Synthesis method of glufosinate intermediate of methyl diethyl phosphite

A technology of diethyl methyl phosphite and diethyl methyl phosphite, which is applied in the field of synthesis of organophosphorus compounds, can solve problems affecting the company's normal production, unfavorable energy saving and emission reduction, and increased raw material costs, and achieves the elimination of Potential safety hazards, resource saving, and convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with three groups of comparative examples, the present invention is described in detail, so that content of the present invention is better understood, specifically as follows:

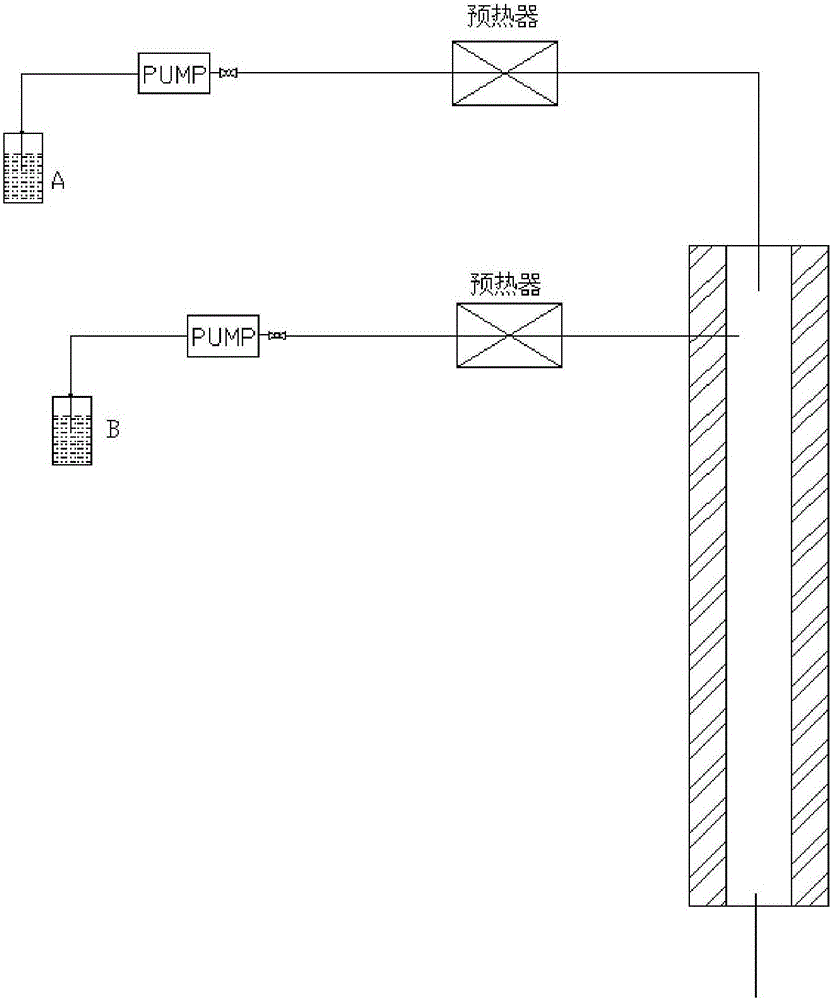

[0020] like figure 1 As shown, the synthesis effect of the glufosinate-ammonium intermediate diethyl methyl phosphite in the method of the embodiment of the present invention is evaluated by a tubular reactor, and the raw materials and products are analyzed by gas chromatography, and are specifically illustrated by the following three groups of examples , numbered A, B and C.

[0021] First group:

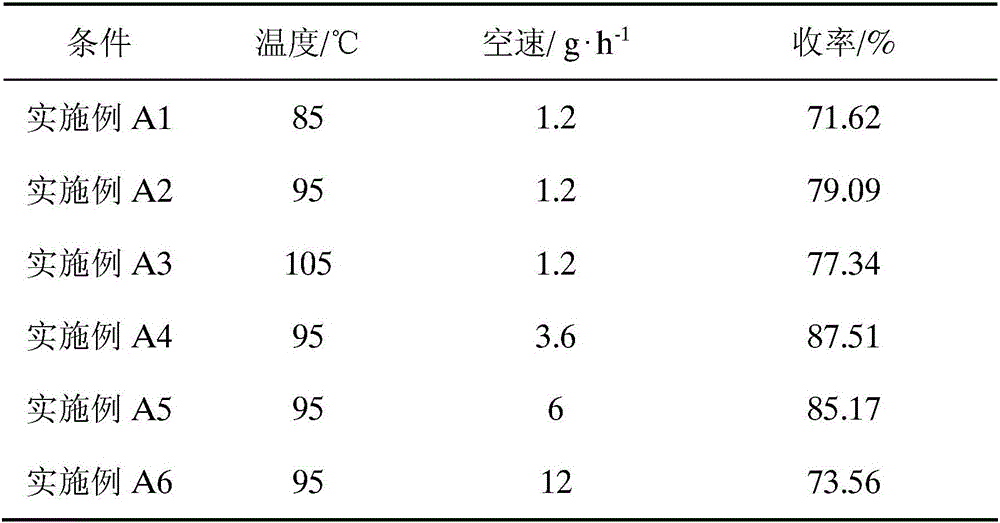

[0022] In the laboratory, a tubular reactor with an inner diameter of 32mm is used, filled with quartz sand as a filler, and adopts liquid phase continuous feeding addition reaction, the reaction pressure is 0.2MPa, and the molar ratio of MDP and ethanol is 1:5. The specific data is shown in the table below. 1:

[0023]

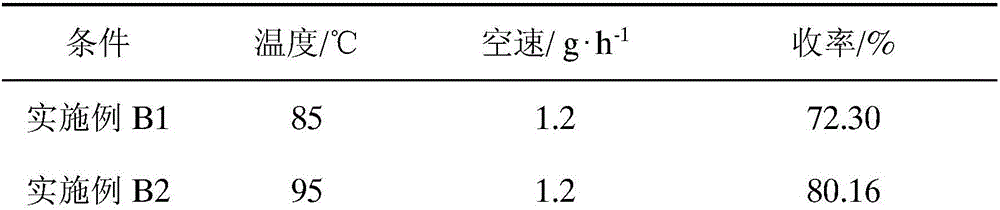

[0024] Second Group:

[0025] In the laboratory, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com