A kind of degradable nano-short fiber material for tissue repair and its preparation method and application

A technology for tissue repair and nanofibers, applied in the field of degradable short nanofiber materials for tissue repair and its preparation, can solve the problems of unfavorable biomaterial biocompatibility, inability to disperse or disperse, and difficult to apply, so as to avoid nano Effects of fiber deformation, avoidance of void disappearance, good dispersion performance and repair performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

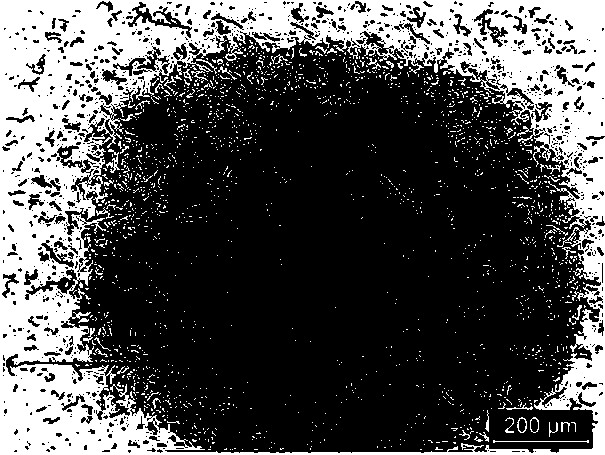

Image

Examples

Embodiment 1

[0071] Embodiment 1 Preparation of polylactic acid nano short fiber material

[0072] S1. Add 0.8g of polylactic acid into 10ml of hexafluoroisopropanol solution, stir at room temperature until dissolved, and make 8% (w / v) spinning solution; use deionized water as the solid liquid;

[0073] S2. Add the spinning solution into the syringe, add an extension tube to the front end of the syringe and connect a 20G needle, place the syringe on the micro-injection pump, the needle is perpendicular to the receiving plate, and the lower part of the receiving plate is grounded; set the injection rate to 2ml / h, when When the solution is extruded from the needle tip, a voltage of 22kv is applied to the needle tip; at this time, nanofibers are ejected and collected on the receiving plate to form a nanofiber film;

[0074] S3. Vacuum-dry the nanofibrous membrane for 48 hours to remove hexafluoroisopropanol, then transfer it to the solid liquid, repeatedly vacuum until it sinks to the bottom ...

Embodiment 2

[0077] Embodiment 2 Preparation of silk fibroin nano-short fiber material

[0078] S1. Add 1g of silk fibroin to 10ml of formic acid solution, stir at room temperature until dissolved, and make a 10% (w / v) spinning solution; use ethanol as the solid liquid and coagulation bath;

[0079] S2. Put the spinning solution into the syringe, add an extension tube to the front of the syringe and connect a 20G needle, place the syringe on the micro-injection pump, the needle is perpendicular to the crystallization dish, the crystallization dish is filled with the coagulation bath, and the lower part is grounded; set the injection rate 1ml / h, when the needle tip is extruded with a solution, a voltage of 18kv is applied to the needle tip; at this time, nanofibers are ejected and collected in the coagulation bath to form nanofiber clusters;

[0080] S3. In the case of replacing ethanol every 12 hours, soak the nanofibrous cluster in the coagulation bath for 48 hours to remove formic acid, ...

Embodiment 3

[0083] Example 3 Preparation of polyvinyl alcohol nano short fiber material

[0084] S1. Add 1g of polyvinyl alcohol into 10ml of deionized water, stir at 90°C until dissolved, and make a 10% (w / v) spinning solution; use methanol as the solid liquid;

[0085] S2. Add the spinning solution into the syringe, add an extension tube to the front end of the syringe and connect a 20G needle, place the syringe on the micro-injection pump, the needle is perpendicular to the receiving plate, and the receiving plate is grounded; set the injection rate to 1ml / h, when the needle tip When the solution is extruded, a voltage of 25kv is applied to the needle tip; at this time, nanofibers are ejected and collected on the receiving plate to form a nanofiber film;

[0086] S3. Since the solvent of polyvinyl alcohol is water, no additional removal is required, and it is directly transferred to the solid liquid, vacuumized, soaked for 5 minutes, and then taken out;

[0087] S4. Transfer the nanof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com