Method for preparing monodisperse calcium alginate microspheres based on emulsion liquid film mass transfer

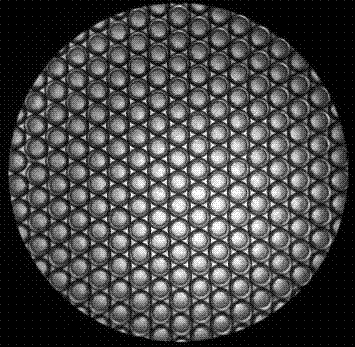

A calcium alginate and monodisperse technology, which is applied in the preparation of microspheres, pharmaceutical formulations, microcapsule preparations, etc., can solve the problems of difficult to achieve batch continuous production, cumbersome gel plate preparation process, and poor gel network uniformity , to achieve the effect of convenient batch continuous production, good size controllability and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

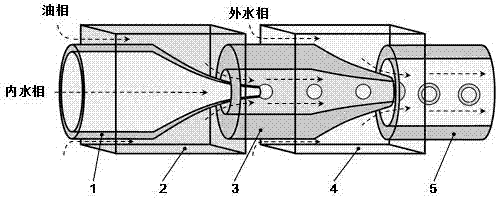

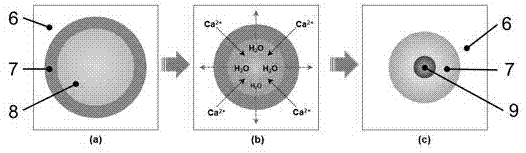

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of inner water phase, middle oil phase, outer water phase and collected water phase fluid

[0041] Preparation of the inner water phase fluid: the inner water phase fluid is made of sodium alginate, water-soluble emulsifier Pluronic F127 and deionized water, the mass ratio of sodium alginate to deionized water is 0.010:1, and the water-soluble emulsifier Pluronic F127 The mass ratio to deionized water is 0.020:1; sodium alginate and water-soluble emulsifier Pluronic F127 are added to deionized water at normal pressure and room temperature and stirred until completely dissolved, and the resulting mixed solution is the internal water phase;

[0042] The configuration of the intermediate oil phase fluid: the intermediate oil phase is made of soybean oil, benzyl benzoate and oil-soluble emulsifier, the volume ratio of soybean oil and benzyl benzoate is 2:1, and the emulsifier is mixed with soybean oil and benzyl benzoate The mass ratio of the ester mixture i...

Embodiment 2

[0051] (1) Preparation of inner water phase, middle oil phase, outer water phase and collected water phase fluid

[0052] Preparation of the inner water phase fluid: the inner water phase fluid is made of sodium alginate, water-soluble emulsifier Pluronic F108 and deionized water, the mass ratio of sodium alginate to deionized water is 0.002:1, and the water-soluble emulsifier Pluronic F108 The mass ratio to deionized water is 0.005:1; sodium alginate and water-soluble emulsifier Pluronic F108 are added to deionized water at normal pressure and room temperature and stirred until completely dissolved, and the resulting mixed solution is the internal water phase;

[0053] The configuration of the intermediate oil phase fluid: the intermediate oil phase is made of soybean oil, benzyl benzoate and oil-soluble emulsifier, the volume ratio of soybean oil and benzyl benzoate is 4:1, the emulsifier and soybean oil and benzyl benzoate The mass ratio of the ester mixture is 0.020:1, and...

Embodiment 3

[0063] (1) Preparation of inner water phase, middle oil phase, outer water phase and collected water phase fluid

[0064] Preparation of the inner water phase fluid: the inner water phase fluid is made of sodium alginate, water-soluble emulsifier Pluronic F68 and deionized water, the mass ratio of sodium alginate to deionized water is 0.05:1, and the water-soluble emulsifier Pluronic F68 The mass ratio to deionized water is 0.010:1; sodium alginate and water-soluble emulsifier Pluronic F68 are added to deionized water at normal pressure and room temperature and stirred until completely dissolved, and the resulting mixed solution is the internal water phase;

[0065] The configuration of the intermediate oil phase fluid: the intermediate oil phase is made of soybean oil, benzyl benzoate and oil-soluble emulsifier, the volume ratio of soybean oil and benzyl benzoate is 2:3, the emulsifier is mixed with soybean oil and benzyl benzoate The mass ratio of the ester mixture is 0.040:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com