Electrochemical high-grade oxidation apparatus

An advanced oxidation and electrochemical technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of small specific surface area of plate electrodes, limited electrocatalytic activity, low current efficiency, etc., to achieve Improved processing capacity and current efficiency, increased contact area and time, and long life effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

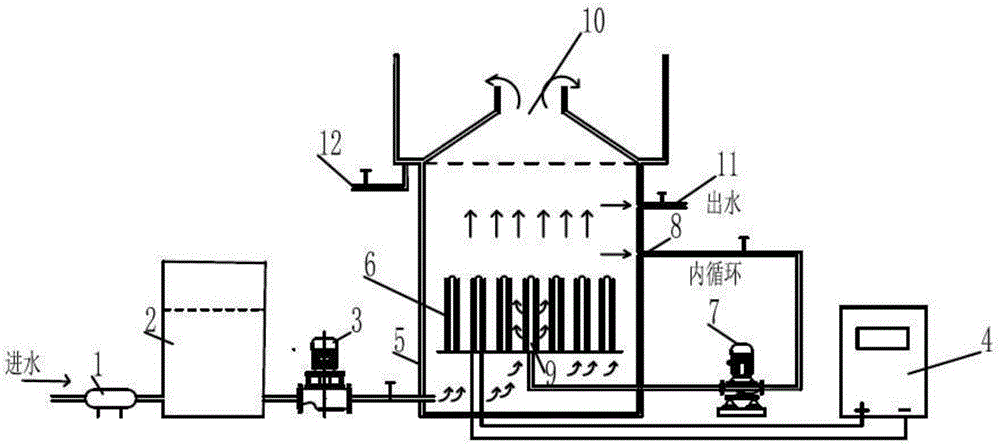

[0053] An electrochemical advanced oxidation device for treating refractory organic wastewater, characterized in that the device includes a pre-safety filter 1, an adjustable storage tank 2, a DC stabilized power supply 4, an advanced oxidation tank 5, and electrodes (arrays) 6 , Waste water internal circulation system and its booster pump 7 and air flotation defoaming zone 10. The regulating water storage tank 2 communicates with the pre-security filter 1 and the advanced oxidation tank 4 respectively, and a constant current pump 3 is arranged between the regulating water storage tank 2 and the advanced oxidation tank 4; 3 connected; the internal circulation booster pump 7 communicates with the oxidation pool internal circulation water outlet 8 and the anode cavity 9 respectively.

