Process for preparing ceramide by fermentation method

A technology of ceramide and fermentation method, applied in the field of preparation technology of ceramide, can solve the problems of ceramide safety doubt, ceramide safety hazard and high economic cost, and achieves the advantages of quick effect, short fermentation period and reduced economic cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Analysis of strains, preparation and identification of ceramide

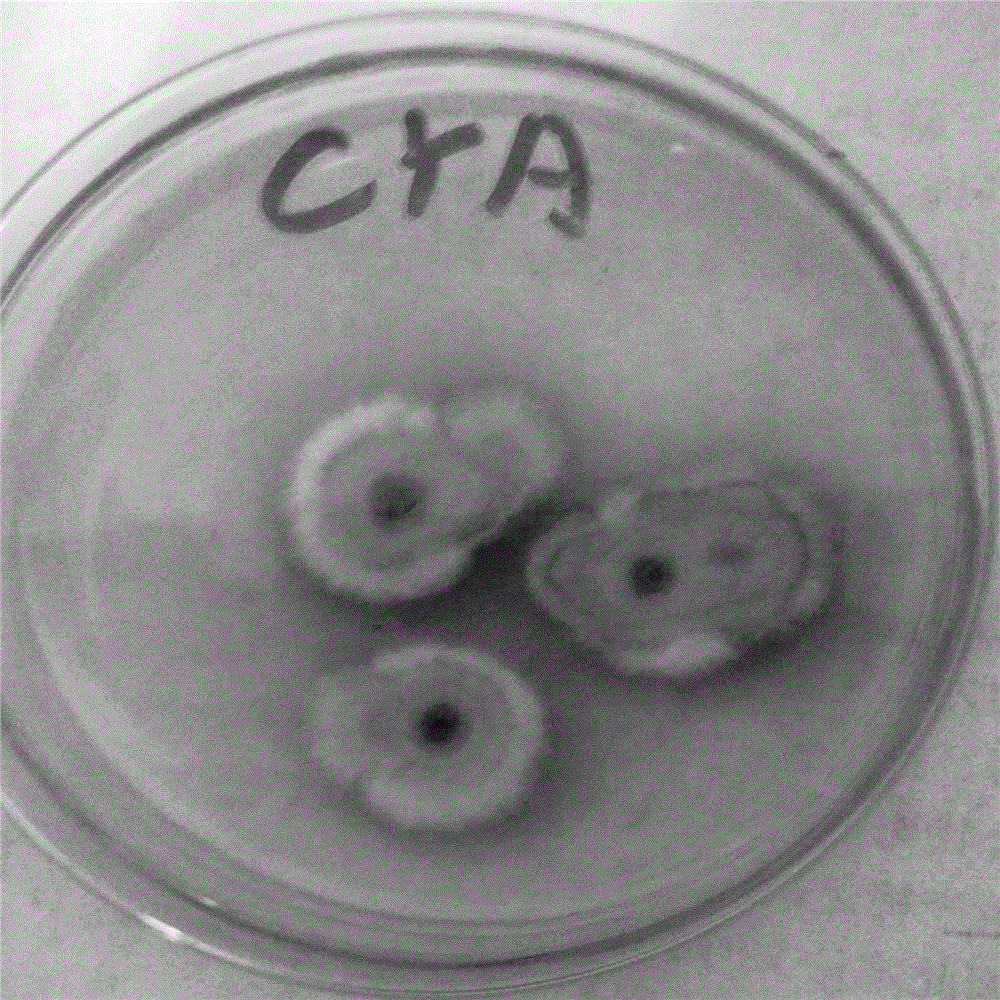

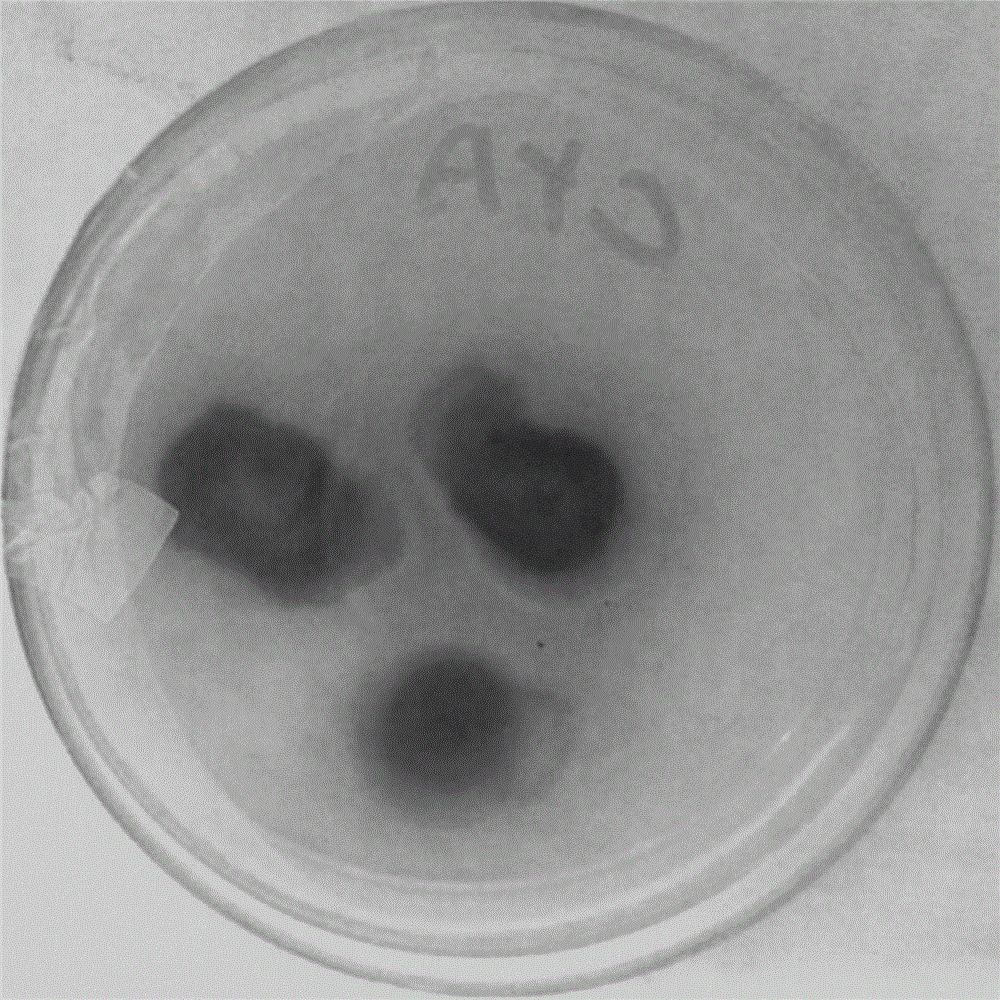

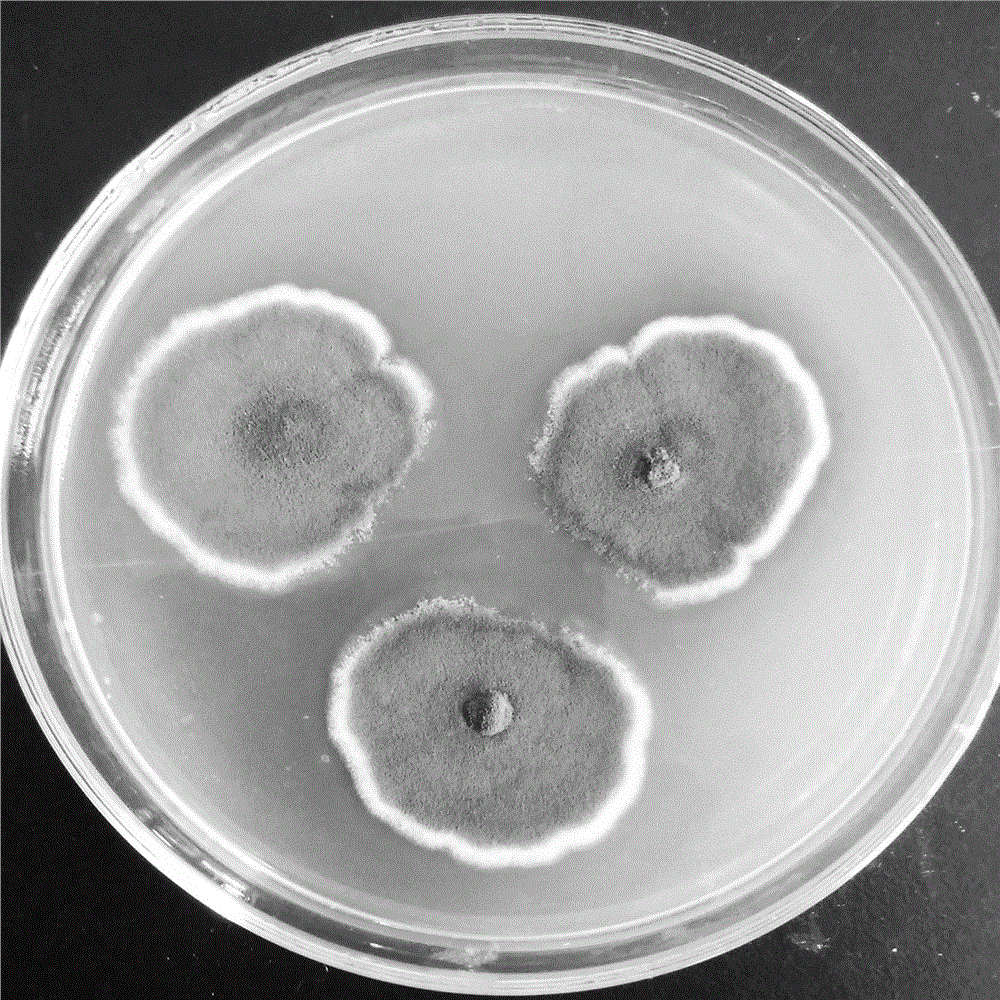

[0042] 1. Morphological observation and genomic DNA sequence analysis of Penicillium purpuragenicum EFOZ-02

[0043] (1) Morphological observation of Penicillium purpogenum EFOZ-02 strain

[0044] The morphology of the strain was observed as Figures 1 to 8 shown.

[0045] (2) Genomic DNA sequence analysis

[0046] Genomic DNA sequence analysis such as Figure 9 shown by Figure 9 It can be seen that the ITS gene region of Penicillium purpogenum in area 95 is the most similar to our strain EFOZ-02, and 95 is the closest to our strain.

[0047] 2. Preparation of ceramide

