Graphene oxide/ polymer gel as well as preparation method and application thereof

A graphene and polymer technology, applied in the directions of alkali metal oxides/hydroxides, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of low specific adsorption efficiency of dye wastewater and complex synthesis process, etc. To achieve the effect of easy operation, simple preparation process and simple adsorption process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

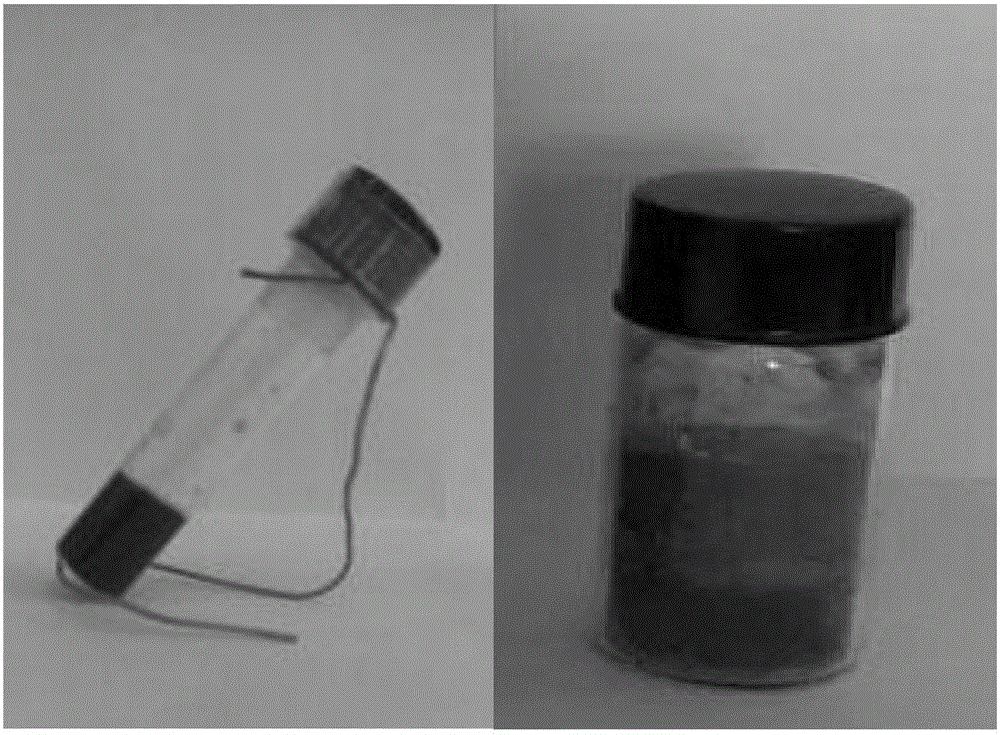

[0047] (1) Take polyacrylamide (PAM molecular weight ≥ 5 × 10 5 , Kermel, Tianjin, Q / 12HB 4083-2009) 50mg was added to a 5mg / mL graphene oxide solution to form a 10mL solution, and stirred at room temperature to mix evenly to obtain a graphene oxide / polyacrylamide gel. Such as figure 1 Shown in the middle left figure.

[0048] (2) Freeze-dry the prepared graphene oxide / polyacrylamide gel to obtain 100 mg xerogel. Such as figure 1 Shown in the figure on the right.

[0049] (3) Get the waste water containing cationic dyestuff (methylene blue), add dry graphene oxide / polyacrylamide xerogel to waste water, press graphene oxide / polyacrylamide gel and dyestuff mass ratio 3.3 in waste water: 1 Serve, shake to mix.

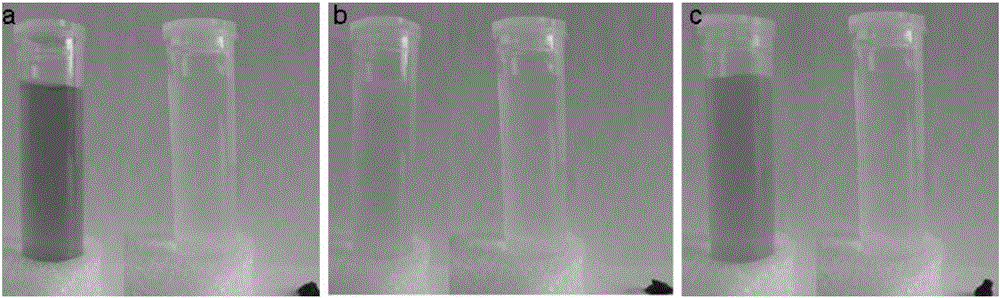

[0050] (4) The mixed solution after adsorption is separated from the gel and the aqueous solution with a filter cloth. Cationic dye (methylene blue) wastewater before and after adsorption figure 2 as shown in a.

