Halogen-free flame retardant new-energy wire and cable material for charging piles

A wire and cable, new energy technology, applied in the field of wire and cable materials for halogen-free flame retardant new energy charging piles, to achieve the effects of high tear strength, good processability, and high tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

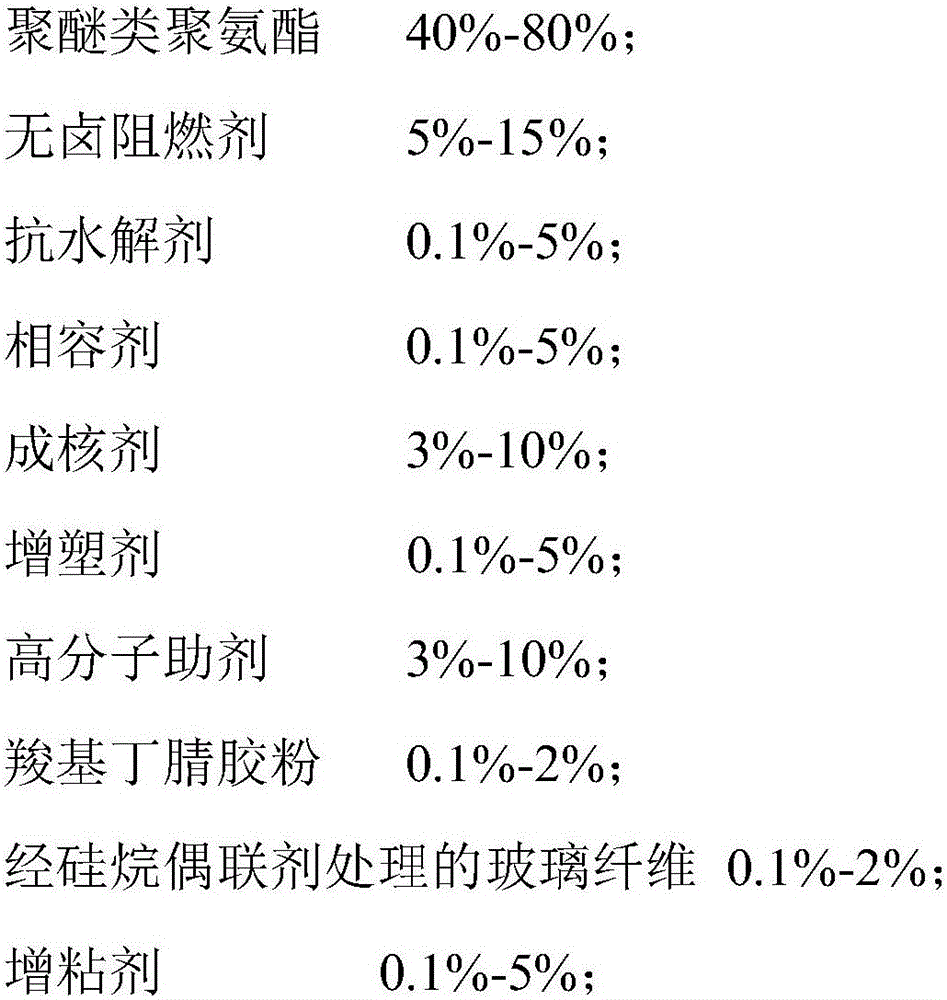

[0028] This embodiment provides a wire and cable material for a halogen-free flame-retardant new energy charging pile. In terms of mass percentage, the wire and cable material includes the following components:

[0029]

[0030]

[0031] Among them, the polymer additive is ABS, the halogen-free flame retardant is melamine cyanurate, the anti-hydrolysis agent is polycarbodiimide, the compatibilizer is maleic anhydride grafted SEBS, and the nucleating agent is polyol dicondensate. Aldehyde-alumina graft, plasticizer is epoxy vegetable oil, carboxyl nitrile rubber powder is core-shell structure, wherein core is nitrile rubber, shell is plastic carboxyl unsaturated hydrocarbon polymer, and its preparation method is: Copolymerize diene and acrylonitrile by emulsion copolymerization, then add carboxyl-containing unsaturated hydrocarbons, graft into powder by suspension grafting, then wash, dry, and pulverize; wherein, the carboxyl-containing The unsaturated hydrocarbon is acry...

