Nanometer material with controllable particle sizes and silicon dioxide hollow spheres and method for preparing nanometer material

A technology of silica and nanomaterials, applied in the direction of silica, silica, nanotechnology for materials and surface science, etc., can solve the problem of unfavorable macromolecular object transportation and packaging, small pore size of silica hollow spheres, Problems such as emulsion template instability, to achieve the effect of good industrial application prospects, cheap raw materials, and low surfactant dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

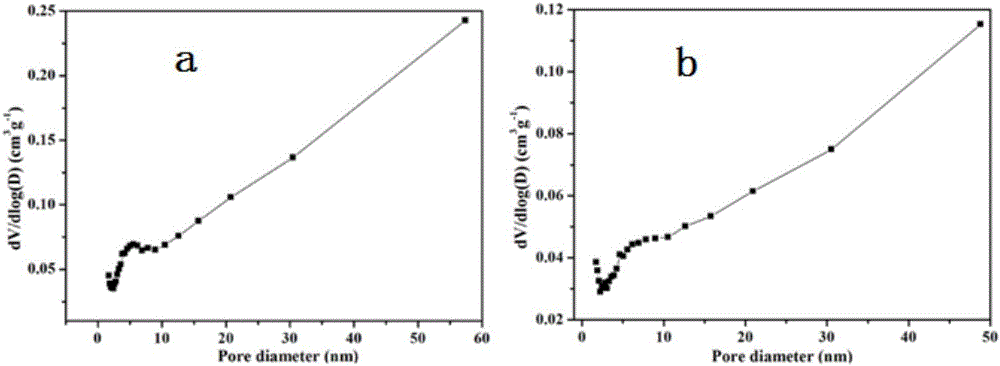

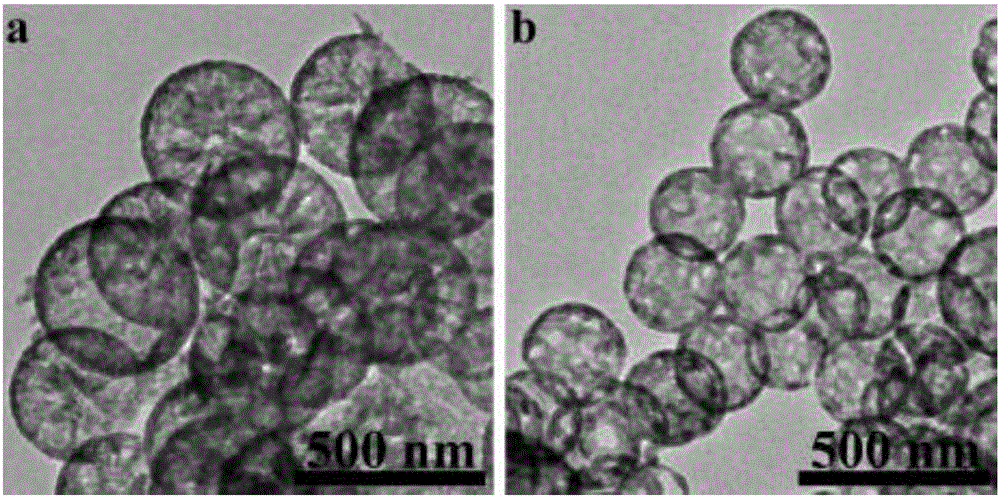

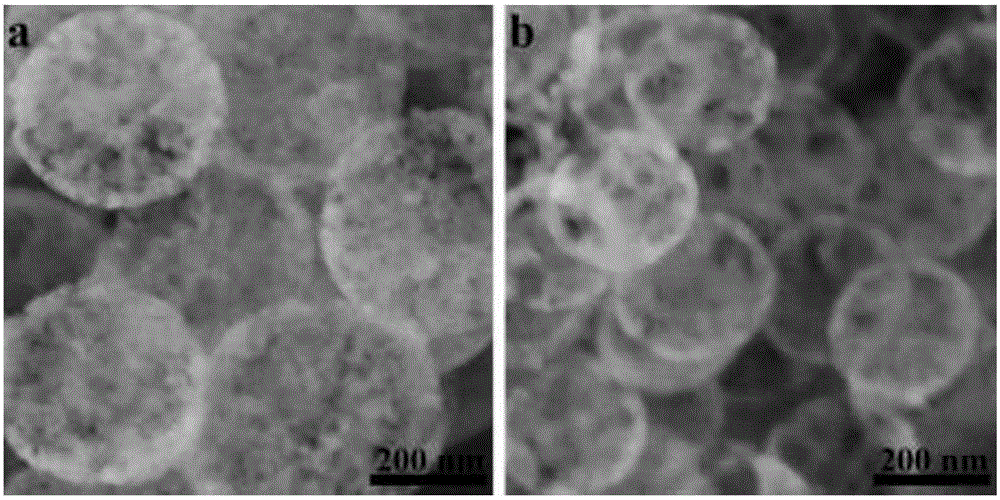

[0032]Add 0.04g CTAB and 1.50g PVP to the mixed solution composed of 20mL ethanol and 30mL deionized water in turn, stir at 30°C and 500rpm for 1h to obtain solution A; at room temperature, 1.20g TEOS was ultrasonically dispersed In 7mL of cyclohexane solution, under constant stirring, quickly add to solution A, continue to stir for 0.5h to form mixed solution B; add 0.7mL of ammonia water with a mass concentration of 27% to mixed solution B, and continue to stir at 30°C React for 2 hours to obtain solution C; transfer the mixed solution C to an autoclave, put the autoclave in an oven, and cool the autoclave to room temperature after solvothermal reaction at 180°C for 24 hours; centrifuge the obtained precipitate, wash it, and 60 After drying at ℃ for 10h, calcining at 550℃ for 5h in a box-type calciner to obtain the final product SiO 2 hollow ball.

[0033] FESEM ( figure 2 a) It can be clearly observed that the morphology of the sample is a sphere with a particle size of ...

Embodiment 2

