Negative oxygen ion functional coating, as well as preparation method and application

A negative oxygen ion and functional technology, applied in the coating field of expanded perlite external wall insulation board, can solve the problems of improving air quality, etc., achieve the effect of simple painting process, simple preparation process, and improved decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

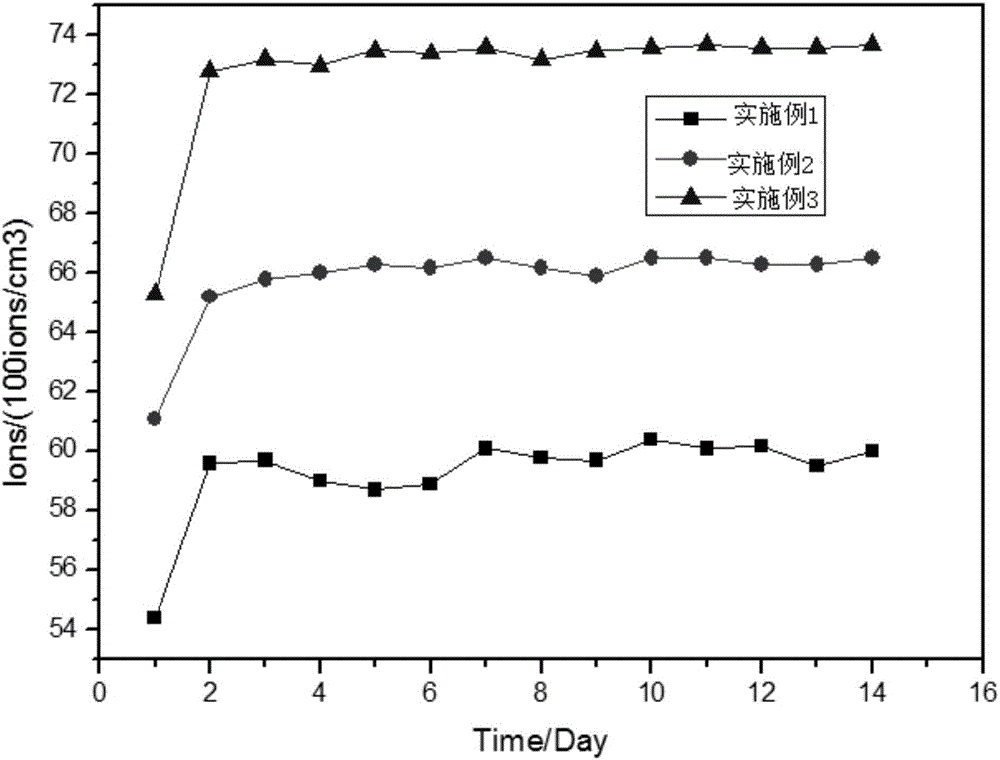

Embodiment 1

[0021] The preparation method of the expanded perlite outer wall insulation board with negative oxygen ion functional coating in this embodiment is as follows:

[0022] (1) Get 3 parts of tourmaline powder, 1 part of graphene oxide, 1 part of nano-titanium oxide, 15 parts of gypsum powder, 30 parts of diatomaceous earth, mix evenly to obtain powder;

[0023] (2) Dissolve 10 parts of styrene-acrylic emulsion in 20 parts of water. After it is completely dissolved, add the above-mentioned mixed powder and stir at 8000 rpm to make a water-based paint;

[0024] (3) Paint the water-based paint on the outer surface of the expanded perlite insulation board for 3 times, and then obtain the expanded perlite outer wall insulation board with negative oxygen ion functional coating through natural curing.

Embodiment 2

[0026] The preparation method of the expanded perlite outer wall insulation board with negative oxygen ion functional coating in this embodiment is as follows:

[0027] (1) Get 4 parts of tourmaline powder, 2 parts of graphene oxide, 2 parts of nano-titanium oxide, 17 parts of gypsum powder, 20 parts of diatomaceous earth, 15 parts of montmorillonite, and mix uniformly to obtain powder;

[0028] (2) Dissolve 15 parts of styrene-acrylic emulsion in 35 parts of water, after completely dissolving, add the above mixed powder and stir at 7000 rpm to make water-based paint;

[0029] (3) Brush the water-based paint 4 times on the outer surface of the expanded perlite insulation board, and then obtain the expanded perlite outer wall insulation board with a negative oxygen ion functional coating through natural maintenance.

[0030] Other implementations are the same as in Example 1.

Embodiment 3

[0032] The preparation method of the expanded perlite outer wall insulation board with negative oxygen ion functional coating in this embodiment is as follows:

[0033] Benzene, water-based paint is made by adding water, which can be obtained by natural curing after painting on the outer surface of the expanded perlite insulation board.

[0034] (1) Get 5 parts of tourmaline powder, 3 parts of graphene oxide, 3 parts of nano-titanium oxide, 20 parts of gypsum powder, 30 parts of diatomaceous earth, 10 parts of montmorillonite, and mix uniformly to obtain powder;

[0035] (2) Take 15 parts of acrylic emulsion, 5 parts of styrene-acrylic emulsion, and 5 parts of water-based polyurethane, dissolve them in 55 parts of water, and after completely dissolving, add the above-mentioned mixed powder and stir at 8000 rpm to make a water-based paint;

[0036] (3) Brush the water-based paint 5 times on the outer surface of the expanded perlite insulation board, and then obtain the expanded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com