Preparation method of dialdehyde cellulose cross-linked chitosan film

A technology of cross-linking chitosan and cellulose, which is applied in the field of preparation of dialdehyde cellulose cross-linked chitosan film, can solve the problems that there are no reports of dialdehyde cellulose cross-linked chitosan film, and achieve high mechanical The effect of strength, less pollution and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

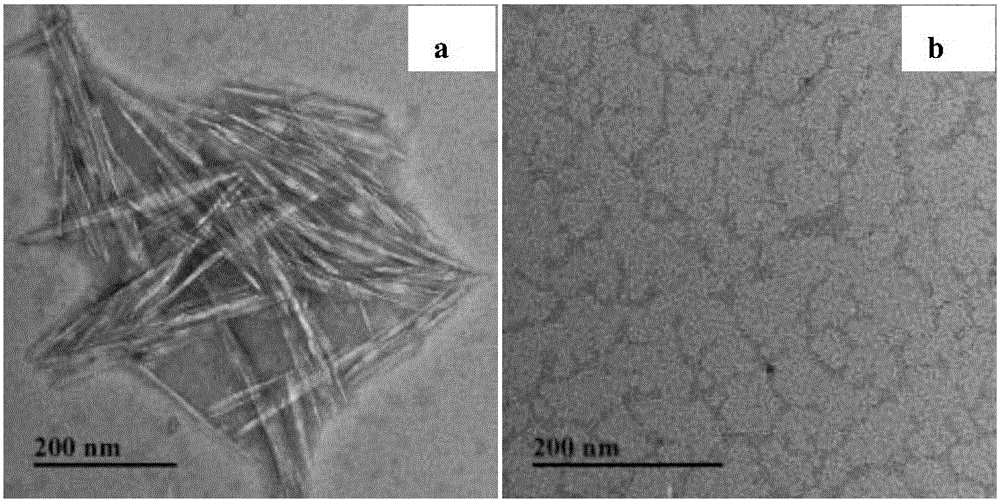

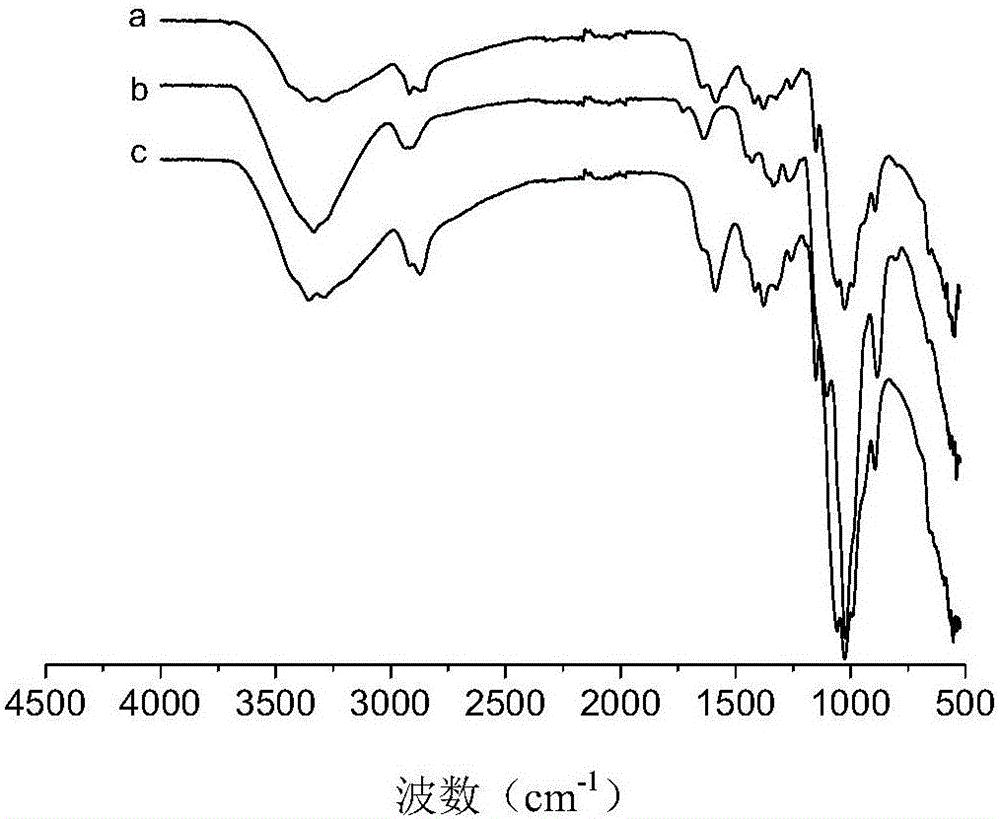

[0022] (1) Add 1 part of microcrystalline cellulose to 20 parts of 64% (w / v) concentrated sulfuric acid, mechanically stir at 45°C and 600r / min for 1h, centrifuge at 10000r / min at high speed, and collect the upper layer of white CNC colloid After 3 days of dialysis, add 0.1N sodium hydroxide solution to adjust the pH of the colloid to 6.5;

[0023] (2) Add 6.3 parts of sodium periodate to the CNC colloid prepared in step (1), react at 45°C for 4 hours in the dark; add 3 parts of ethylene glycol to react for 1 hour and dialyze for 5 days to obtain dialdehyde cellulose aqueous solution;

[0024] (3) under room temperature, adopt 1% (v / w) acetic acid solution to prepare 1% (w / w) chitosan solution, 1 part of dialdehyde cellulose aqueous solution prepared by step (2) and 100 parts of 1% The chitosan solution was mixed, vacuum defoamed, cast in a polytetrafluoroethylene mold, and dried at room temperature to form a film.

Embodiment 2

[0026] (1) Add 1 part of microcrystalline cellulose to 20 parts of 64% (w / v) concentrated sulfuric acid, mechanically stir at 45°C and 600r / min for 1h, centrifuge at 10000r / min at high speed, and collect the upper layer of white CNC colloid After 3 days of dialysis, add 0.1N sodium hydroxide solution to adjust the pH of the colloid to 6.5;

