High-frequency electron tube booster circuit

A booster circuit and electron tube technology, applied in electrical components, adjusting electrical variables, instruments, etc., can solve the problems of increased difficulty in stabilizing power supply, damage, high gain, etc., to overcome overheating damage or excessive consumption, improve performance and service life and the effect of improving the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

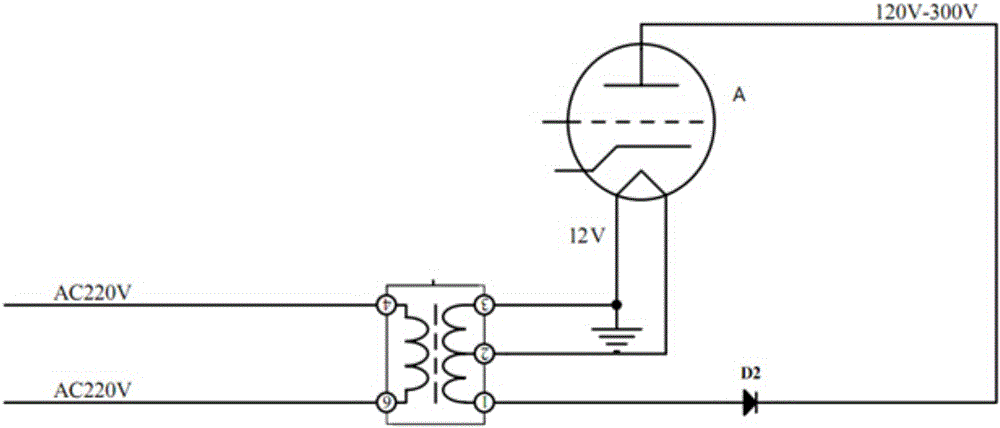

[0017] See attached figure 1 , the traditional low-frequency electronic tube power supply circuit, its input terminal is directly connected to the 220V mains, it is easy to be infected with AC noise, which is extremely unfavorable for improving the signal-to-noise ratio; and under the current power supply status in our country, it is necessary to ensure that the output It is also difficult to maintain the voltage at 6.3V, and the instability of the filament power supply will seriously affect the life of the tube.

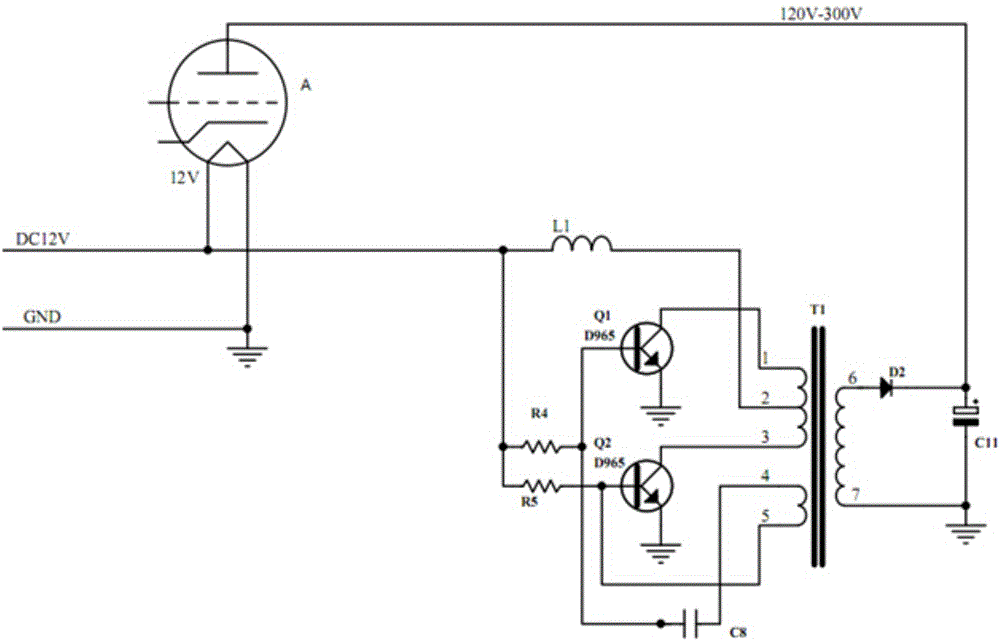

[0018] See attached figure 2 , the high-frequency tube booster circuit of the present invention has a DC voltage input terminal, and the circuit specifically includes an electronic transistor A, an inductor L1, a triode Q1, a triode Q2, a high-frequency transformer T1, a capacitor C8, an electrolytic capacitor C11, a resistor R4 and a resistor R5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com