Growth process capable of reducing barium boron oxide (BBO) crystal envelope

A crystal growth and process technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of insufficient convection, easy to bring the envelope, affecting the crystal quality and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

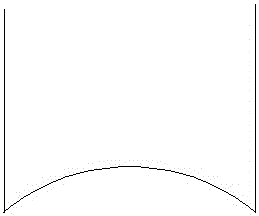

[0007] Example 1: Weigh a certain amount of barium carbonate, boric acid and sodium fluoride to meet BaB2O4:NaF=2:1 (molar ratio) and mix them in a raw material barrel. Melt the mixed material in a silicon carbide rod furnace at 1000°C until the reaction is complete. Pour the molten material into a platinum crucible with an inwardly convex arc at the bottom, then place it in a molten salt furnace, raise the temperature to 980°C, keep the temperature constant for 18 hours, and then set it at 10°C above the saturation temperature. Slowly lower the seed crystal previously fixed on the seed rod to the surface of the melt, rotate it at 4-10r / min, and the crystal begins to grow. When the crystal grows fast to the crucible wall, stop the crystal rotation, and start at 1°C / day. The temperature is lowered at a rate until about 6 months, the growth stops, and the BBO crystal blank is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com