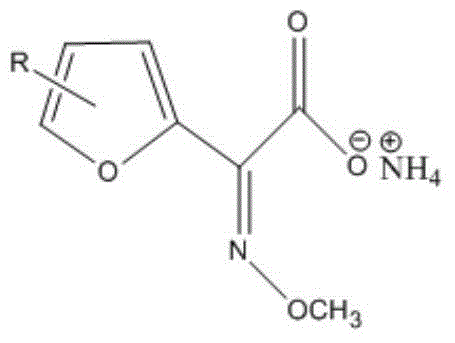

[0051] Or, after the above-mentioned reaction is finished, after cooling to room temperature, add 4700g of methoxyamine, adjust to an appropriate pH value with hydrochloric acid, and stir the reaction for 2 hours at room temperature, detect that the HPLC raw material is <5%, and feed 1700g of ammoni...

Embodiment 2

[0057] The reaction equation is as follows:

[0058]

[0059] Put 3000ml of acetonitrile, 9600g of compound A into the reaction kettle, add 4900g of NaCN and 100g of ion exchange resin at 25°C, stir and react for 1.5 hours, cool to room temperature, filter off the resin, evaporate the solvent, add 1L of water, and stir for 3 hours , add 100g of nickel, feed air (or oxygen), heat the system to 60°C at a speed of 2-4°C / min while stirring, react for 6 hours, and stop the reaction.

[0060] Cool to room temperature, add 1 L of water, stir for 1 hour, adjust the pH to weak acidity, filter, and recrystallize twice with a solvent of acetone:cyclohexane=1:1 to obtain 13132 g of product B.

[0061] Or, after the above-mentioned reaction is completed, after cooling to room temperature, add 4700g of methoxyamine, adjust to an appropriate pH value with hydrochloric acid, and stir the reaction for 2 hours at room temperature, detect that the HPLC raw material is <5%, and feed 1700g of amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com