Preparation method of human milk fat substitute

A technology for replacing fat and lipase, which is applied in the field of human milk replacement fat preparation, and can solve the problems of increasing deacidification cost, OPO content and influence on purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

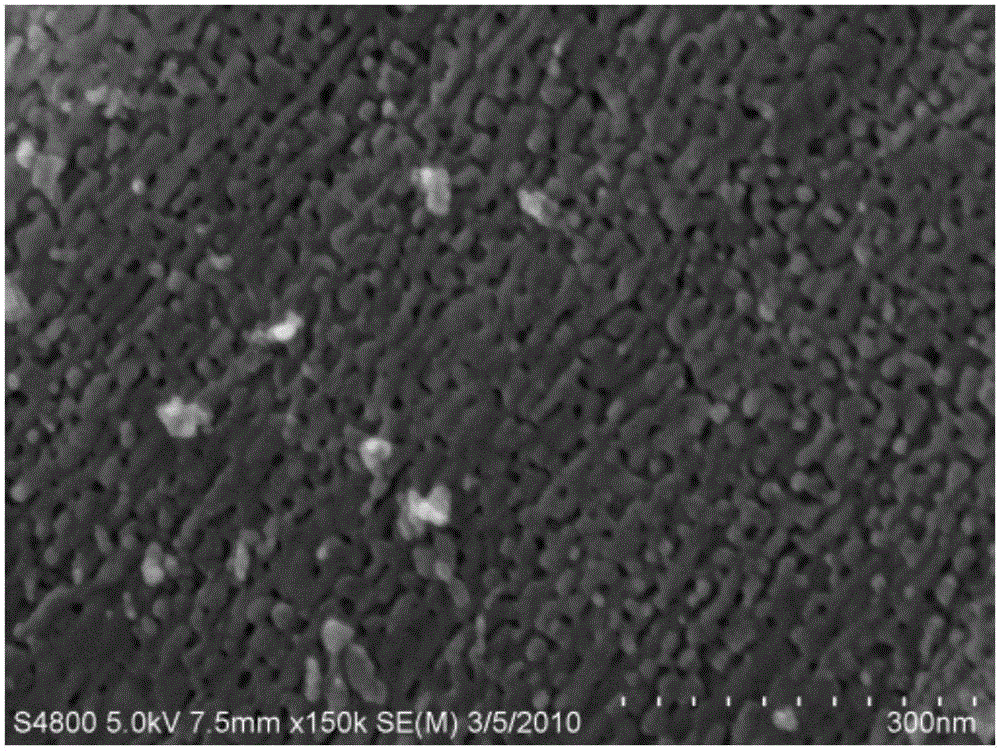

[0038] Wash titanium dioxide with water, the electron microscope picture of titanium dioxide is as follows figure 1 As shown, an ordered porous structure can be observed at a resolution of 300 nm, which can provide sites for enzyme protein loading. The mesoporous titanium dioxide material was pre-treated in an oven at 120°C for 12 hours, and 1g of the treated TiO was taken 2 Granules, add dichloromethane with a mass-volume ratio of 1:10, then add 1-aminobutylphosphonic acid with a mass ratio of 3:1, stir at room temperature for 24 hours, filter with suction, and wash with acetone aqueous solution (volume ratio 1:1) , dried in an oven at 100°C for 8h. Obtained TiO 2 The material is recorded as 1-aminobutylphosphonic acid—TiO 2 .

