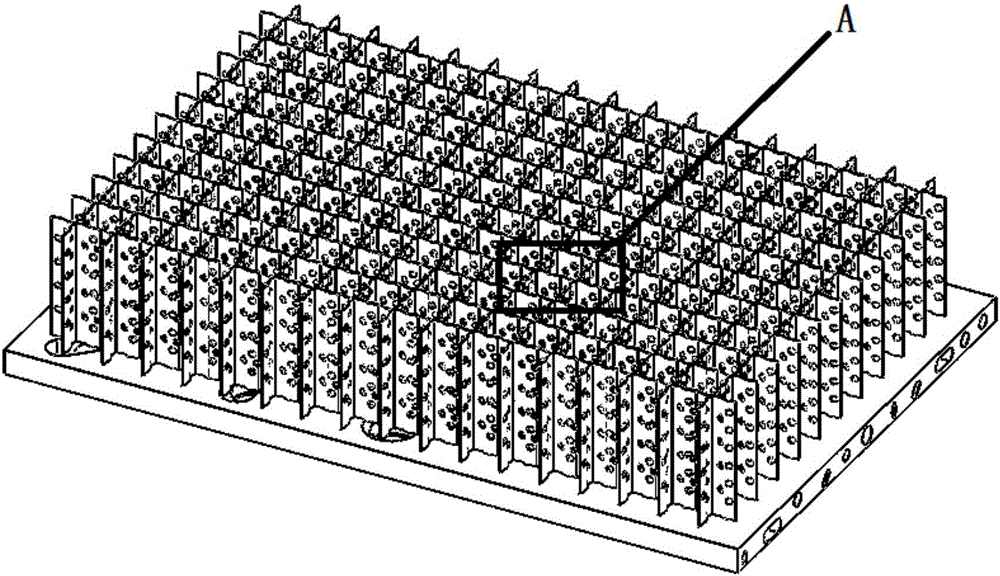

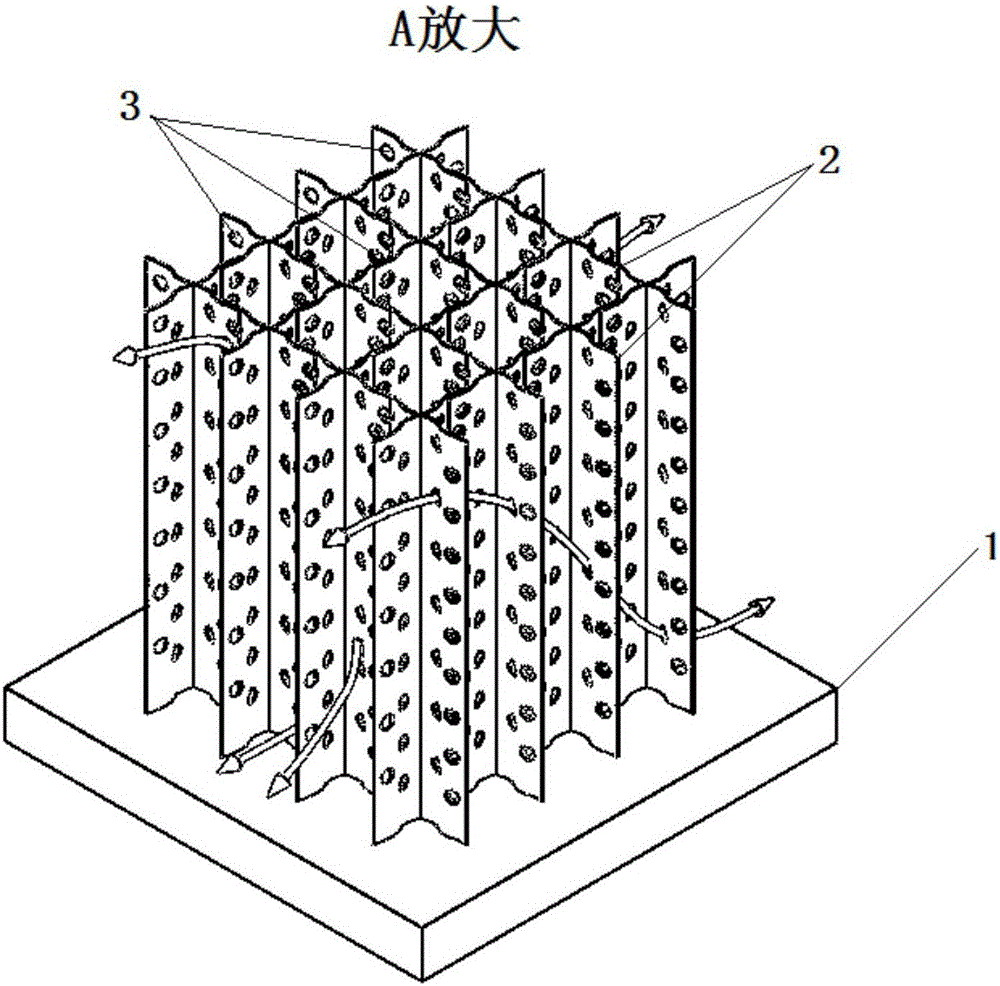

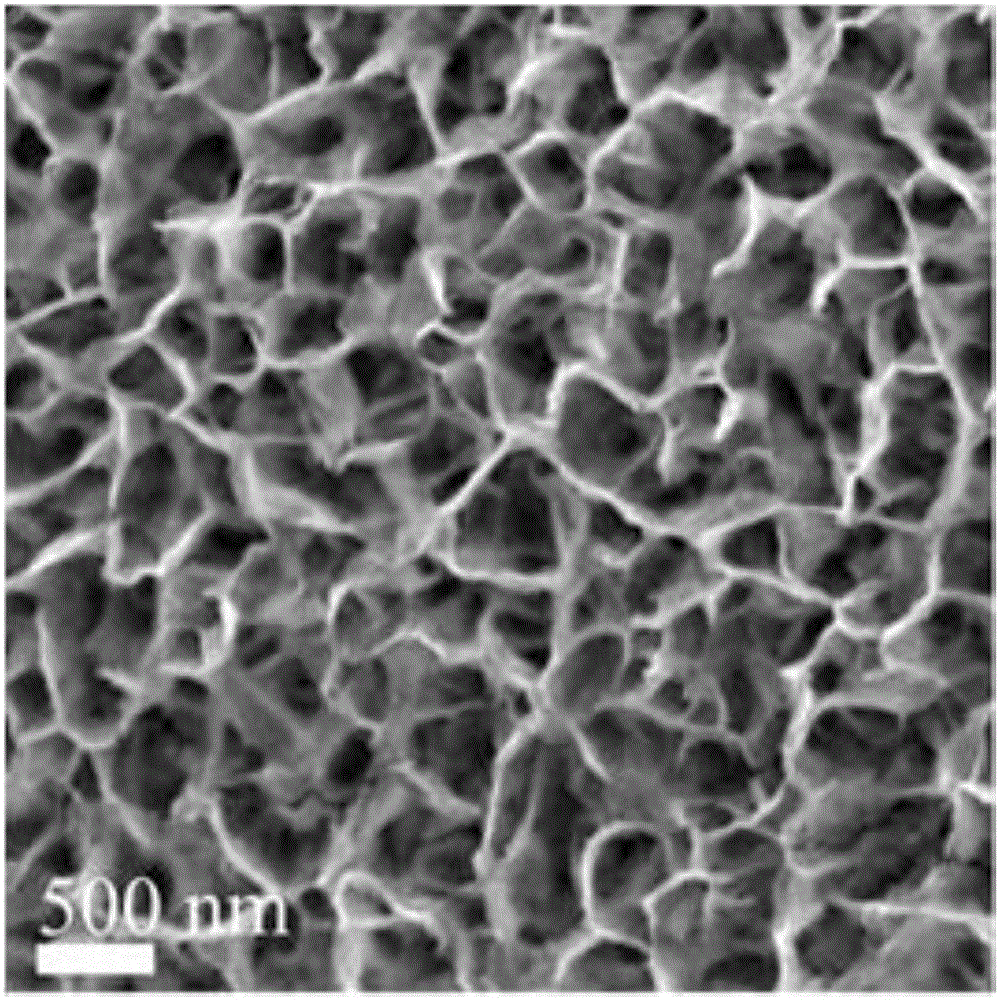

Pseudo capacitor electrode based on nickel/cobalt sulfide three-dimensional hierarchical nanostructure and preparation method thereof

