Graphene-based high-molecular nanometer alloy anti-wear self-repairing material, and preparation method and application thereof

A self-healing material, graphene-based technology, applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problem that graphite cannot prevent surface wear and corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A preparation method of a graphene-based polymer nano-alloy anti-wear self-repairing material, the steps are as follows:

[0061] (1) Preparation of Compound A

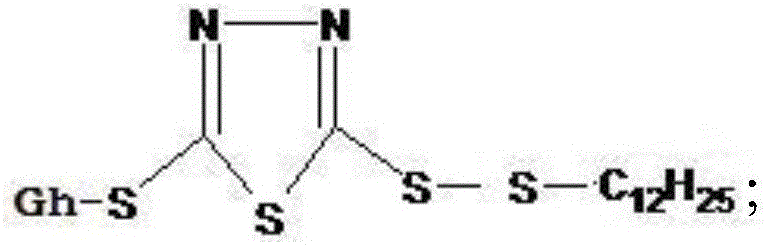

[0062] (1) Synthesis of oil-soluble thiadiazolidinylthio compounds

[0063] a. Add 1mol 2,5-dimercapto-1,3,4-thiadiazole DMTD, 300ml methanol, 300ml deionized water, 1.5ml KH560, 1ml polyethylene glycol into a four-necked flask equipped with a reflux condenser and a thermometer. Glycol ether and tributylamine mixture (weight ratio is 1:1), stirring and dissolving for 30min, and cooling the mixed solution to 0°C;

[0064] b. Add 32wt% NaOH solution dropwise to the mixed solution in step a through a high-position funnel, and finish adding dropwise within 2-5 hours, keep stirring and control the dropping speed, and control the temperature of the mixed solution not to exceed 20°C, and use an online pH meter When the pH value of the detection solution is 6.5-7.5, the reaction reaches the end point, and the mixed s...

Embodiment 2

[0085] A preparation method of a graphene-based polymer nano-alloy anti-wear self-repairing material, the steps are as follows:

[0086] (1) Preparation of Compound A

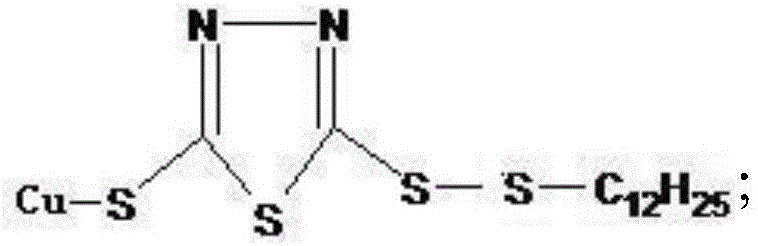

[0087] (1) Synthesis of alkylthio compounds of oil-soluble thiadiazole dimers

[0088] a. Add 1mol DMTD dimer, 300ml ethanol, 300ml deionized water, 1.5ml coupling agent KH570, 1ml polyethylene glycol ether and tributylamine mixture (weight ratio of 1:1), stirred and dissolved for 30 minutes, and cooled the mixed solution to 0°C;

[0089] b. Add 32wt% NaOH solution dropwise to the mixed solution in step a through a high-position funnel, and finish adding dropwise within 2-5 hours, keep stirring and control the dropping speed, and control the temperature of the mixed solution not to exceed 20°C, and use an online pH meter When the pH value of the detection solution is 6.5-7.5, the reaction reaches the end point, and the mixed solution is light yellow, clear and transparent liquid;

[0090] c. Add 1.0-1.5 mol ...

Embodiment 3

[0110] A preparation method of a graphene-based polymer nano-alloy anti-wear self-repairing material, the steps are as follows:

[0111] (1) Preparation of Compound A

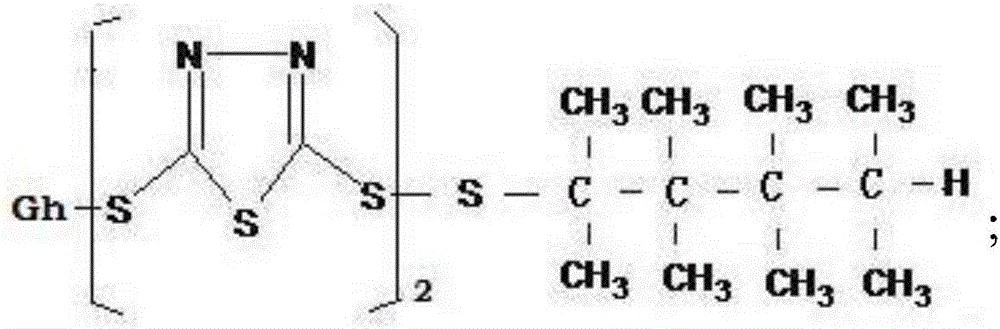

[0112] (1) Synthesis of alkylthio compounds of oil-soluble thiadiazole dimers

[0113] a, add 1mol DMTD dimer, 400ml ethanol, 400ml deionized water, 1ml KH560, 1ml polyethylene glycol ether and tributylamine mixture (weight ratio is 1: 1) Mix, stir and dissolve for 30 minutes, and cool down the mixed solution to 0°C;

[0114] b. Add 32wt% NaOH solution dropwise to the mixed solution in step a through a high-position funnel, and finish adding dropwise within 2-5 hours, keep stirring and control the dropping speed, and control the temperature of the mixed solution not to exceed 20°C, and use an online pH meter When the pH value of the detection solution is 6.5-7.5, the reaction reaches the end point, and the mixed solution is light yellow, clear and transparent liquid;

[0115] c. Add 1.0-1.5mol tert-nonylmerc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com