Bismuth-silicon-boron low-melting-point nano glass powder suspension for glass jet drawing and preparation method

A low-melting-point glass and nano-glass technology, which is applied in the fields of glass decoration and glass printing, can solve the problems of high energy consumption, harmful environment, high production cost, etc., and achieve the effects of low melting temperature, not easy to settle, and high bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Bismuth-silicon-boron series low-melting-point nano-glass powder suspension for glass printing, the preparation method of which is as follows:

[0049] The present embodiment uses 500ml nylon ball mill jar, grinds 40g low-melting point glass powder at every turn, first according to bismuth oxide (α-type Bi 2 o 3 )31.4%, amorphous silicon oxide (SiO 2 ) 10.7%, boric acid (H 3 BO 3 )22%, lithium nitrate (LiNO 3 )32.3%, alumina (Al 2 o 3 )2.5%, zirconia (ZrO 2 ) 1.1% mass percentage, calculate the required raw material quality of ball milling 40g low-melting point glass powder, bismuth oxide (α-type Bi 2 o 3 ) 12.56 g, amorphous silicon oxide (SiO 2 ) 4.28 g, boric acid (H 3 BO 3 ) 8.8 grams, lithium nitrate (LiNO 3 ) 12.92 grams, alumina (Al 2 o 3 ) 1 g, zirconia (ZrO 2 )0.44 g and then weighed according to the calculation result.

[0050] Secondly, the weighed raw material bismuth oxide (α-type Bi 2 o 3 ), amorphous silicon oxide (SiO 2 ), alumina (Al ...

Embodiment 2

[0059] The experimental method of this embodiment is similar to that of the first embodiment, except that the mass percentages of the raw materials are different. According to bismuth oxide (α-type Bi 2 o 3 )29.8%, amorphous silicon oxide (SiO 2 ) 10.1%, boric acid (H 3 BO 3 )26.2%, lithium nitrate (LiNO 3 )30.6%, alumina (Al 2 o 3 )2.3%, zirconia (ZrO 2 ) 1% mass percentage, calculate the required raw material quality of ball milling 40g low-melting point glass powder, bismuth oxide (α-type Bi 2 o 3 ) 11.92 g, amorphous silicon oxide (SiO 2 ) 4.04 g, boric acid (H 3 BO 3 ) 10.48 g, lithium nitrate (LiNO 3 ) 12.24 grams, alumina (Al 2 o 3 ) 0.92 g, zirconia (ZrO 2 ) 0.4 gram, then weighed according to the calculation result, the following steps are completely consistent with embodiment 1.

[0060] The low-melting point nano-glass powder suspension obtained in this embodiment is white in color, similar in color and suspendability to the glass powder obtained in ...

Embodiment 3

[0065] The experimental method of this embodiment is similar to that of the first embodiment, except that the mass percentages of the raw materials are different. According to bismuth oxide (α-type Bi 2 o 3 )28.3%, amorphous silicon oxide (SiO 2 )9.6%, boric acid (H 3 BO 3 )29.8%, lithium nitrate (LiNO 3 ) 29.1%, alumina (Al 2 o 3 )2.2%, zirconia (ZrO 2 ) 1% mass percentage, calculate the required raw material quality of ball milling 40g low-melting point glass powder, bismuth oxide (α-type Bi 2 o 3 ) 11.32 g, amorphous silicon oxide (SiO 2 ) 3.84 g, boric acid (H 3 BO 3 ) 11.92 g, lithium nitrate (LiNO 3 ) 11.64 g, alumina (Al 2 o 3 ) 0.88 g, zirconia (ZrO 2 ) 0.4 gram, then weighed according to the calculation result, the following steps are completely consistent with embodiment 1.

