Method for generating dozens of megampere pulse currents and z-pinch direct drive source

A technology of pulse current and generation method, applied in circuits, electrical components, transformers, etc., can solve problems such as low voltage utilization, poor maintainability, and poor reliability, and achieve the effects of reducing current loss, reducing impact, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

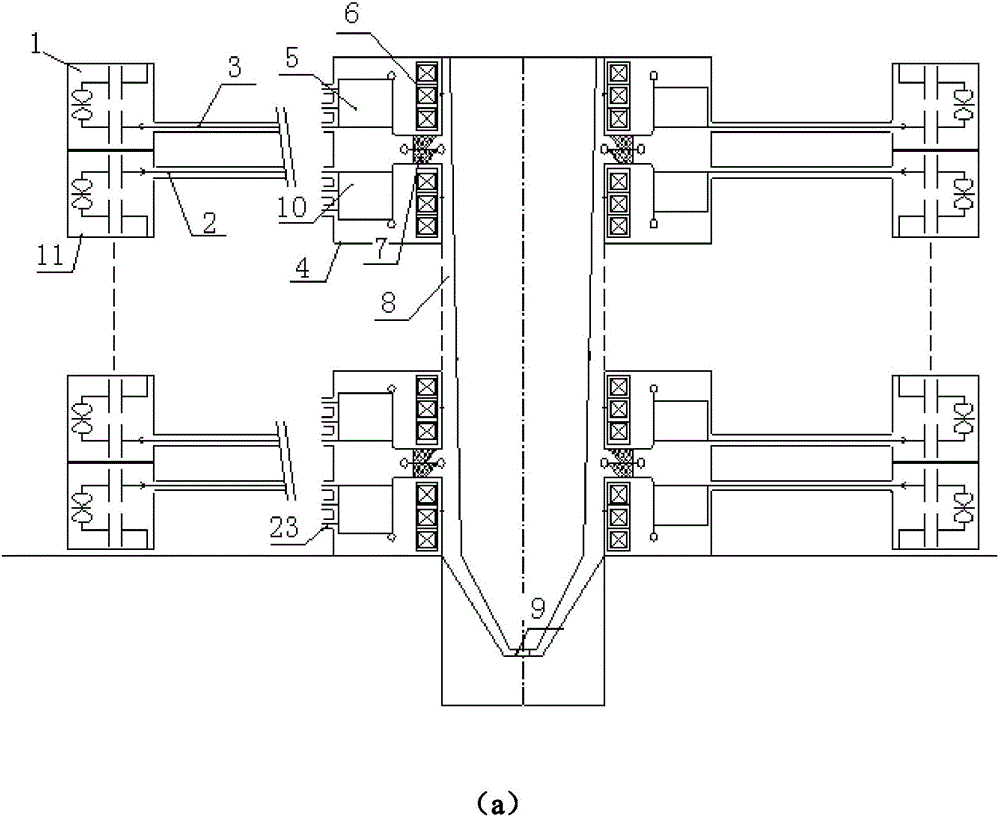

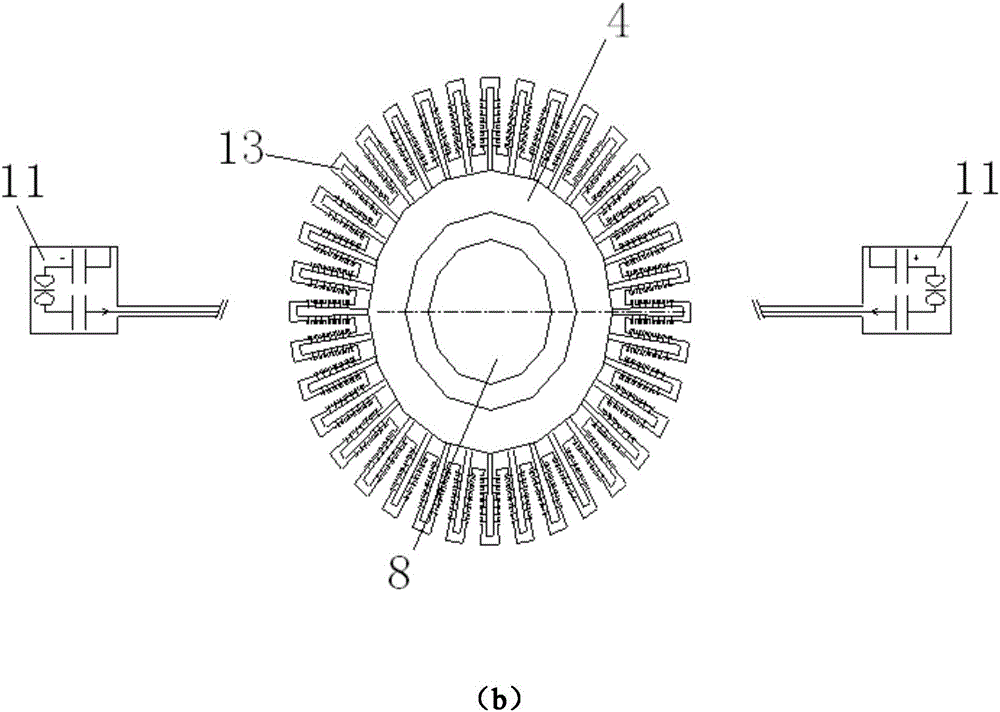

[0049] 1) Pulse power source structure

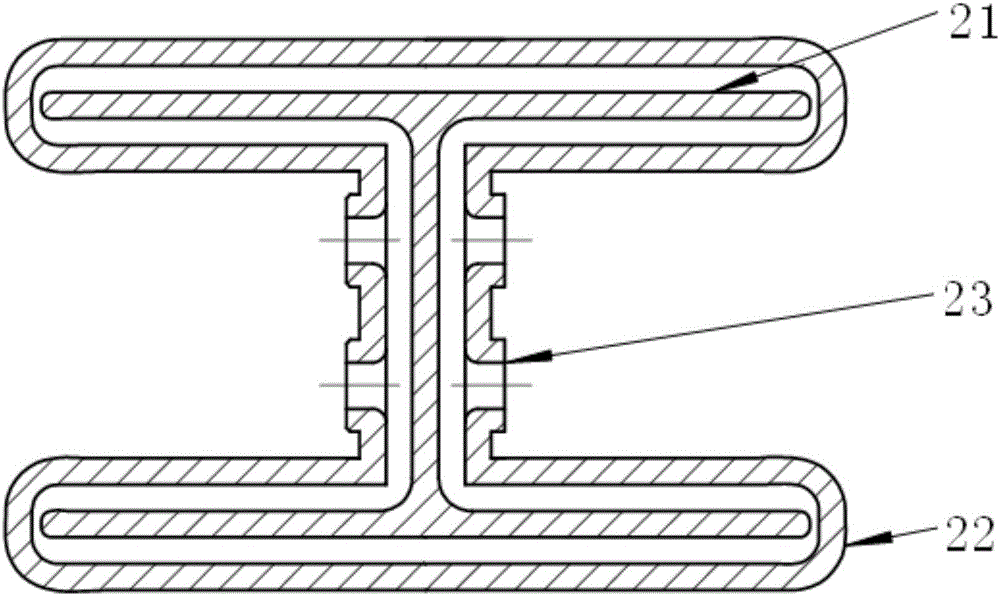

[0050] The primary discharge branch adopts Marx with 2-stage positive and negative polarity charging, 4 plastic case capacitors with a capacity of 80nF double-ended outlets and a working voltage of 100kV, and 2 low-inductance gas switches. The equivalent inductance of the primary discharge branch is 480nH, equivalent The series capacitance is 20nF, and the equivalent series resistance is 0.6Ω. The matching impedance of the above discharge branch is 5.9Ω, and the nominal energy storage is 1.6kJ. When the capacitor is charged at 100kV, each primary discharge branch can provide a 220kV / 37.3kA electric pulse to the matching load. The electrical pulse is transmitted to the I-shaped three-plate transmission line around the induction cavity through an impedance-matched (5.9 hp) high-voltage cable.

[0051] 72 I-shaped three-plate transmission lines are evenly arranged in the upper and lower layers around the induction cavity of each level, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com