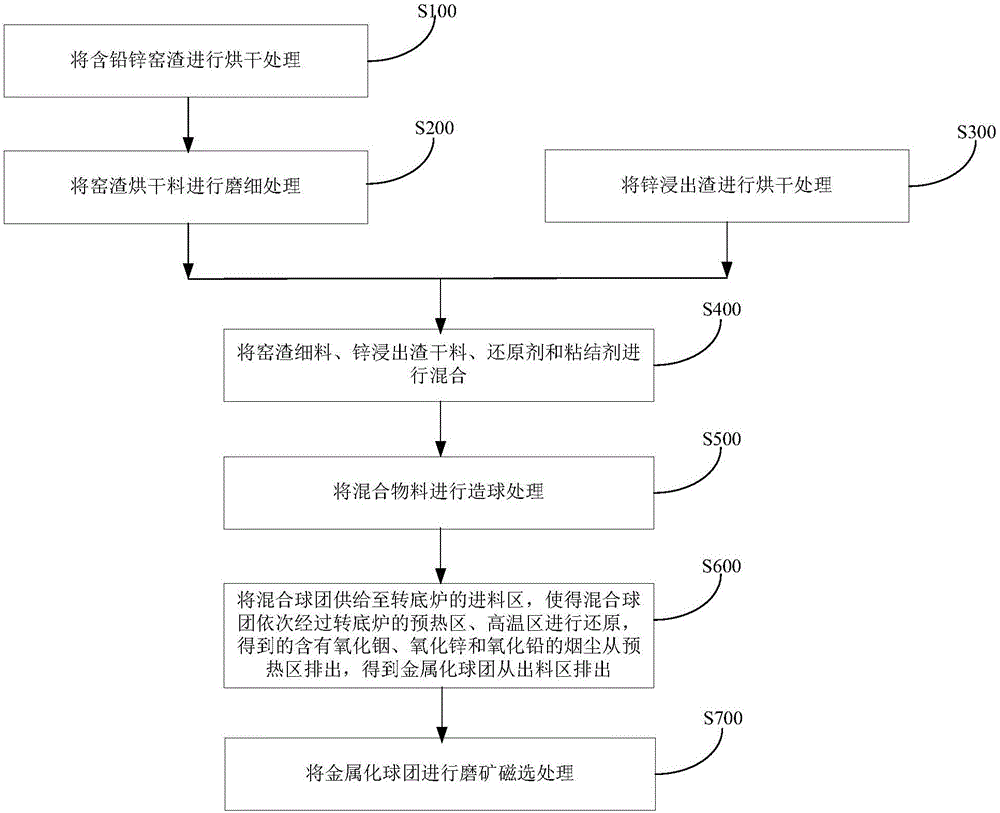

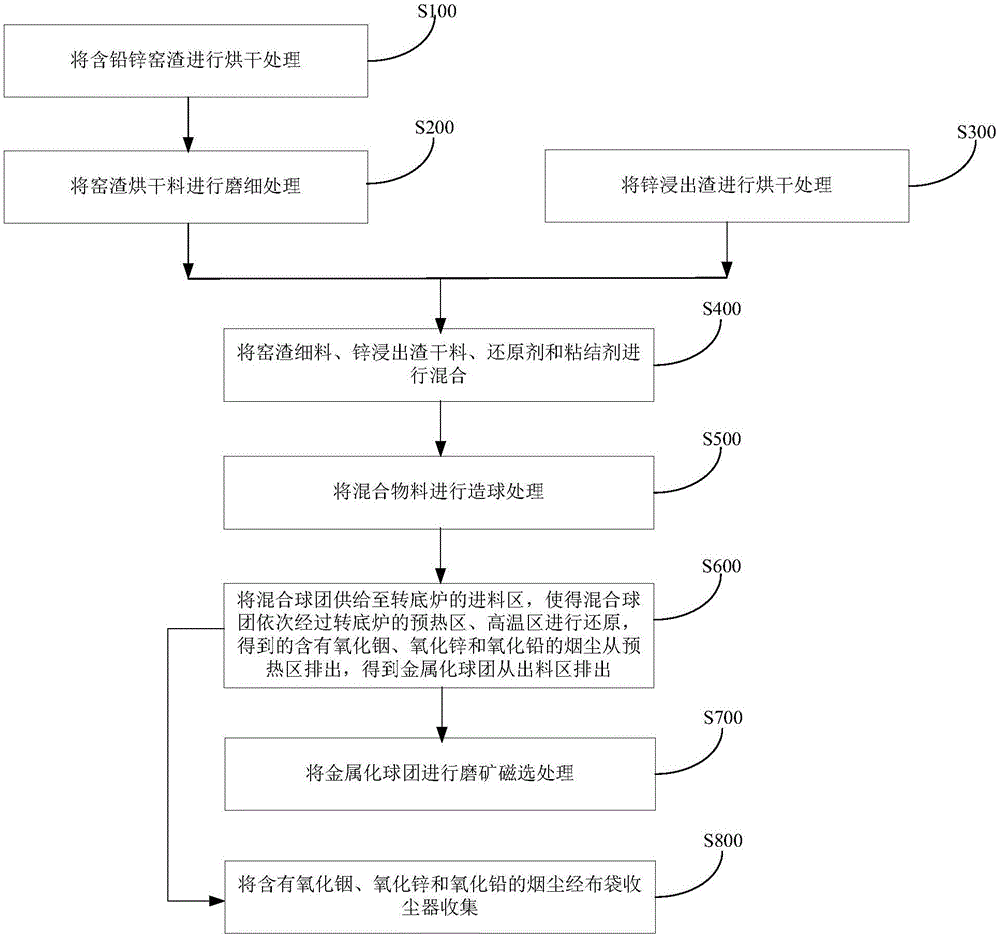

Method and system for treating lead and zinc waste materials

A waste, lead-zinc technology, applied in the field of metallurgy, can solve problems such as high mineral dispersion, unsmooth production, and material reflow, and achieve the effects of reducing reduction temperature, reducing processing costs, and reducing external allocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