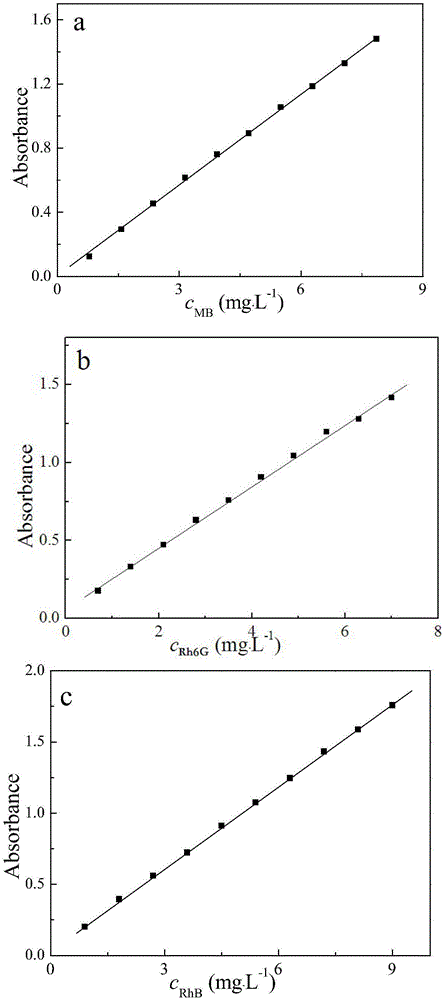

[0051] (5) According to the characteristic absorp...

Embodiment 2

[0054] (1) Take polyacrylamide (PAM molecular weight ≥ 5 × 10 5 , Kermel, Tianjin, Q / 12HB 4083-2009) 40mg was added to a 6mg / mL graphene oxide solution to make a 10mL solution, and stirred at room temperature to mix evenly to obtain a graphene oxide / polyacrylamide gel.

[0055] (2) Freeze-dry the prepared graphene oxide / polyacrylamide gel to obtain 100 mg xerogel.

[0056] (3) Get the waste water containing cationic dye (rhodamine 6G), add graphene oxide / polyacrylamide xerogel to waste water, and dye mass ratio 3.3 in graphene oxide / polyacrylamide gel and waste water: 1 Serve, shake to mix.

[0057] (4) The mixed solution after adsorption is separated from the gel and the aqueous solution with a filter cloth. Cationic dye (rhodamine 6G) wastewater before and after adsorption figure 2 as shown in b.

[0058] (5) According to the characteristic absorption wavelength of the cationic dye (rhodamine 6G), the standard curve of its concentration and absorbance was drawn, and the...

Embodiment 3

[0061] (1) Take polyacrylamide (PAM molecular weight ≥ 5 × 10 5 , Kermel, Tianjin, Q / 12HB 4083-2009) 60mg was added to 4mg / mL graphene oxide solution to make a 10mL solution, shake and stir at room temperature to mix evenly to obtain graphene oxide / polyacrylamide gel.

[0062] (2) Freeze-dry the prepared graphene oxide / polyacrylamide gel to obtain 100 mg xerogel.

[0063] (3) Get the wastewater containing cationic dyes (rhodamine B), add the dry graphene oxide / polyacrylamide gel to the wastewater, and press the graphene oxide / polyacrylamide gel to the dye mass ratio of 5 in the wastewater : 1 cast, oscillate to mix.

[0064] (4) The mixed solution after adsorption is separated from the gel and the aqueous solution with a filter cloth. Cationic dye (rhodamine B) wastewater before and after adsorption figure 2 as shown in c.

[0065] (5) According to the characteristic absorption wavelength of the cationic dye (rhodamine B), draw the standard curve of its concentration and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com