Ytterbium aluminum phosphorus fluorine doped silica optical fiber preform core rod and preparation method thereof

A silica fiber and fluorine-doped technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of non-linear effects, unfavorable control of the longitudinal consistency of the refractive index of the prefabricated core rod, and different sediment components, etc., to achieve Realize the effect of laser output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

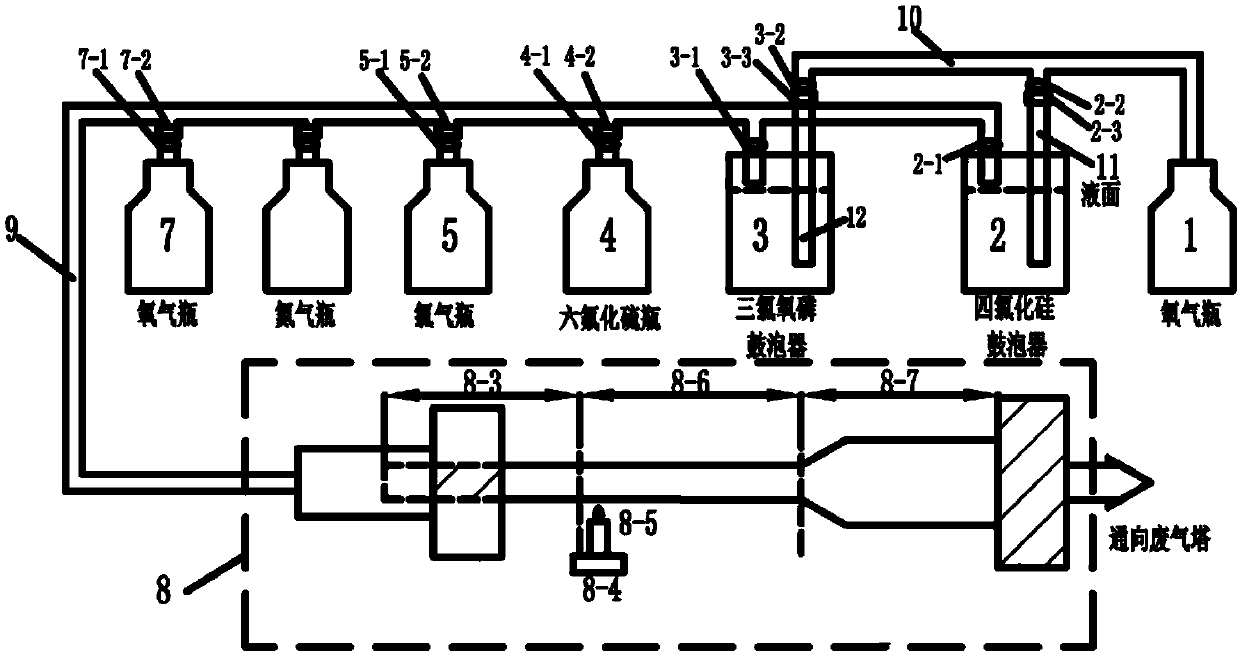

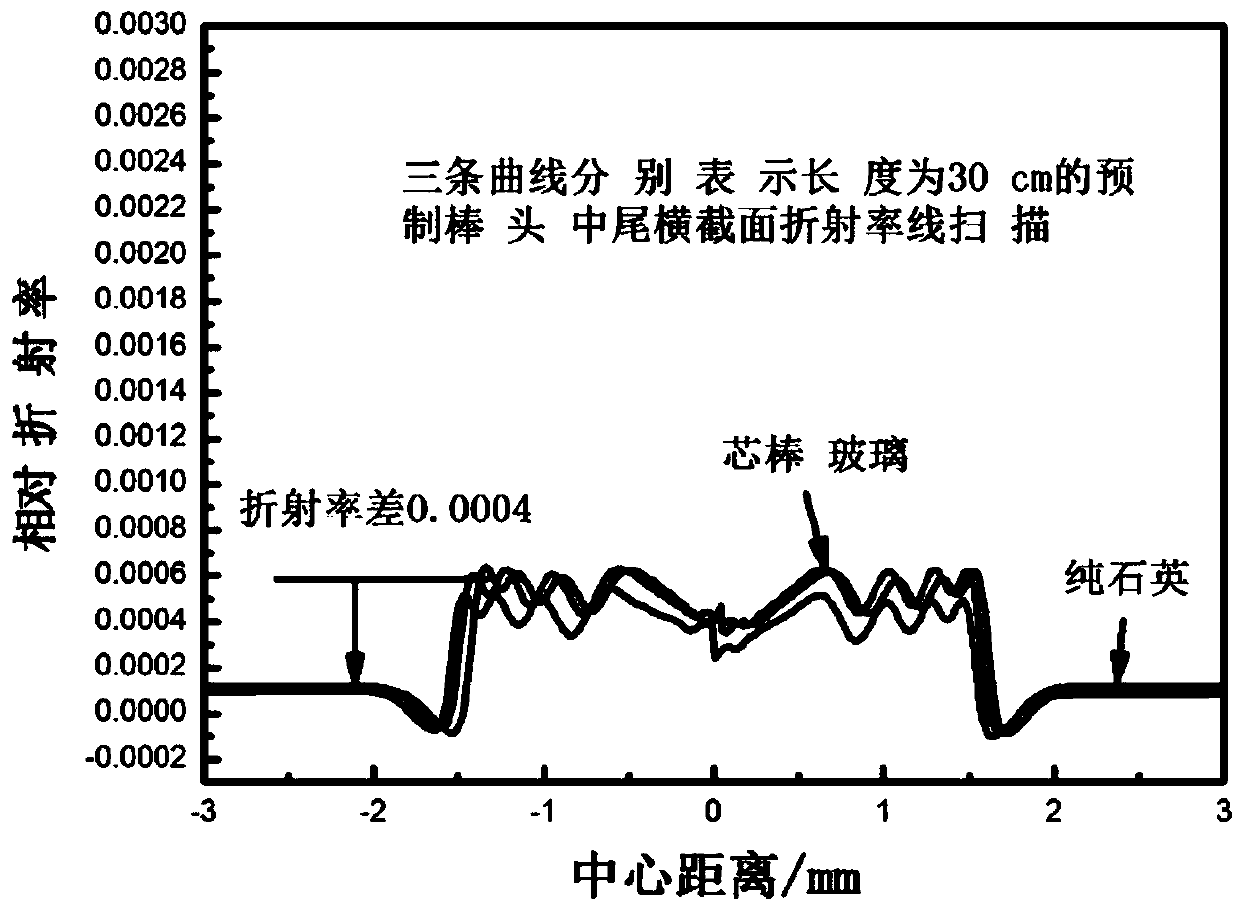

[0042] The average refractive index of the ytterbium-aluminum-phosphorus-fluorine-doped silica optical fiber preform core rod is higher than that of pure silica, and the difference is 0.0004. The core rod glass composition: 0.15Yb 2 O 3 ·1.21Al 2 O 3 ·1.22P 2 O 5 ·0.16F·97.26SiO 2 . In this embodiment, the ytterbium aluminum phosphorus fluoride doped silica optical fiber preform core rod adopts an improved chemical vapor deposition system (see figure 1 ) Combined with solution immersion method for preparation. The method includes the following steps:

[0043] 1) Preparation: Take a 600mm quartz tube as the deposition tube 8-6, wash and dry the deposition tube 8-6, and weld one end of the deposition tube 8-6 to the front tube 8-3 of the lathe 8 , The other end is welded to the exhaust pipe 8-7 of the lathe 8; configuration solution: add a certain amount of aluminum chloride and ytterbium chloride to ethanol to dissolve, the concentration of ytterbium chloride in the solution is 0....