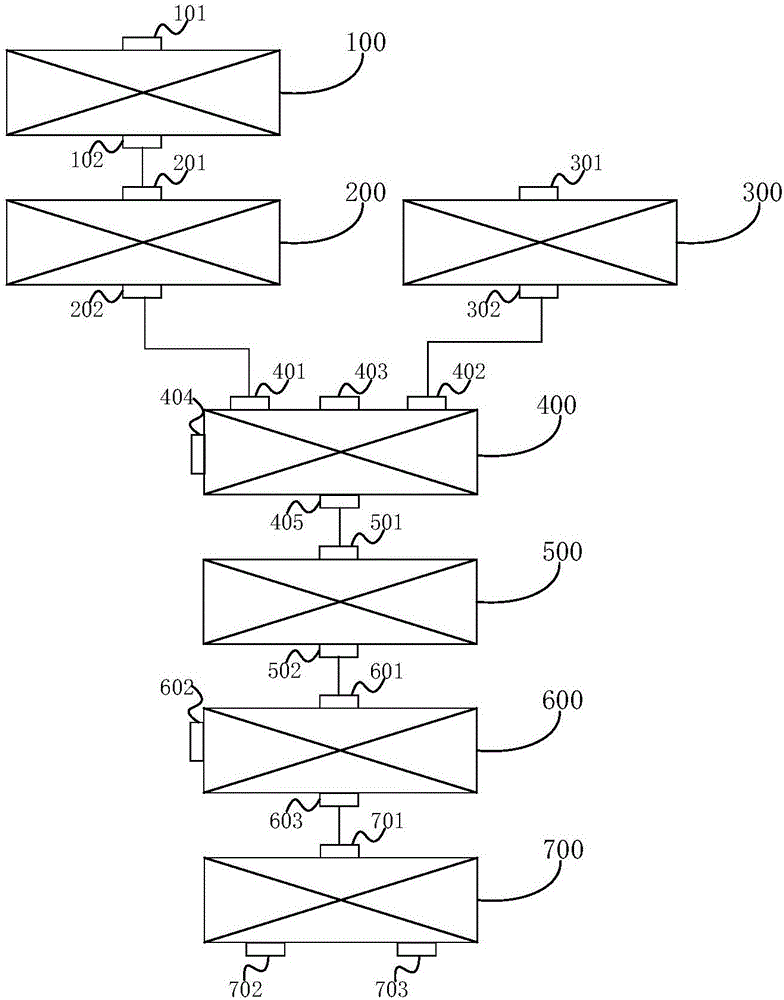

Method used

Image

Examples

Embodiment 1

[0088] The iron content in the lead-containing zinc kiln slag is 28wt%, the MFe content is 12wt%, the C content is 15wt%, and the Zn content is 1.5wt%. The zinc content in the zinc leaching slag is 16wt%, and the iron content is 22wt%. t. Dry the kiln slag until the water content does not exceed 4wt%, then crush and grind the obtained kiln slag to a particle size of 30 μm, accounting for 95%, and dry the zinc leaching slag until the water content is lower than 5wt%, and the obtained kiln The slag fines and zinc leached slag dry material are mixed with bentonite, wherein, based on 100 parts of kiln slag fine material, mixed with 42 parts of zinc leached slag dry material, 3 parts of bentonite, and mixed and ground in the moistening equipment , and then adjust the water content of the obtained mixture and send it to the roller briquetting machine to obtain mixed pellets, and dry the pellets until the moisture content is <2%, and then send them to the rotary hearth furnace for re...

Embodiment 2

[0090] The iron content in the lead-containing zinc kiln slag is 28wt%, the MFe content is 12wt%, the C content is 15wt%, and the Zn content is 1.5wt%. The zinc content in the zinc leaching slag is 16wt%, and the iron content is 22wt%. t. Dry the kiln slag until the water content does not exceed 5wt%, then crush and grind the obtained kiln slag to a particle size of 30 μm and account for 95%, dry the zinc leaching slag until the water content is lower than 5wt%, and then the obtained kiln The slag fines and zinc leaching slag dry material are mixed with anthracite and bentonite, wherein, based on 100 parts of kiln slag fine material, 42 parts of zinc leaching slag dry material are mixed, 6 parts of reducing agent are added, and 3 parts of bentonite are added. Mix and grind in the grinding equipment, then adjust the moisture content of the obtained mixture and send it to the double-roller briquetting machine to obtain mixed pellets, and dry the pellets until the moisture conten...

Embodiment 3

[0092] The iron content in the lead-containing zinc kiln slag is 28wt%, the MFe content is 12wt%, the C content is 15wt%, and the Zn content is 1.5wt%. The zinc content in the zinc leaching slag is 16wt%, and the iron content is 22wt%. t. Dry the kiln slag until the water content does not exceed 3wt%, then crush and grind the obtained kiln slag to a particle size of 30 μm and account for 95%, dry the zinc leaching slag until the water content is lower than 3wt%, and then the obtained kiln The slag fines and zinc leaching slag dry material are mixed with bentonite, wherein, based on 100 parts of kiln slag fine material, 25 parts of zinc leaching slag dry material are mixed, 3 parts of bentonite are added, and they are mixed and ground in the moistening equipment , and then adjust the water content of the obtained mixture and send it to the double-roller briquetting machine to obtain mixed pellets, and dry the pellets until the moisture content is <2%, and then send them to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com