Photonic crystal assembled by fluorescent microspheres and preparation method and application thereof

A fluorescent microsphere and photonic crystal technology, applied in chemical instruments and methods, luminescent materials, semiconductor devices, etc., can solve the problem of difficulty in ensuring the consistency of LED photometric and chromaticity, difficult to control the thickness and uniformity of fluorescent powder glue, and affecting the use of LEDs. lifespan and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

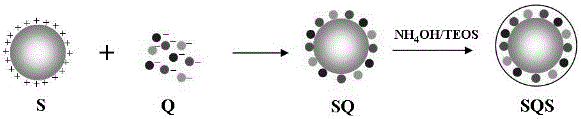

Method used

Image

Examples

Embodiment 1

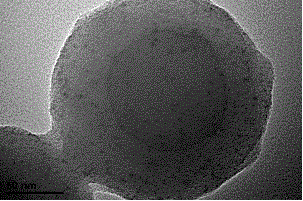

[0064] (1) Preparation of monodisperse silica particles:

[0065] Dissolve 6 ml of ammonia in water, add ethanol to make the total amount of trifoliate 50 ml, place it in a three-necked flask and stir at 25°C for 15 minutes, then measure 4.5 ml of ethyl orthosilicate (TEOS) and dissolve in 45.5 ml of ethanol. The ethanol solution of ethyl orthosilicate is added to the ammonia solution to keep the reaction system sealed and fully reacted for 24 hours. The obtained product was centrifuged, and the particles were washed three times with absolute ethanol and distilled water, and placed in a vacuum drying oven at 50 ℃ for 24 h to obtain silica particles.

[0066] (2) Preparation of fluorescent microspheres

[0067] (A) Surface modification of monodisperse silica particles: the silica particles obtained in step (1) are re-dispersed in methanol, and the concentration of silica is 2.5 wt%. Then add 3-aminopropyltriethoxysilane APTMS (mass accounts for SiO 2 5wt%), the solution was heated u...

Embodiment 2

[0078] (1) Preparation of monodisperse silica particles:

[0079] Measure 15 ml of cyclohexane and place it in a three-necked flask. Under the condition of magnetic stirring, add 3.6 ml of surfactant (Triton X-100) and a certain amount of co-surfactant (n-hexanol, normal Octanol or n-heptanol), keep its concentration at 1.15 mol / L, stir vigorously at 30 ℃ for 5 min, then add a certain amount of distilled water to it, and continue to stir for 30 min to form a water-in-oil reverse phase micro Lotion. Under the condition of constant temperature and stirring, add 0.6 mL of ammonia and 0.6 ml of TEOS to the system, fully react for 24 h, add 30 ml of acetone to demulsify and terminate the reaction. After standing for a period of time, the resulting product is heated at 15000 rpm. After centrifugal separation under the conditions, the microspheres were washed three times with absolute ethanol and distilled water, and placed in a vacuum drying oven at 50 ℃ for 24 h to obtain silica part...

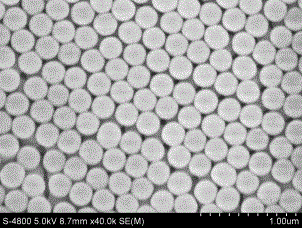

Embodiment 3

[0091] (1) Monodisperse silica particles are purchased directly, the monodispersity is below 3%, and the particle size is 150-200 nm. Monodisperse silica particles with a particle size of 160 nm are selected as seeds.

[0092] (2) Preparation of fluorescent microspheres

[0093] (A) Surface modification of monodisperse silica particles: re-disperse the silica particles in methanol, and the concentration of silica is 5wt%. Then add aminosilane (10wt% for SiO 2 ), the solution was heated at reflux overnight, centrifuged, the obtained powder was washed 2-3 times with methanol and deionized water, and finally dispersed in ethanol to obtain an amino-modified silica solution. The silica concentration was 2%. The hydrochloric acid solution adjusts the pH value of the amino modified silica solution so that the pH value is around 4.

[0094] (B) Surface modification of quantum dots: Red, green and blue quantum dots CdSe / ZnS (purchased from Adrich) modified by octadecylamine were dispersed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com