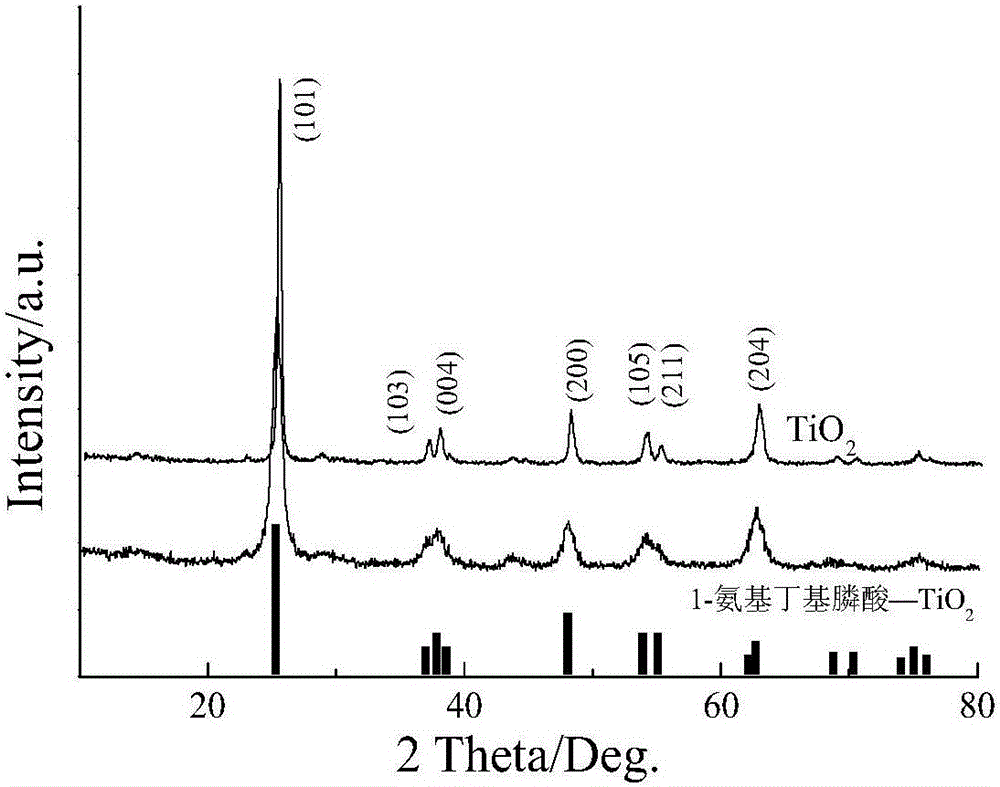

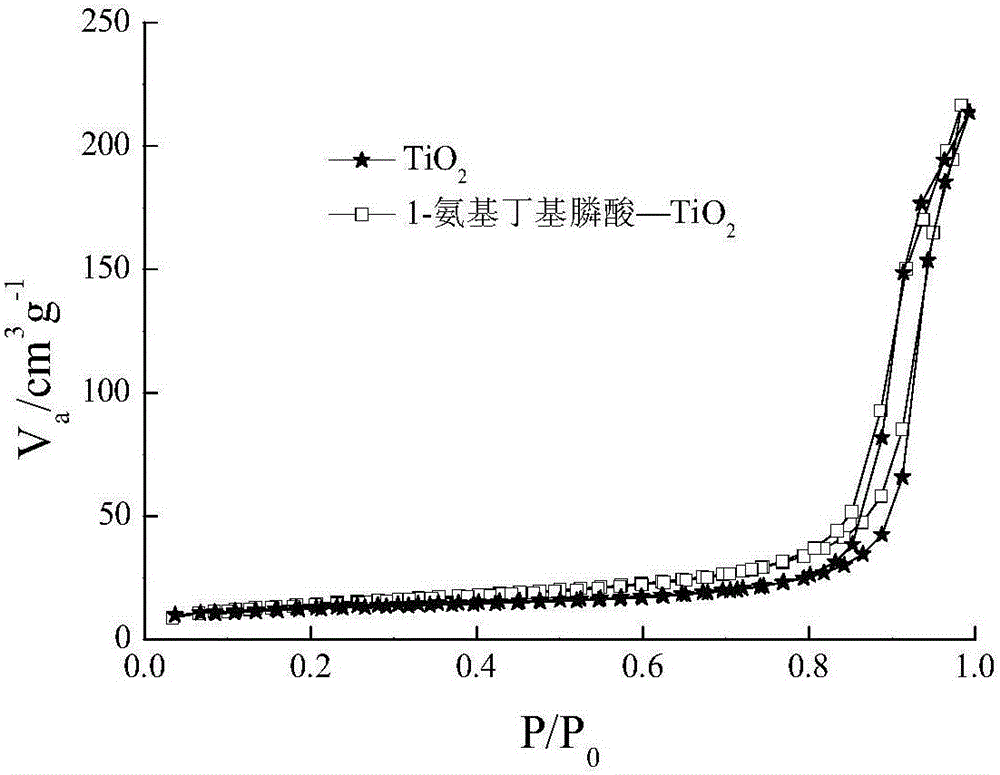

[0039] like figure 2 As shown, the mesoporous TiO before modification 2 The particles have five obvious diffraction peaks at 2θ=25.3, 37.8, 48.1, 53.9 and 55.1, corresponding to (101), (004), (200), (105) and (211) crystals of anatase crystal f...

Embodiment 2

[0042] Take 1.25ml of Novozymes Cheese Flavor Lipase 20000L, dilute to 25ml with pH=7 phosphate buffer, take two 50ml centrifuge tubes, add 10ml of diluted enzyme solution, 0.1g of pure titanium dioxide and 1-aminobutylphosphonic acid respectively The modified titanium dioxide was oscillated overnight in a constant temperature oscillating reactor at 250r / min and 25°C. Then the centrifuge tube was centrifuged for 10 min at 8000 r / min. Finally, the supernatant was removed, and the product was dried in an oven at 60° C. to obtain the immobilized enzyme.

[0043] Figure 5 TiO 2 and 1-aminobutylphosphonic acid—TiO 2 Comparison chart of activity and specific activity of immobilized cheese essence lipase. The cheese essence lipase used in the experiment is derived from Aspergillus oryzae (Aspergillus oryzae), and is produced by submerged fermentation of genetically modified microorganisms. The enzyme protein itself is not genetically modified, but is isolated and purified from ...

Embodiment 3

[0045] Take 0.1g of Rhizopus oryzae lipase, adjust the volume to 100ml with pH=7 phosphate buffer, take two 50ml centrifuge tubes, add 10ml of diluted enzyme solution and 0.1g of pure titanium dioxide and 1-aminobutyl phosphonic acid modified Titanium dioxide was shaken overnight in a constant temperature shaking reactor under the conditions of 250r / min and 25°C. Then the centrifuge tube was centrifuged for 10 min at 8000 r / min. Finally, the supernatant was removed, and the product was dried in an oven at 60° C. to obtain the immobilized enzyme.

[0046] like Image 6 shown, with TiO 2 Compared to 1-aminobutylphosphonic acid—TiO 2 The enzyme loading of immobilized Rhizopus oryzae lipase decreased, and the unmodified TiO 2 The loading capacity is 8.3mg / g, and after modification, 1-aminobutylphosphonic acid—TiO 2 The loading amount is 6.51mg / g, the specific activity of the immobilized enzyme is calculated according to the enzyme activity and the enzyme loading amount, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com