Fig special-purpose fertilizer and preparation method thereof

A special fertilizer and fig technology, applied in the preparation of organic fertilizers, inorganic fertilizers, organic fertilizers, etc., can solve the problems of unscientific ratio of nutrients in various fertilizers, unable to meet the needs of fig growth, affecting the normal growth of figs, etc. Achieve the effect of significant fertilizer utilization rate, beneficial absorption and improvement of soil physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

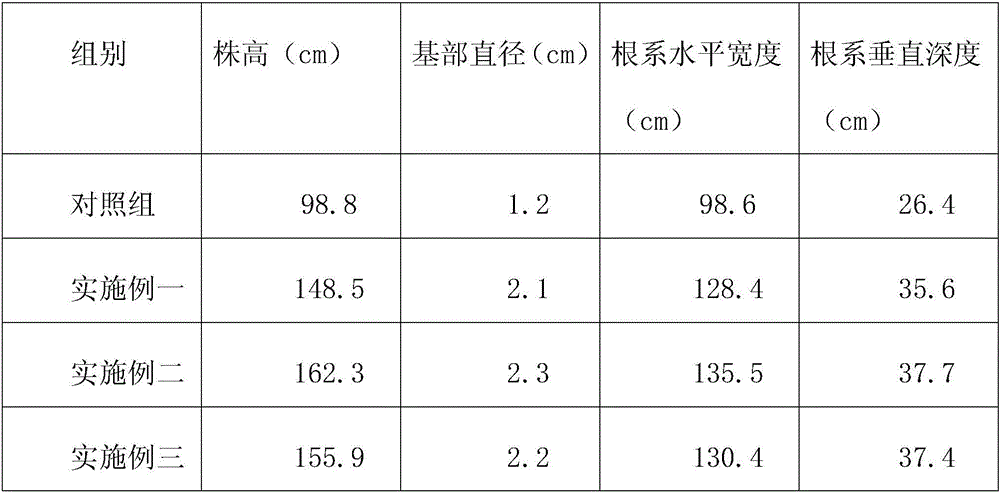

Embodiment 1

[0031] First, take 45 parts by weight of decomposed compost and 10 parts by weight of wheat straw according to the parts by weight of each component, put the two into a pulverizer and pulverize them and pass through a 10-mesh sieve, and then add the mixture according to each component to the mixture obtained by sieving. 10 parts by weight of plant ash taken by weight, add water and stir evenly, seal it, carry out anaerobic fermentation under normal temperature conditions for 40 days, turn over when the temperature reaches above 48°C, turn over once every 7 days later, Until the fermentation is completed, place the fermented mixture in a cool and ventilated place, let it air for 1 day, add 35 parts by weight of calcium magnesium phosphate fertilizer, 20 parts by weight of magnesium sulfate, and 20 parts by weight of superphosphoric acid Stir evenly after calcium, 15 parts by weight of slaked lime, continue to be placed in a cool and ventilated place to air for 2 days, then add 2...

Embodiment 2

[0033] First, take 55 parts by weight of decomposed compost and 20 parts by weight of wheat straw according to the parts by weight of each component, put the two into a pulverizer and pulverize them and pass through a 10-mesh sieve, and then add the mixture according to each component to the mixture obtained by sieving. 15 parts by weight of plant ash taken by weight, add water and stir evenly, seal it, carry out anaerobic fermentation under normal temperature conditions for 50 days, turn over when the temperature reaches above 48°C, turn over once every 7 days later, Until the fermentation is completed, place the fermented mixture in a cool and ventilated place, let it air for 2 days, add 45 parts by weight of calcium magnesium phosphate fertilizer, 30 parts by weight of magnesium sulfate, and 30 parts by weight of superphosphoric acid according to the parts by weight of each component. Stir evenly after calcium, 25 parts by weight of slaked lime, continue to be placed in a co...

Embodiment 3

[0035] First, take 50 parts by weight of decomposed compost and 15 parts by weight of wheat straw according to the parts by weight of each component, put the two into a pulverizer and pulverize them and pass through a 10-mesh sieve, and then add the mixture according to each component to the mixture obtained by sieving. The parts by weight of 12 parts by weight of plant ash, add water and stir evenly, seal it, carry out anaerobic fermentation under normal temperature conditions for 45 days, turn over when the temperature reaches above 48°C, turn over once every 7 days later, Until the fermentation is completed, place the fermented mixture in a cool and ventilated place, let it air for 2 days, add 40 parts by weight of calcium magnesium phosphate fertilizer, 25 parts by weight of magnesium sulfate, and 25 parts by weight of superphosphoric acid After calcium, 20 parts by weight of hydrated lime, stir evenly, continue to be placed in a cool and ventilated place to air for 2 days,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com