Light-weight wave-absorbing material adopting interlayer structure and preparation method of wave-absorbing material

A wave-absorbing material and lightweight interlayer technology, which is applied in the field of fiber-absorbing materials, can solve problems such as difficulty in taking into account waterproof, flame-retardant and other properties, limit the practical application of wave-absorbing materials, and single absorption band, etc., and achieve easy large-scale mass production , light weight, good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

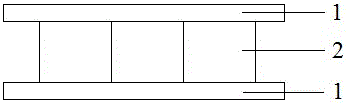

Method used

Image

Examples

Embodiment 1

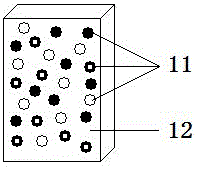

[0034] 1) Put the flake ferrite with a particle size of 10nm in butyl acetate for 30min;

[0035] 2), control the mass ratio of the sheet ferrite after the pretreatment in step 1 to the polyethylene substrate to be 20:80, and mix the two evenly, and prepare wave-absorbing polymer slices by melting, casting, and slicing ;

[0036] 3) Slicing the wave-absorbing polymer described in step 2, drying, melting, molding, forming, cooling, and demoulding to prepare wave-absorbing polymer structural parts and sheets, wherein the cross-section of the structural part is a regular octagon;

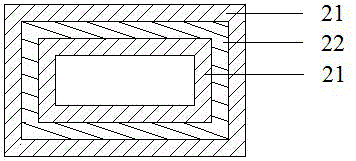

[0037] 4) In step 3, the inner and outer surfaces of the wave-absorbing polymer structural member are laminated with a wave-absorbing braided fabric made of vinylon fiber filaments and wave-absorbing fiber filaments at a mass ratio of 10:90 to prepare a structural wave-absorbing layer; wherein , Absorbing fiber filaments are prepared with 20nm irregular metal powder as the absorbing agent, polypropyle...

Embodiment 2

[0040] 1) Put rod-shaped silicon carbide with a particle size of 20nm and irregular metal powder with a particle size of 10nm in ethanol for 60min;

[0041]2), control the mass ratio of the rod-shaped silicon carbide and irregular metal powder after the pretreatment in step 1 to the polypropylene base material to be 30:70, and mix the two evenly, melt, cast, and slice to prepare the absorbent wave polymer slices;

[0042] 3) Slicing the wave-absorbing polymer described in step 2, drying, melting, molding, forming, cooling, and demoulding to prepare wave-absorbing polymer structural parts and sheets, the cross-section of which is circular;

[0043] 4) Lay the inner and outer surfaces of the wave-absorbing polymer structural part described in step 3 with the wave-absorbing braid woven with polytetrafluoroethylene fiber filaments and wave-absorbing fiber filaments at a mass ratio of 20:80 to prepare a structural wave-absorbing layer ; Among them, the wave-absorbing fiber filamen...

Embodiment 3

[0046] 1), placing the dendritic alloy powder with a particle size of 5nm in acetone for 20min;

[0047] 2), controlling the mass ratio of the dendritic alloy powder after the pretreatment described in step 1 to the polyethylene base material to be 30:70, and uniformly mixing the two, melting, casting, and slicing to prepare wave-absorbing polymer slices;

[0048] 3) Slicing the wave-absorbing polymer described in step 2, drying, melting, molding, forming, cooling, and demoulding to prepare wave-absorbing polymer structural parts and sheets, the cross-section of which is a regular quadrilateral;

[0049] 4) In step 3, the inner and outer surfaces of the wave-absorbing polymer structural member are laminated with polypropylene fiber filaments and wave-absorbing fiber filaments with a mass ratio of 20:80 to prepare a wave-absorbing layer; wherein, The wave-absorbing fiber filament is prepared with a mixture of 10nm spherical metal powder and 30nm flake carbon black as the wave a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com