Method for preparing porous hollow activated carbon microspheres by natural sporopollen self-template method

A technology of activated carbon microspheres and self-templates, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of equipment corrosive environment, complex process, high cost, and achieve simple process, cheap and easy-to-obtain carbon source, and electrical conductivity. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

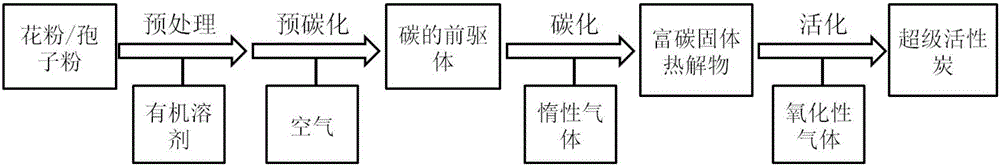

[0030] Such as figure 1 Shown, the present invention provides a kind of method that natural sporopollen prepares porous hollow activated carbon microspheres from template method, and this preparation method comprises the following steps:

[0031] S1 pretreatment: Soak the pollen / spore powder in an organic solvent, the organic solvent is acetone or formaldehyde, and magnetically stir for 4-14 hours;

[0032] S2 suction filter to filter the stirred liquid, clean it according to the cleaning sequence of alcohol first, then deionized water, and then dry;

[0033] S3 pre-carbonization: the pretreated pollen / spore powder is moved to the muffle furnace, raised to 275-300°C at a heating rate of 1-3°C / min, and pre-carbonized for 4-8 hours in an air atmosphere;

[0034] The drying in step S2 can be combined with step S3, and the temperature is raised in stages in the same muffle furnace, and then the temperature is raised and then the heat is kept;

[0035] S4 carbonization: the black...

Embodiment 1

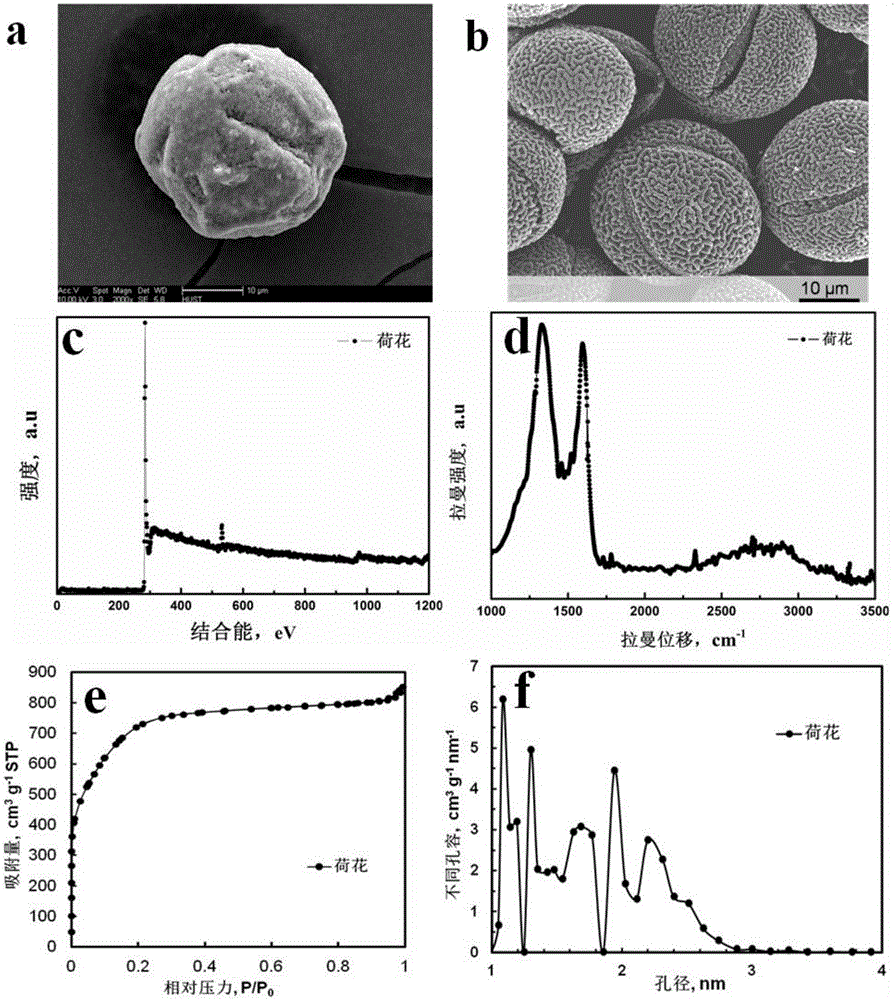

[0039] Take 50g of a certain brand of edible lotus pollen purchased online, put it in 200ml of analytically pure acetone solution, stir it magnetically at 300r / min for 6h, wash (alcohol, deionized water), and dry at 80°C for 12h. Then pre-carbonize in a muffle furnace at 300°C (heating rate 1°C / min) for 6h, and then in a tube furnace at 700°C (heating rate 10°C / min) under the protection of argon with a gas flow rate of 250mL / min. Pyrolysis and carbonization for 2 hours, and finally activation for 6 hours in a carbon dioxide atmosphere at 900°C (heating rate: 10°C / min) and an air flow of 250mL / min. Super activated carbon was obtained after drying at 120°C.

