Ultrashort pulse fiber laser based on WS2/graphene heterojunction

A graphene and heterojunction technology, applied in lasers, laser components, phonon exciters, etc., can solve the problems of ineffective compression of pulse width, weak single atomic layer light absorption, small modulation depth, etc. To achieve the effect of convenient operation, stable quality and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

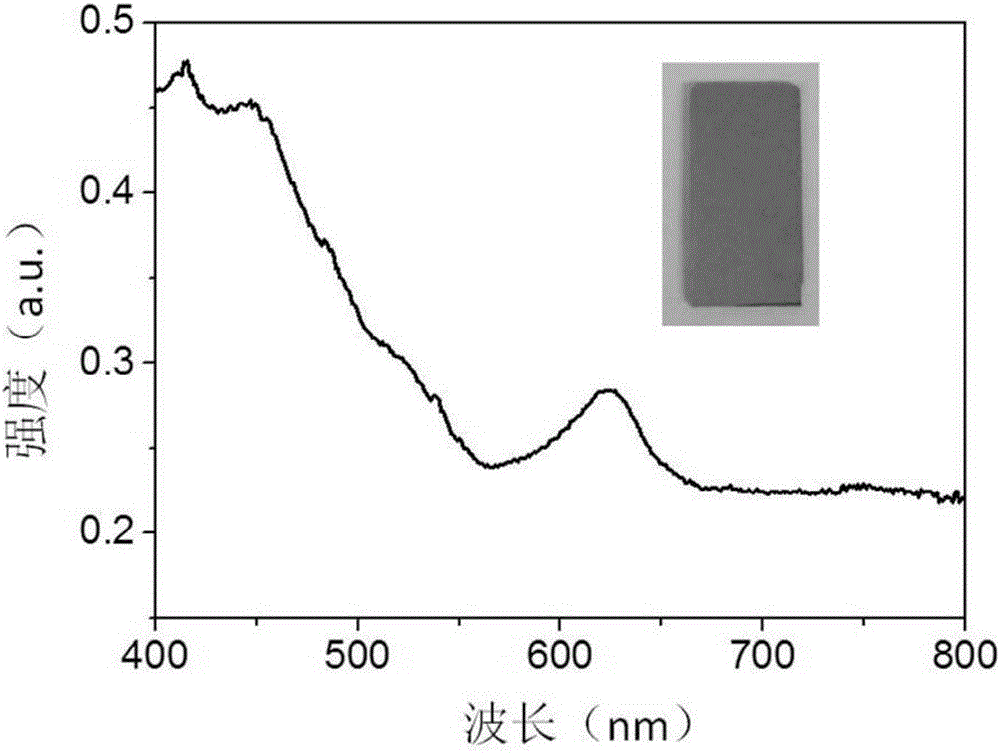

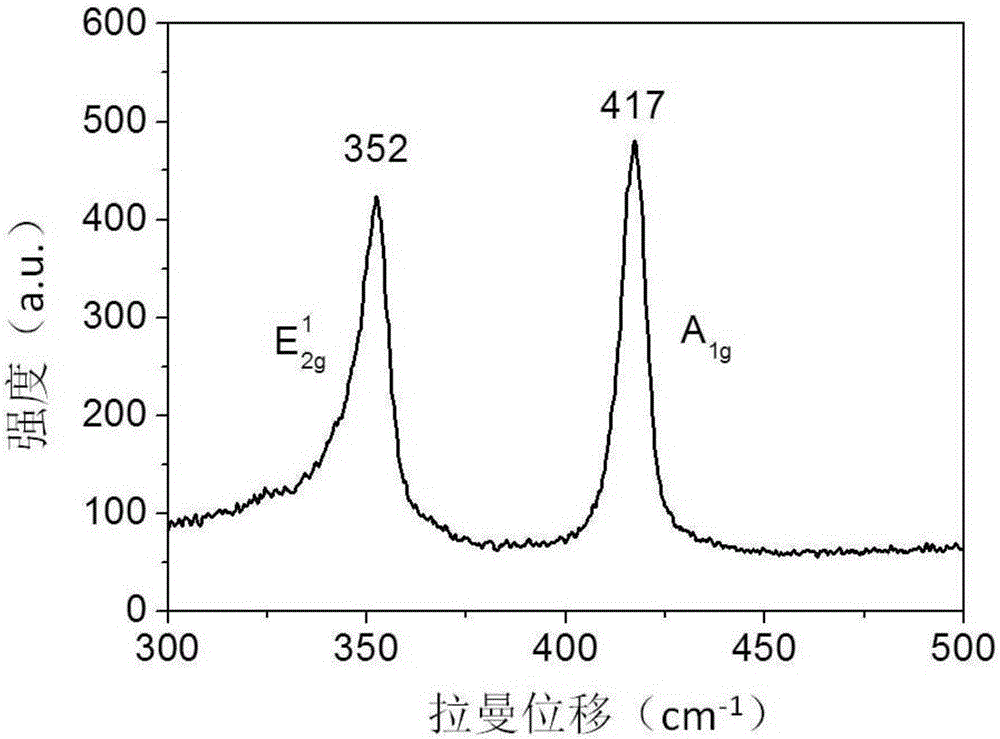

[0024] Step 1: Preparation of WS on quartz substrate by magnetron sputtering 2 film. Using WS 2 The polycrystalline block is used as the target material, the RF power is 60W, the argon gas pressure is 50Pa, the quartz substrate is heated to 200°C, and the deposition is continued for 10min. The film obtained by magnetron sputtering is placed in a tube furnace for heat treatment, and argon is used as a protective gas at a flow rate of 100 sccm. Place high-purity sulfur powder in the upstream low-temperature area, set the temperature at 200°C, and set the furnace center temperature at 800°C, keep it for 2 hours and then cool it down to room temperature naturally.