A nanostructure, nickel-cobalt sulfide technology, applied in the field of electrodes, can solve the problems of difficult application requirements, poor cycle stability, and low energy density, and achieve the effects of improving cycle stability, increasing energy density, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A pseudocapacitor electrode based on a nickel-cobalt sulfide three-dimensional hierarchical nanostructure of the present embodiment is prepared as follows:

[0031] (1) Soak the foamed nickel with concentrated hydrochloric acid, then wash with water and an organic solvent to remove oxides and grease on the foamed nickel surface;

[0032] (2) Weigh 0.1molNi(NO 3 ) 2 ·6H 2 O, 1molCo(NO 3 ) 2 ·6H 2 O, 4.4mol Na 2 SO 4 Dissolved in an aqueous solution to obtain a mixed solution;

[0033] (3) Add the mixed solution in step (2) to the hydrothermal kettle containing nickel foam in step (1) to react, and make nickel foam containing cobalt nickel hydroxide nanosheets, wherein the nickel hydroxide nanosheets Located on nickel foam and interconnected in a honeycomb shape;

[0034] (4) the foamed nickel containing cobalt-nickel hydroxide nano-sheets prepared in step (3) is placed in sodium sulfide solution and reacted in a hydrothermal kettle, so that the cobalt-nickel hyd...

Embodiment 2

[0037] A pseudocapacitor electrode based on a nickel-cobalt sulfide three-dimensional hierarchical nanostructure of the present embodiment is prepared as follows:

[0038] (1) Soak the foamed nickel with concentrated hydrochloric acid, then wash with water and an organic solvent to remove oxides and grease on the foamed nickel surface;

[0039] (2) Weigh 1molNi(NO 3 ) 2 ·6H 2 O, 1molCo(NO 3 ) 2 ·6H 2 O, 4mol Na 2 SO 4 Dissolved in an aqueous solution to obtain a mixed solution;

[0040] (3) Add the mixed solution in step (2) to the hydrothermal kettle containing nickel foam in step (1) to react, and make nickel foam containing cobalt nickel hydroxide nanosheets, wherein the nickel hydroxide nanosheets Located on nickel foam and interconnected in a honeycomb shape;

[0041] (4) the foamed nickel containing cobalt-nickel hydroxide nano-sheets prepared in step (3) is placed in sodium sulfide solution and reacted in a hydrothermal kettle, so that the cobalt-nickel hydroxi...

Embodiment 3

[0044]A pseudocapacitor electrode based on a nickel-cobalt sulfide three-dimensional hierarchical nanostructure of the present embodiment is prepared as follows:

[0045] (1) Soak the foamed nickel with concentrated hydrochloric acid, then wash with water and an organic solvent to remove oxides and grease on the foamed nickel surface;

[0046] (2) Weigh 1molNi(NO 3 ) 2 ·6H 2 O, 0.2molCo(NO 3 ) 2 ·6H 2 O, 1.2mol Na 2 SO 4 Dissolved in an aqueous solution to obtain a mixed solution;

[0047] (3) Add the mixed solution in step (2) to the hydrothermal kettle containing nickel foam in step (1) to react, and make nickel foam containing cobalt nickel hydroxide nanosheets, wherein the nickel hydroxide nanosheets Located on nickel foam and interconnected in a honeycomb shape;

[0048] (4) the foamed nickel containing cobalt-nickel hydroxide nano-sheets prepared in step (3) is placed in thiourea solution and reacted in a hydrothermal kettle, so that cobalt-nickel hydroxide nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com