Embodiment 2

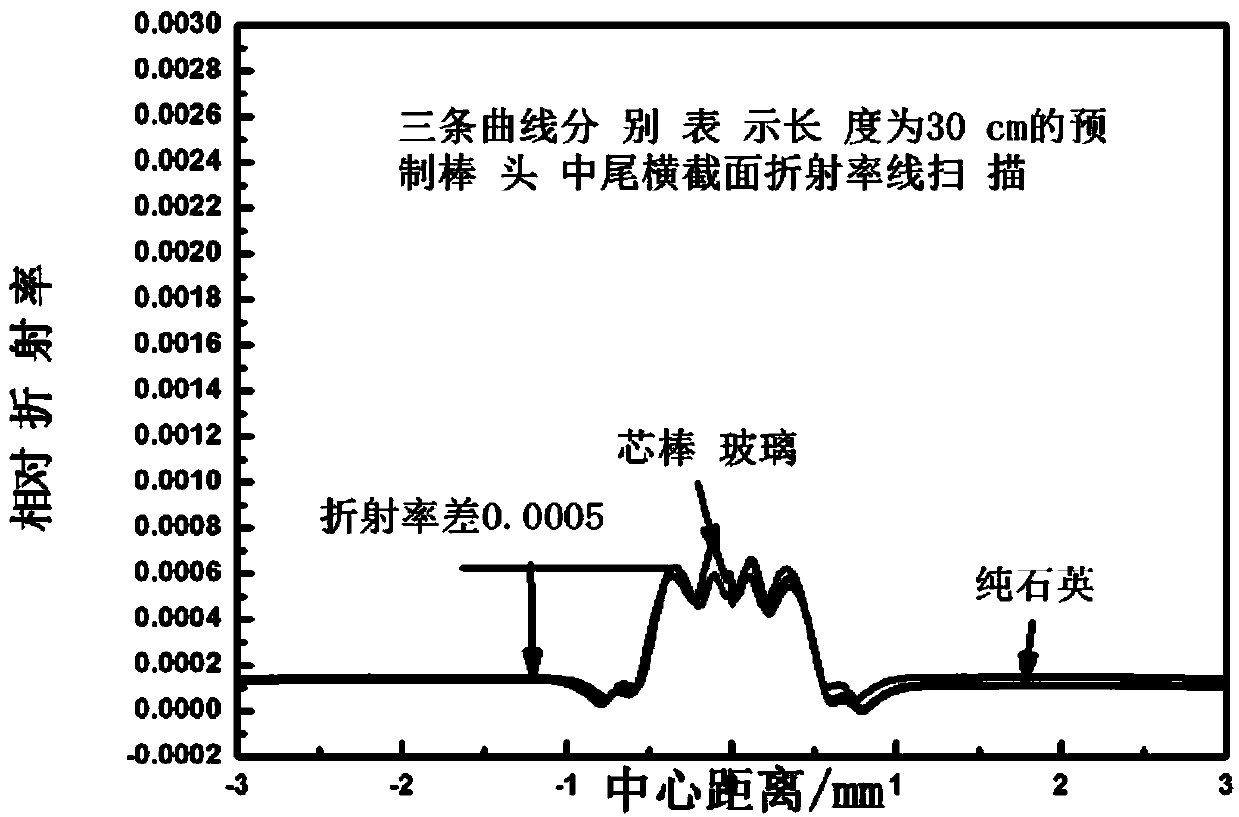

[0051] Example 2: The average refractive index of the ytterbium-aluminum-phosphorus-fluoride-doped silica optical fiber preform core rod is 0.0005 higher than that of pure silica, and the core rod glass composition: 0.2Yb 2 O 3 · 2.12Al 2 O 3 ·2.23P 2 O 5 ·0.36F·95.09SiO 2 In this embodiment, the ytterbium aluminum phosphorus fluoride doped silica optical fiber preform core rod adopts an improved chemical vapor deposition system (see figure 1 ) Combined with solution immersion method for preparation. The method includes the following steps:

[0052] 1) Preparation: Take a 800mm quartz tube as the deposition tube 8-6, wash and dry the deposition tube 8-6, and weld one end of the deposition tube 8-6 to the front tube 8-3 of the lathe 8 , The other end is welded to the exhaust pipe 8-7 of the lathe 8; configuration solution: add a certain amount of aluminum chloride and ytterbium chloride to ethanol to dissolve, the concentration of ytterbium chloride in the solution is 0.025mol / L, y...

Embodiment 3

[0060] Embodiment 3: The average refractive index of the ytterbium-aluminum-phosphorus-fluoride-doped silica optical fiber preform core rod is 0.0008 higher than that of pure silica, and the core rod glass composition: 0.25Yb 2 O 3 · 2.82Al 2 O 3 ·2.73P 2 O 5 ·1.11F·93.09SiO 2 In this embodiment, the ytterbium aluminum phosphorus fluoride doped silica optical fiber preform core rod adopts an improved chemical vapor deposition system (see figure 1 ) Combined with solution immersion method for preparation. The method includes the following steps:

[0061] 1) Preparation: Take a quartz tube with a length of 1000mm as the deposition tube 8-6, wash and dry the deposition tube 8-6, and weld one end of the deposition tube 8-6 to the front tube 8-3 of the lathe 8 , The other end is welded to the exhaust pipe 8-7 of the lathe 8; configuration solution: add a certain amount of aluminum chloride and ytterbium chloride to ethanol to dissolve, the concentration of ytterbium chloride in the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Beam quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com