[0048] (1) Preparation of culture medium

[0049] A. Seed medium (Cha's medium)

[0050] Ingredients: 3g sodium nitrate, 1g dipotassium hydrogen phosphate, 0.5g magnesium sulfate, 0.5g potassium chloride, 0.01g ferrous sulfate, 30g sucrose, 1000mL distilled water.

[0051] Preparation method:

[0052] ① Weighing and ...

Embodiment 2

[0082] Example 2 Preparation of Ceramide

[0083] (1) Preparation of culture medium

[0084] A. Seed medium (Cha's medium)

[0085] Ingredients: sodium nitrate 3g, dipotassium hydrogen phosphate 1g, magnesium sulfate 0.5g, potassium chloride 0.5g, ferrous sulfate 0.01g, sucrose 30g, distilled water 1000mL.

[0086] Preparation method:

[0087] ①Weighing and melting: Measure about 2 / 3 of the required amount of water and add it to the beaker. Weigh sucrose, sodium nitrate, dipotassium hydrogen phosphate, potassium chloride, and magnesium sulfate, respectively, and add them into water one by one to dissolve. Add 1 mL of 0.1% ferrous sulfate solution to ml medium;

[0088] ②Add all the remaining water;

[0089] ③ Packing, plugging and dressing;

[0090] ④ High pressure steam sterilization: 100 Pa sterilization for 20 min.

[0091] B. Fermentation medium (PDA medium)