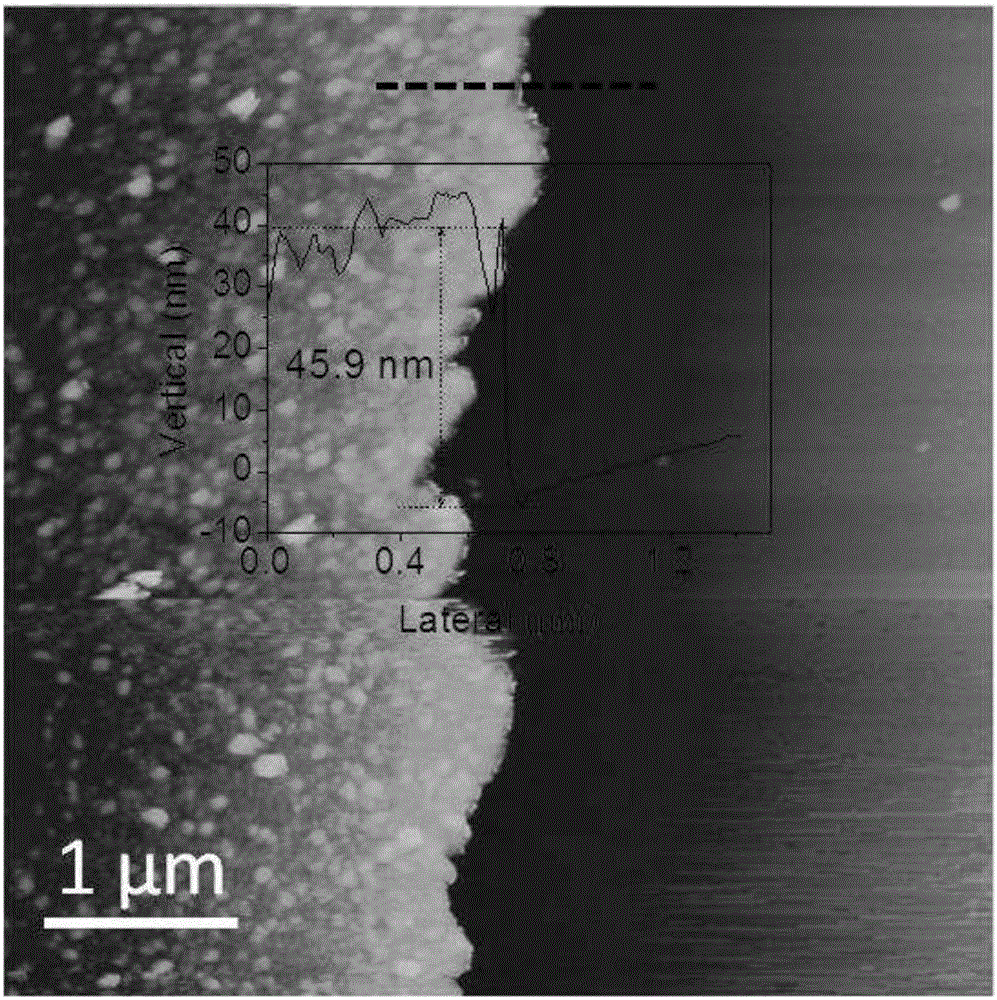

[0025] Step 2: Covering of graphene. The graphene grown on the copper substrate is cut into the required size and shape, and the surface is coated with a layer of 5% PMMA / anisole solution at a speed of 2000rpm for 30s, dried at 80°C, and then Soak it in a supersaturated solution of ammonium persulfate, etch away th...

Embodiment 2

[0029] Step 1: Preparation of WS on quartz substrate by magnetron sputtering 2 film. Using WS 2 The polycrystalline block is used as the target material, the RF power is 60W, the argon gas pressure is 50Pa, the quartz substrate is heated to 200°C, and the deposition is continued for 5min. The film obtained by magnetron sputtering is placed in a tube furnace for heat treatment, and argon is used as a protective gas at a flow rate of 100 sccm. Place high-purity sulfur powder in the upstream low-temperature area, set the temperature at 200°C, and set the furnace center temperature at 800°C, keep it for 2 hours and then cool it down to room temperature naturally.

[0030] Step 2: Covering of graphene. The graphene grown on the copper substrate is cut into the required size and shape, and the surface is coated with a layer of 5% PMMA / anisole solution at a speed of 2000rpm for 30s, dried at 80°C, and then Soak it in a supersaturated solution of ammonium persulfate, etch away the...

Embodiment 3

[0034] This embodiment provides a pulsed fiber laser, which includes a pump-based light source and a resonant cavity, and is characterized in that it also includes a WS 2 / graphene heterojunction thin film saturable absorber, the WS 2 The graphene heterojunction film saturable absorber is arranged on the gain fiber end face of the laser. The gain fiber is an ytterbium-doped fiber, the wavelength of the pump source is 980nm, and the center wavelength of the wavelength division multiplexer is 1064nm.

[0035] Wherein, the resonator is a ring cavity, including a wavelength division multiplexer, a gain fiber, a polarization-independent isolator, a polarization controller, a saturable absorber and a coupler connected in sequence to form a ring resonator; the pump light source and The input terminals of the wavelength division multiplexer are connected.

[0036] And the WS used in this embodiment 2 / The preparation of graphene heterojunction thin film saturable absorber comprise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com