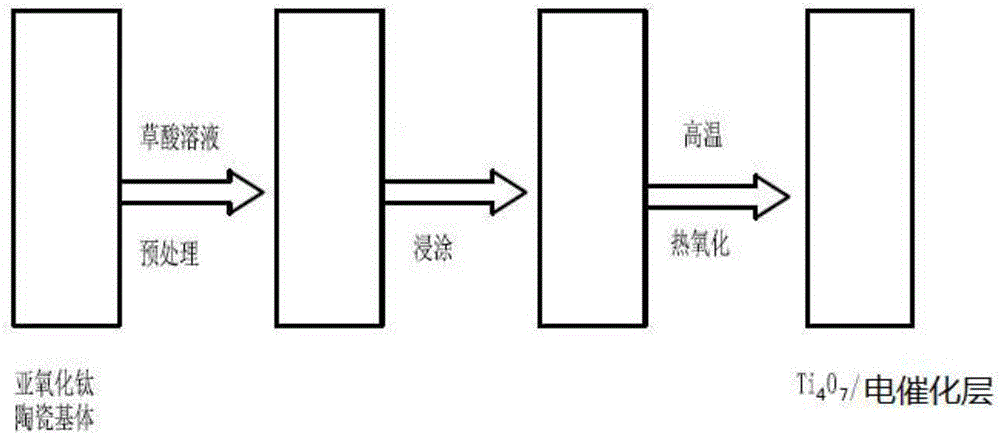

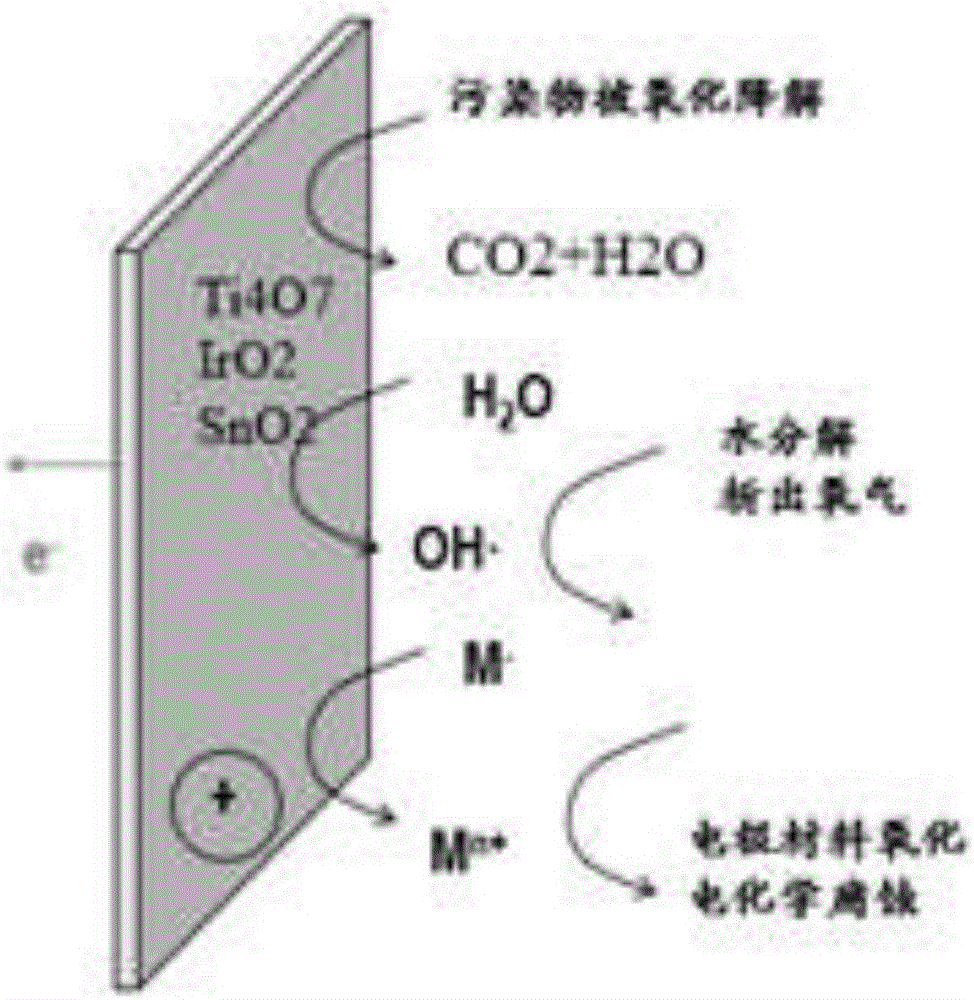

[0054] The anode of the electrode array connected to the power supply is a microporous tubular active electrochemical membrane anode, and its substrate is microporous titanium suboxide Ti 4 o 7 ...

Embodiment 2

[0065] according to image 3 Shown, the working process of the present invention is as follows:

[0066] 1. Install and fix the electrode array 6 composed of anode and cathode in the oxidation pool 5, connect the anode to the positive pole of the DC power supply 4, and connect the cathode to the negative pole;

[0067] 2. After removing the solid suspended matter through the pre-filter, the waste water enters the regulating storage tank, and decides whether to adjust the water quality according to the waste water condition;

[0068] 3. Turn on the constant flow pump 3, and make the wastewater enter the oxidation pond stably according to the designed flow rate;

[0069] 4. Turn on the DC stabilized power supply, adjust the current or voltage to the set value, and start electrochemical oxidation;

[0070] 5. When the water level in the oxidation pool reaches the height of the internal circulation water outlet 8, turn on the internal circulation booster pump 7 to allow the wast...

Embodiment 3

[0075] Using the device in Example 1 and the steps in Example 2 above to treat waste water from a paper mill in Shandong, the water quality is COD870mg / L, using constant current mode electrolytic oxidation, the control current is 12A, and the influent flow rate is 3L / hour. After one hour of catalytic oxidation, it was detected that the water COD dropped to 67mg / L, the removal rate was about 92%, and the operating cost was 8kwh / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com