[0092] Ingredients: 200g potatoes, 20g sucrose, 2g peptone, 3g dipotassium hydrogen phosphate, 1g magnesiu...

Embodiment 3

[0110] Example 3 Preparation of Ceramide

[0111] (1) Preparation of culture medium

[0112] A. Seed medium (Cha's medium)

[0113] Ingredients: sodium nitrate 3g, dipotassium hydrogen phosphate 1g, magnesium sulfate 0.5g, potassium chloride 0.5g, ferrous sulfate 0.01g, sucrose 30g, distilled water 1000mL.

[0114] Preparation method:

[0115] ①Weighing and melting: Measure about 2 / 3 of the required amount of water and add it to the beaker. Weigh sucrose, sodium nitrate, dipotassium hydrogen phosphate, potassium chloride, and magnesium sulfate, respectively, and add them into water one by one to dissolve. Add 1 mL of 0.1% ferrous sulfate solution to ml medium;

[0116] ②Add all the remaining water;

[0117] ③ Packing, plugging and dressing;

[0118] ④ High pressure steam sterilization: 100 Pa sterilization for 20 min.

[0119] B. Fermentation medium (PDA medium)

[0120] Ingredients: 200g potatoes, 20g sucrose, 2g peptone, 3g dipotassium hydrogen phosphate, 1g magnesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com