Method and system for treating vanadium slag

A technology for vanadium slag and vanadium precipitation, applied to the system implementing the method, in the field of vanadium slag treatment, can solve problems such as iron recovery and waste of resources, and is suitable for continuous large-scale production, recovery rate improvement, and realization of easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

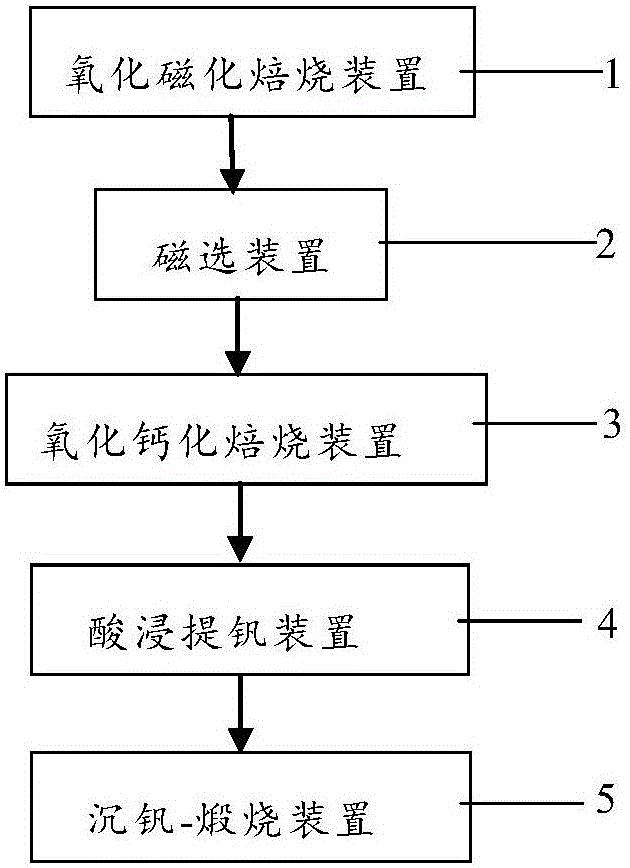

[0041] Embodiment 1 handles the method for vanadium slag

[0042] The vanadium slag (containing 35% of total iron and 16% of vanadium pentoxide) of a vanadium extraction and steelmaking plant in China was subjected to oxidation and magnetization roasting treatment in a rotary kiln at a temperature of 300°C, an oxygen concentration of 0.5%, and a roasting time of 5 minutes to obtain magnetic roasting Sand, wherein the iron in the ferroferric oxide accounts for 92% of the total iron; in the magnetic separation device (magnetic separator), the magnetic calcine is magnetically separated to obtain magnetic ferroferric oxide and vanadium-rich slag, and the iron is recovered Rate 90%. Vanadium-rich slag and calcium carbonate (analytical purity, content 99.5%) are mixed according to the weight ratio of vanadium-rich slag: calcium carbonate = 100:30, and the mixture is added to the tunnel kiln for calcification roasting and smelting. The smelting temperature is 800 ° C. The calcinatio...

Embodiment 2

[0043] Embodiment 2 handles the method for vanadium slag

[0044] The vanadium slag (containing 42% of total iron and 20% of vanadium pentoxide) of a vanadium extraction steelmaking plant in China was subjected to oxidation and magnetization roasting treatment in a rotary hearth furnace at a temperature of 400°C, an oxygen concentration of 1%, and a roasting time of 10 minutes to obtain magnetic Calcined sand, wherein the iron in ferroferric oxide accounts for 90% of the total iron; magnetically separates the magnetic calcined sand in a magnetic separation device (magnetic separator) to obtain magnetic ferroferric oxide and vanadium-rich slag, iron The recovery rate was 92%. Vanadium-rich slag and calcium oxide (analytically pure, content 99.5%) are mixed according to the weight ratio of vanadium-rich slag: calcium oxide = 100:5, and the mixture is added to the rotary kiln for calcification roasting and smelting. The smelting temperature is 1000 ° C. The calcination time is 2...

Embodiment 3

[0045] Embodiment 3 handles the method for vanadium slag

[0046] The vanadium slag (containing 25% of total iron and 14% of vanadium pentoxide) from a vanadium extraction and steelmaking plant in China was oxidized and magnetized roasted in a rotary hearth furnace at a temperature of 500°C, an oxygen concentration of 1.5%, and a roasting time of 15 minutes to obtain a magnetic Calcined sand, wherein the iron in ferroferric oxide accounts for 94% of the total iron; the magnetic calcined sand is magnetically separated in a magnetic separation device (magnetic separation tube) to obtain magnetic ferroferric oxide and vanadium-rich slag, iron The recovery rate is 95%. Vanadium-rich slag and calcium hydroxide (analytically pure, content 99.5%) are mixed according to the weight ratio of vanadium-rich slag: calcium hydroxide = 100:15, and the mixture is added to the rotary kiln for calcification roasting and smelting. The smelting temperature is 1100 ℃, roasting time 1h, to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com