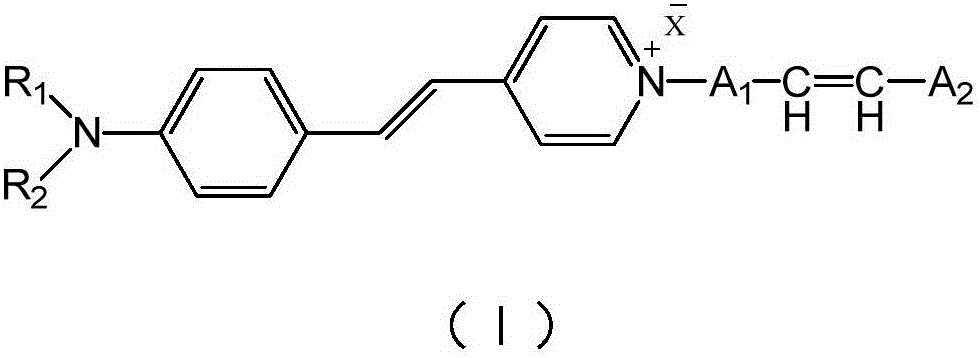

Aminostyrylpyridinium-salt fluorescent monomer and preparing and application of polymer of aminostyrylpyridinium-salt fluorescent monomer

A technology of styrene pyridinium salt and fluorescent monomer, which is applied in the fields of fluorescence/phosphorescence, luminescent materials, and material analysis through optical means, and can solve problems such as poor practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]

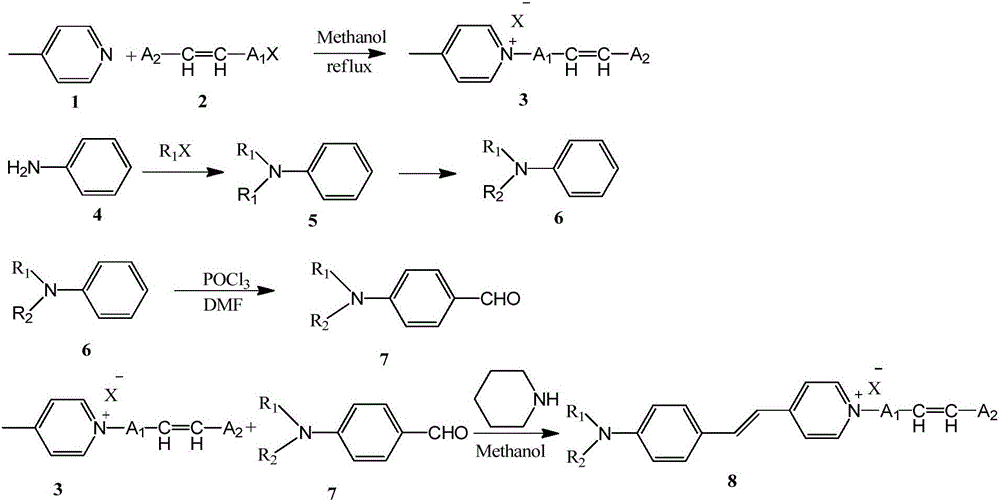

[0043] synthetic route:

[0044]

[0045] 1) Dissolve 9.3g (0.1mol) of 4-methylpyridine in 50mL of anhydrous methanol, add 8.46mL (0.1mol) of propylene bromide at room temperature, heat to reflux overnight, remove the solvent and use ethyl acetate and methanol The mixed solvent was used as the mobile phase, and purified by column chromatography to obtain the pure product of compound 3.

[0046] 2) Use 100 mL of N,N-dimethylformamide (DMF) / N-methylpyrrolidone (NMP) with a volume ratio of 9:1 as solvent, 19 mL (200 mmol) of aniline, and 65 mL (600 mmol) of 1-bromobutane , Na2CO3 84g (800mmol) was reacted at 120°C for 24h. Cool to room temperature, and filter to remove insoluble matter. The precipitate was washed with ethyl acetate. The filtrate was spin-dried, then water was added and the aqueous phase was extracted with ethyl acetate. Pass through the column with n-hexane as the mobile phase to obtain a light yellow liquid product, which is Compound 5. Yield...

Embodiment 2

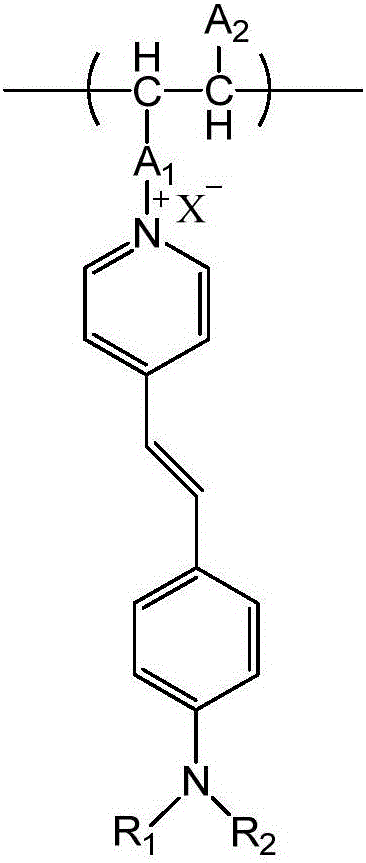

[0049] Embodiment 2 Preparation of water-soluble fluorescent tracer polymer

[0050] The reaction formula is as follows:

[0051]

[0052]Weigh 5.4g of acrylamide and 3.6g of acrylic acid to make an aqueous solution, adjust the pH value to about 7 with NaOH solution, then add the solution to a three-necked reaction flask placed in a constant temperature water bath and equipped with an electromagnetic stirrer, and then add 1.5g of SDS Stir, dissolve with SDS, add 50mg of fluorescent monomer, heat up to 50°C, continue stirring to fully dissolve the fluorescent monomer in the micelles of the surfactant, after a transparent solution is formed, pass N2 to deoxygenate, add 9.83mg of sulfurous acid Sodium hydrogen and 21.55mg ammonium persulfate reacted for 8h. The reactants were fully cut into pieces, washed with ethanol, and finally dried at 50°C to obtain a water-soluble fluorescent polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com