[0035] Add 0.04g CTAB and 1.50g PVP to the mixed solution composed of 20mL ethanol and 30mL deionized water in turn, stir at 30°C and 500rpm for 1h to obtain solution A; at room temperature, 1.20g TEOS was ultrasonically dispersed In 7mL of cyclohexane solution, under constant stirring, quickly add to solution A, continue to stir for 0.5h to form mixed solution B; add 0.7mL of ammonia water with a mass concentration of 27% to mixed solution B, and continue to stir at 30°C React for 2 hours to obtain solution C; transfer the mixed solution C to an autoclave, put the autoclave in an oven, and cool the autoclave to room temperature after solvothermal reaction at 200°C for 24 hours; centrifuge the obtained precipitate, wash it, and After drying at ℃ for 10h, calcining at 550℃ for 5h in a box-type calciner to obtain the final product SiO 2 hollow ball.

[0036] FESEM ( figure 2 b) It can be clearly observed that the shape of the sample is a sphere with a particle size of 220-270...

Embodiment 3

[0038] Add 0.04g CTAB and 1.50g PVP to the mixed solution composed of 20mL ethanol and 20mL deionized water in turn, stir at 30°C and 500rpm for 1h to obtain solution A; at room temperature, ultrasonically disperse 1.20g TEOS In 8mL of cyclohexane solution, under constant stirring, quickly add to solution A, continue to stir for 0.5h to form mixed solution B; add 0.7mL of ammonia water with a mass concentration of 27% to mixed solution B, and continue to stir at 30°C React for 2 hours to obtain solution C; transfer the mixed solution C to an autoclave, put the autoclave in an oven, and cool the autoclave to room temperature after solvothermal reaction at 200°C for 24 hours; centrifuge the obtained precipitate, wash it, and After drying at ℃ for 10h, calcining at 550℃ for 5h in a box-type calciner to obtain the final product SiO 2 hollow ball. The particle size range of the prepared silica hollow sphere is 260-320nm, the shell thickness is 20nm, and the pore diameter is 12nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com