[0040] figure 2 (a) is a scanning electron microscope (SEM) image of lotus pollen before treatment, figure 2 (b) is the SEM image of lotus super activated carbon after treatment. It can be seen that this process does not destroy the microstructure of the original lotus pollen, and it is still a porous hollow microsphere...

Embodiment 2

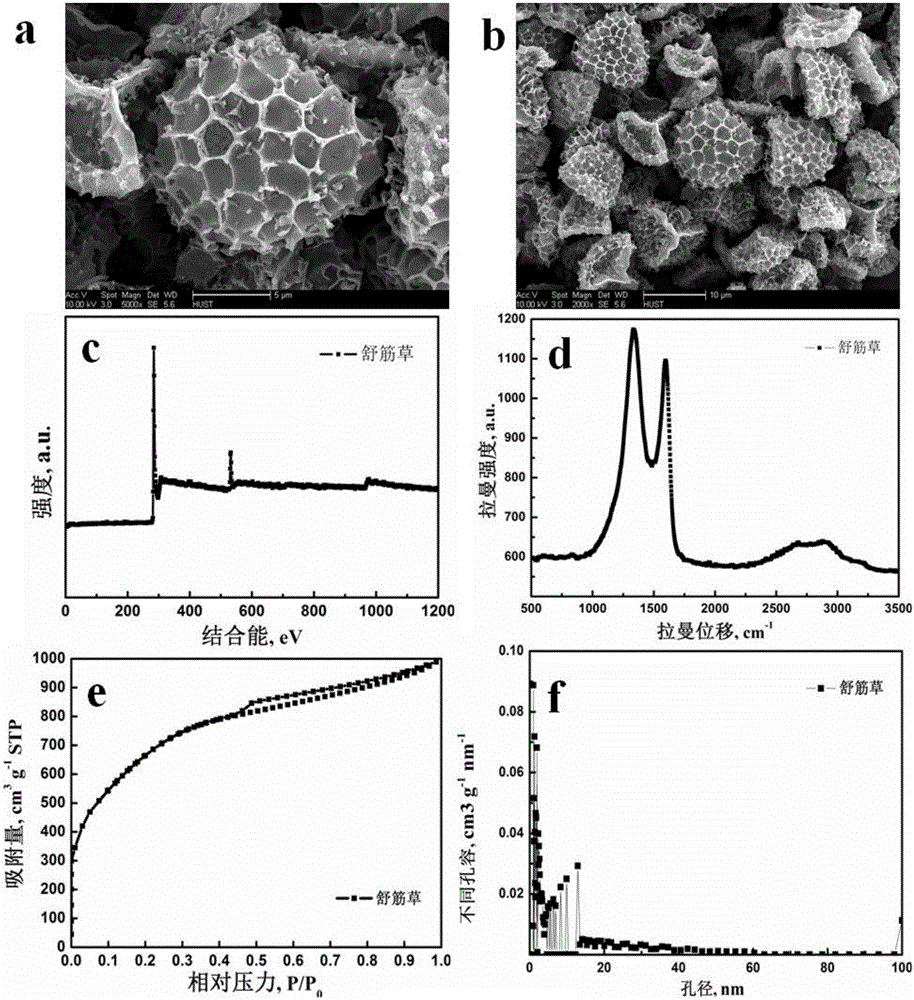

[0042] Dissolve 10 g of the spore powder collected outdoors in 50 ml of analytically pure formaldehyde solvent, stir magnetically at 200 r / min for 4 h, wash (alcohol, deionized water), and dry at 70 ° C for 10 h. After that, it was pre-carbonized in a muffle furnace at 275°C (heating rate of 2°C / min) for 4h, and then in a tube furnace at 700°C (heating rate of 20°C / min) under the protection of argon with an air flow rate of 250mL / min. Pyrolysis and carbonization for 3 hours, and finally activation for 5 hours in a carbon dioxide atmosphere at 900°C (heating rate: 20°C / min) and an air flow of 200mL / min. Super activated carbon was prepared after drying at 100°C.

[0043] image 3 (a) is the SEM figure before the treatment of the spore powder of Shujincao spores, image 3 (b) is the SEM picture of the processed Shujincao activated carbon. It can be seen that the process conditions did not destroy the microstructure of the raw material, and the tetrahedral structure with footbal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com