[0066] The low-melting point nano-glass powder suspension obtained in this embodiment is white in color and similar in suspending property, which is similar in color to the glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

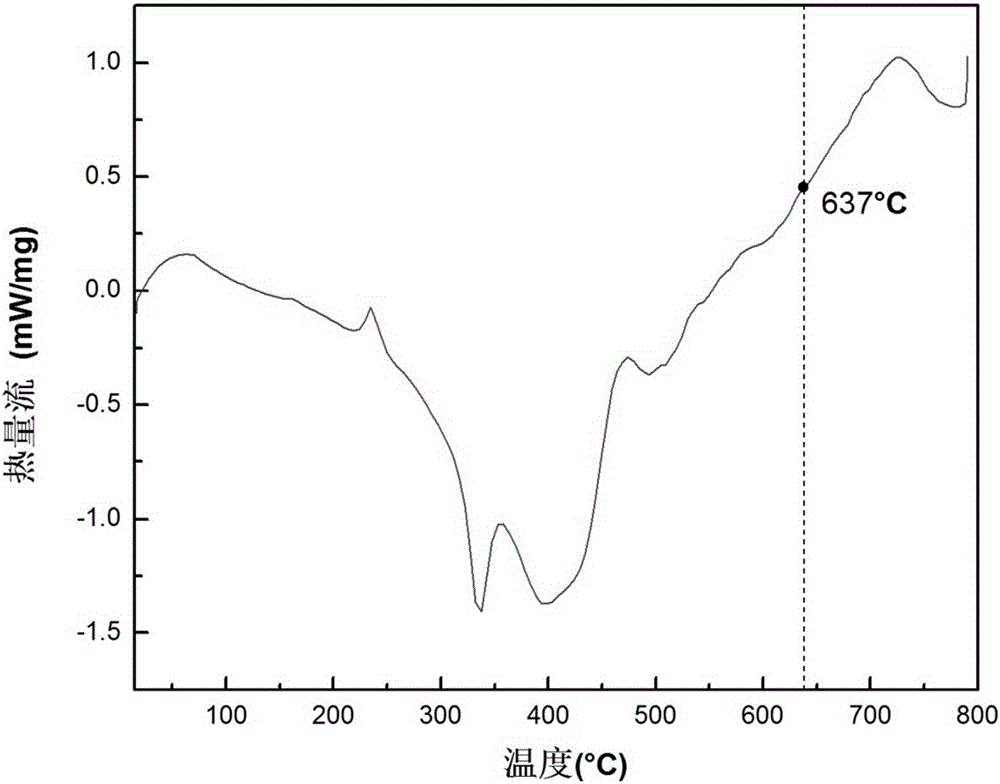

| softening point | aaaaa | aaaaa |

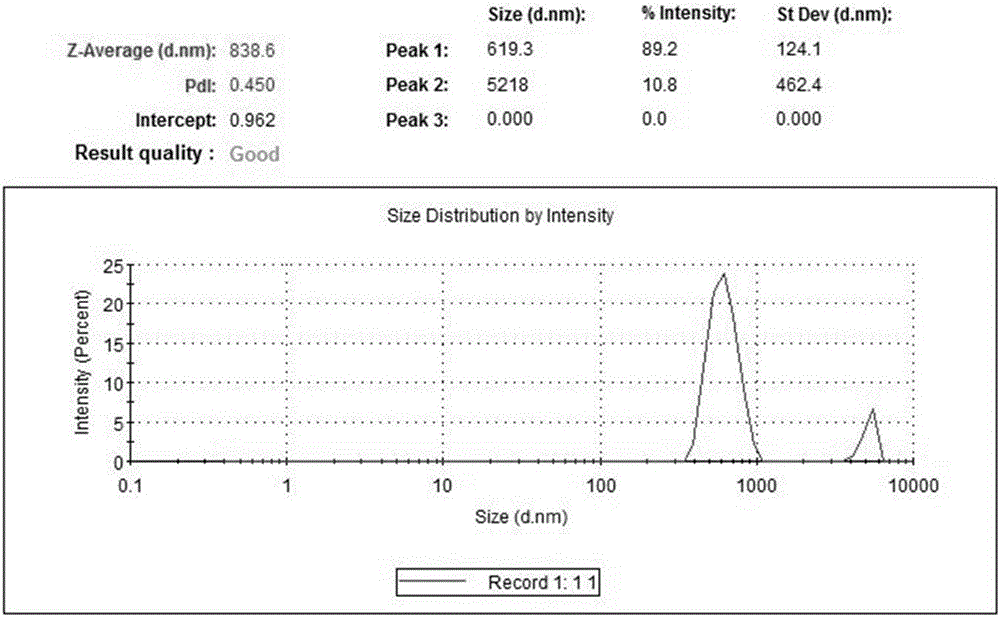

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com