Polyurethane all-water-based organic foaming material and preparation method thereof

A foaming material, all water-based technology, applied in the field of organic polymer compound preparation, can solve problems such as low surface activity, no flame retardant effect, ozone layer destruction price, etc., achieve uniform foam internal structure, reduce toxic smoke generation, Effect of reducing heat release

Inactive Publication Date: 2016-11-16

重庆钱珑新科技有限公司

View PDF7 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Foaming agents commonly used in the production of polyurethane foams include Freon foaming agents, alkane foaming agents, and HCFC foaming agents. The disadvantages of these foaming agents are: (1) Freon has an ozone-destroying effect. With the enhancement of environmental protection awareness, Freon has been gradually eliminated as a blowing agent; (2) alkane blowing agents (mainly positive, iso, cyclopentane, etc.) (3) HCFC blowing agent, this type of substitute also has the problem of ozone depletion and is expensive

[0005] The disadvantages of the above-mentioned technical solution are: 1. CO will be produced during full water foaming. The molecular weight of CO gas is equivalent to that of air, but the molecule is small, and it is easy to escape through the cell wall of rigid polyurethane foam, causing the internal pressure of the cell to decrease, and the air The molecules are larger, and the speed of infiltration into the cells is slower, causing the CO2 to diffuse outward from the cells faster than the speed of air entering the foam cells, resulting in shrinkage of the polyurethane foam material and poor dimensional stability; ②The CO2 produced during full water foaming will Part of it is in the foam pores of polyurethane semi-rigid foam, while the thermal conductivity of CO2 is as high as 16.3Mw / m.K, while the thermal conductivity of air is 27mWm.K. The thermal conductivity of air is higher than that of CO2, and the thermal conductivity of polyurethane foam The thermal insulation performance is poor; 3. the existing foam stabilizer (i.e. the surfactant in the formula) has higher polarity and lower surface activity, and the final foam formed is larger, and the closed cell rate of the foam cells is lower, which further greatly reduces the heat insulation of polyurethane foam materials; ④ no flame retardant ingredients, no flame retardant effect, the current common flame retardants on the market have a high degree of hydrolysis, and will be hydrolyzed when directly used in the full water foaming process , lose the flame retardant function; ⑤ water and isocyanate react to form CO2 urea bond, and the reaction releases a lot of heat, exotherm causes the temperature of the composition to rise, when the temperature reaches 160 ° C, CO2 urea bond and excess isocyanic acid The cross-linking reaction of fat produces biuret compound, which is a rigid compound that can make the overall structure of polyurethane foam material brittle.

⑥Low-functionality polyether polyol has a solvent dilution effect (that is, higher fluidity), which can greatly reduce the viscosity of material A, but the cost of low-functionality polyether polyol is high, and it is made of low-functionality compounds The materials generally have poor hardness and dimensional stability, and it is difficult to meet customer needs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

