Bi-network high-intensity fibroin hydrogel and preparation method thereof

A silk protein, high-strength technology, used in medical science, prosthesis, tissue regeneration, etc., can solve the problems of limitation, surfactant cytotoxicity, lack of mechanical properties of hydrogels, etc., to achieve excellent performance and good repeatability , good biocompatibility and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

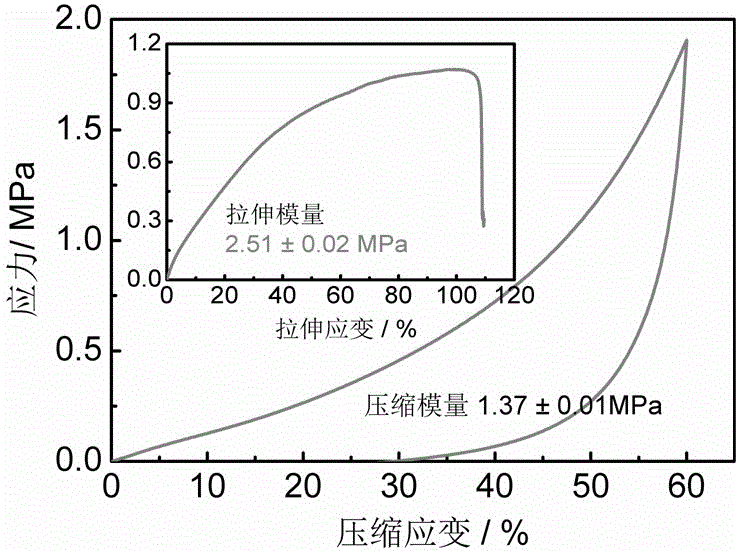

Embodiment 1

[0032] Take 2 mL of mulberry silk protein solution with a mass fraction of 10 wt%, add 40 μL of 0.5 mg / mL horseradish peroxidase, mix evenly, add 40 μL of 0.05% hydrogen peroxide aqueous solution, and form a gel at 37 °C network; then soak it in 75% ethanol solution for 24 h to obtain a high-strength silk protein hydrogel with a compressive modulus of 1.37 MPa and a tensile modulus of 3.35 MPa. Tests show that it has stable performance and good cell compatibility under simulated in vivo environmental conditions.

Embodiment 2

[0034] Take 4 mL of tussah silk protein solution with a mass fraction of 2 wt%, add 80 μL of 1 mg / mL horseradish peroxidase, mix evenly, add 80 μL of 0.2% hydrogen peroxide aqueous solution, and form a gel at 40 °C network; then soak it in 70% isopropanol solution for 12 h to obtain a high-strength silk protein hydrogel with a compressive modulus of 0.28 MPa and a tensile modulus of 0.2 MPa. Tests show that it has stable performance and good cell compatibility under simulated in vivo environmental conditions.

Embodiment 3

[0036] Take 2 mL of tussah silk protein solution with a mass fraction of 20 wt%, add 40 μL of 0.1 mg / mL horseradish peroxidase, mix evenly, add 40 μL of 0.01% hydrogen peroxide aqueous solution, and form a gel at 25 °C network; then soak it in 0.5M sodium dodecyl sulfate solution for 48 h to obtain a silk protein hydrogel with good mechanical properties, with a compressive modulus of 3.2 MPa and a tensile modulus of 3.5 MPa. Tests show that it has stable performance and good cell compatibility under simulated in vivo environmental conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compression modulus | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com