Embodiment 2

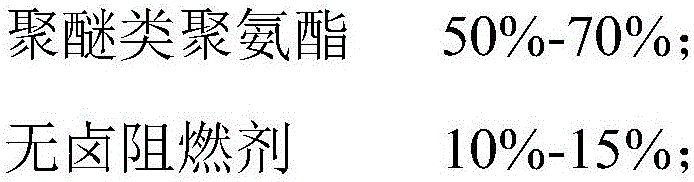

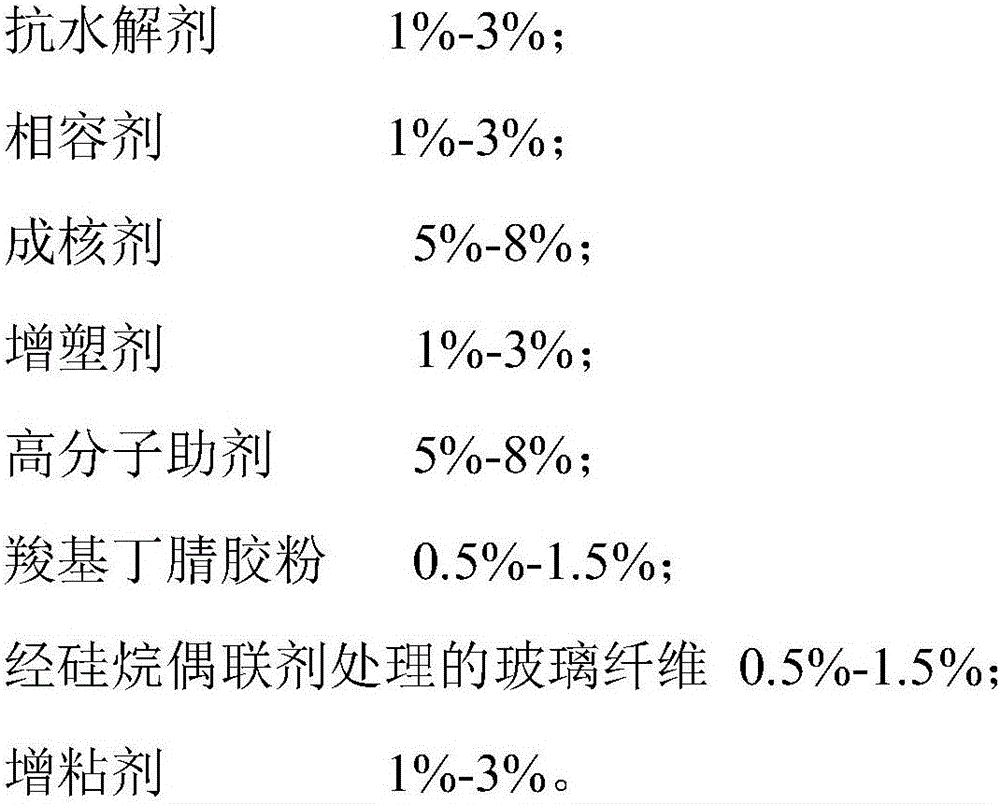

[0033] This embodiment provides a wire and cable material for a halogen-free flame-retardant new energy charging pile. In terms of mass percentage, the wire and cable material includes the following components:

[0034]

[0035] Among them, the polymer additive is PS, the halogen-free flame retardant is melamine polyphosphate, the anti-hydrolysis agent is biscarbodiimide, the compatibilizer is maleic anhydride grafted PE, and the nucleating agent is polyol diacetal - Alumina graft, plasticizer is naphthenic oil, carboxylated nitrile rubber powder is a core-shell structure, wherein the core is nitrile rubber, and the shell is plastic carboxyl unsaturated hydrocarbon polymer, and its preparation method is: Acrylonitrile and acrylonitrile are copolymerized by emulsion copolymerization, and then add carboxyl-containing unsaturated hydrocarbons, graft into powder by suspension grafting, then wash, dry, and pulverize; wherein, the carboxyl-containing unsaturated hydrocarbons The ...

Embodiment 3

[0037] This embodiment provides a wire and cable material for a halogen-free flame-retardant new energy charging pile. In terms of mass percentage, the wire and cable material includes the following components:

[0038]

[0039] Among them, the polymer additive is PBT, the halogen-free flame retardant is phosphate, the anti-hydrolysis agent is carbodiimide, the compatibilizer is maleic anhydride grafted PE, and the nucleating agent is polyol diacetal-alumina Graft, the plasticizer is white oil, and the carboxylated nitrile rubber powder has a core-shell structure, wherein the core is nitrile rubber, and the shell is a plastic carboxyl unsaturated hydrocarbon polymer. The preparation method is: butadiene and acrylonitrile Carry out copolymerization by emulsion copolymerization, then add carboxyl-containing unsaturated hydrocarbons, graft into powder by suspension grafting, then wash, dry, and pulverize; wherein, the carboxyl-containing unsaturated hydrocarbons are isobutylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com