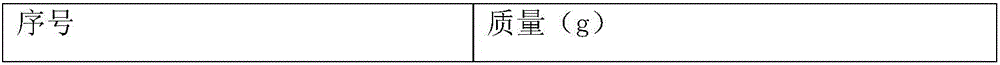

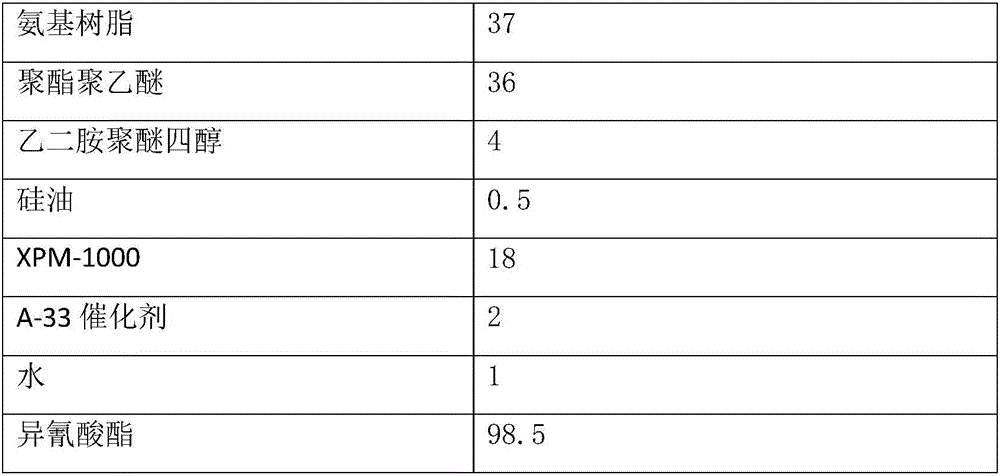

[0031] The components of the polyurethane all-water-based organic foaming material are as follows:

[0032] serial number

Embodiment 2

[0034] The components of the polyurethane all-water-based organic foaming material are as follows:

[0035] serial number

Embodiment 3

[0037] The components of the polyurethane all-water-based organic foaming material are as follows:

[0038]

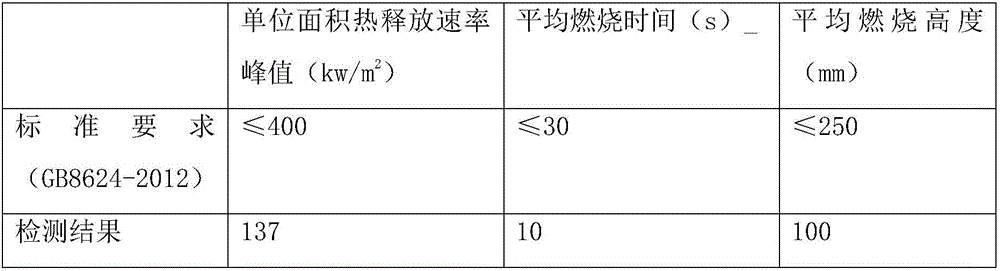

[0039]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the technical field of preparation of organic macromolecule compounds and discloses a polyurethane all-water-based organic foaming material. The polyurethane all-water-based organic foaming material is prepared from a liquid material A and a liquid material B, wherein the mass ratio of the material A to the material B is 1:(1 to 1.5); the material A is prepared from the following components in percentage by mass: 30 to 40 percent of amino resin, 35 to 40 percent of polyester polyethylether, 1 to 6 percent of high-activity crosslinking agent, 0.1 to 0.8 percent of silicone oil, 15 to 20 percent of nitrogen-phosphorus halogen-free flame retardant, 1 to 4 percent of catalyst and 1 to 3 percent of water; the material B is isocyanate. The polyurethane all-water-based organic foaming material disclosed by the invention has the advantages of strong heat insulating property, good dimensional stability, low possibility of being brittle and excellent flame-retardant effect.

Description

technical field [0001] The invention belongs to the technical field of organic polymer compound preparation. Background technique [0002] Polyurethane foam is made of polyether (or polyester polyol) and polyisocyanate as the main raw materials, plus catalyst, foam stabilizer and foaming agent, etc., after mixing and stirring to produce a chemical reaction to form a foam, according to its hardness It can be divided into two types: soft and hard. Among them, rigid polyurethane foam is often used as building materials, furniture materials, automotive interior materials, etc., and has a wide range of applications. Foaming agents commonly used in the production of polyurethane foams include Freon foaming agents, alkane foaming agents, and HCFC foaming agents. The disadvantages of these foaming agents are: (1) Freon has an ozone-destroying effect. With the enhancement of environmental protection awareness, Freon has been gradually eliminated as a blowing agent; (2) alkane blowin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G18/54C08G18/48C08G18/42C08J9/08C08G101/00

CPCC08G18/4027C08G18/4244C08G18/482C08G18/5024C08G18/544C08G2110/0083

Inventor 缪文斌罗文哲

Owner 重庆钱珑新科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com