Mushroom-type food fresh-keeping packaging material and preparation method thereof

A technology for food preservation and packaging materials, applied in the field of packaging materials, can solve the problems of single function, increase the burden of manpower and financial resources on consumers, and other problems, such as hidden dangers of food safety for consumers, and achieves simple preparation method, protection of integrity, excellent physical and chemical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

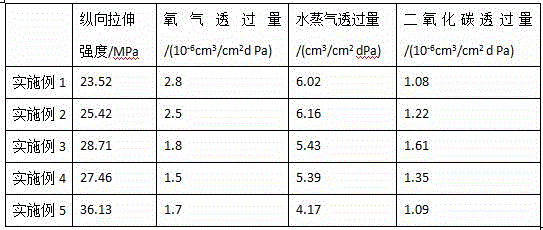

Examples

Embodiment 1

[0019] A fresh-keeping packaging material for mushroom food, the components and the mass parts of each component are as follows: 30 parts of polyvinyl chloride, 15 parts of polyethylene, 5 parts of epoxy soybean oil, 1 part of chlorinated paraffin, 2 parts of epoxy linseed oil 5 parts of nano-silica, 0.1 part of sodium bisulfite, 0.5 part of dioctyl phthalate, 6 parts of pentaerythritol, 2 parts of aluminum oxide as a coupling agent, and 1 part of dibutyltin dilaurate as a stabilizer.

[0020] The preparation method comprises the steps of:

[0021] 1) According to the mass ratio, polyvinyl chloride, polyethylene, epoxy soybean oil, chlorinated paraffin, epoxy linseed oil and nano silicon dioxide are mixed at high speed for 1~3 hours and then kneaded in a co-rotating twin-screw extruder Extruded, cooled in a cold water tank and cut to obtain the masterbatch; the speed of high-speed mixing is 13000rpm;

[0022] 2) Add the remaining components, mix well at 80°C, and blow the fil...

Embodiment 2

[0024] A fresh-keeping packaging material for mushroom food, the components and the mass parts of each component are as follows: 50 parts of polyvinyl chloride, 30 parts of polyethylene, 10 parts of epoxy soybean oil, 6 parts of chlorinated paraffin, 6 parts of epoxy linseed oil 10 parts of nano-silica, 0.8 parts of sodium bisulfite, 2.5 parts of dioctyl phthalate, 12 parts of pentaerythritol, 6 parts of aluminum oxide as a coupling agent, and 5 parts of dibutyltin dilaurate as a stabilizer.

[0025] The preparation method comprises the steps of:

[0026] 1) According to the mass ratio, polyvinyl chloride, polyethylene, epoxy soybean oil, chlorinated paraffin, epoxy linseed oil and nano silicon dioxide are mixed at high speed for 1~3 hours and then kneaded in a co-rotating twin-screw extruder Extruded, cooled in a cold water tank and cut to obtain the masterbatch; the speed of high-speed mixing is 13000rpm;

[0027] 2) Add the remaining components, mix well at 80°C, and blow ...

Embodiment 3

[0029] A fresh-keeping packaging material for mushroom food, the components and the mass parts of each component are as follows: 35 parts of polyvinyl chloride, 20 parts of polyethylene, 6 parts of epoxy soybean oil, 2 parts of chlorinated paraffin, 3 parts of epoxy flax oil 6 parts of nano-silica, 0.3 parts of sodium bisulfite, 1.2 parts of dioctyl phthalate, 8 parts of pentaerythritol, 3 parts of coupling agent aluminum oxide, and 2 parts of stabilizer dibutyltin dilaurate.

[0030] The preparation method comprises the steps of:

[0031] 1) According to the mass ratio, polyvinyl chloride, polyethylene, epoxy soybean oil, chlorinated paraffin, epoxy linseed oil and nano silicon dioxide are mixed at high speed for 1~3 hours and then kneaded in a co-rotating twin-screw extruder Extruded, cooled in a cold water tank and cut to obtain the masterbatch; the speed of high-speed mixing is 13000rpm;

[0032] 2) Add the remaining components, mix well at 80°C, and blow the film with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com