[0027] (2) Add 6.3 parts of sodium periodate to the CNC colloid prepared in step (1), react at 45°C for 4 hours in the dark; add 3 parts of ethylene glycol to react for 1 hour and dialyze for 5 days to obtain dialdehyde cellulose aqueous solution;

[0028] (3) under room temperature, adopt 1% (v / w) acetic acid solution to prepare 1% (w / w) chitosan solution, the dialdehyde cellulose aqueous solution prepared by 3 parts of steps (2) and 100 parts of 1% chitosan solution The chitosan solution was mixed, vacuum defoamed, cast in a polytetrafluoroethylene mold, and dried at room temperature to form a film.

Embodiment 3

[0030] (1) Add 1 part of microcrystalline cellulose to 20 parts of 64% (w / v) concentrated sulfuric acid, mechanically stir at 45°C and 600r / min for 1h, centrifuge at 10000r / min at high speed, and collect the upper layer of white CNC colloid After 3 days of dialysis, add 0.1N sodium hydroxide solution to adjust the pH of the colloid to 6.5;

[0031] (2) Add 6.3 parts of sodium periodate to the CNC colloid prepared in step (1), react at 45°C for 4 hours in the dark; add 3 parts of ethylene glycol to react for 1 hour and dialyze for 5 days to obtain dialdehyde cellulose aqueous solution;

[0032] (3) under room temperature, adopt 1% (v / w) acetic acid solution to prepare 1% (w / w) chitosan solution, the dialdehyde cellulose aqueous solution prepared by 5 parts of steps (2) and 100 parts of 1% chitosan solution The chitosan solution was mixed, vacuum defoamed, cast in a polytetrafluoroethylene mold, and dried at room temperature to form a film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com