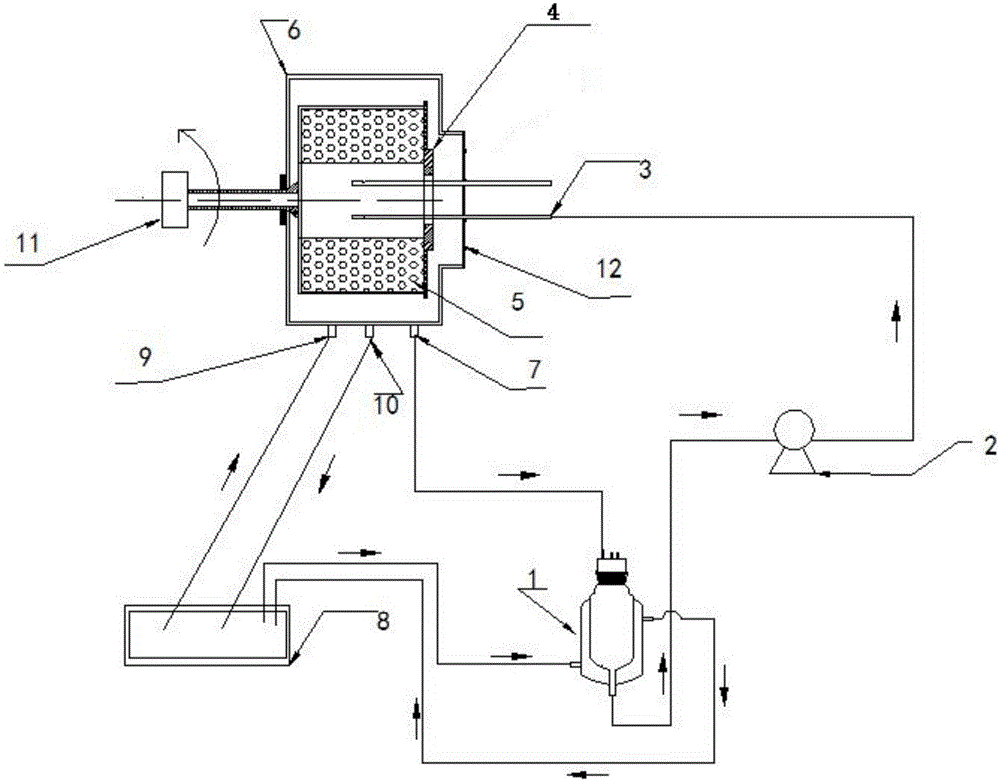

Improved rotating packed bed reactor for enzyme catalysis and application of reactor in fatty acid preparation through enzyme catalysis lipid hydrolysis

A technology of rotating packed bed and reactor, which is applied in the direction of enzyme production/bioreactor, specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, etc., which can solve the problem of unsaturated fatty acid decomposition and rearrangement Reaction, enzyme-catalyzed substrate microscopic mixing effect is poor, cannot meet the needs of high-quality products, etc., to achieve the effect of good contact, shortened reaction time, and increased yield of fatty acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Using the rotary packed bed reactor of the present invention, the supergravity level of the rotary bed is adjusted to 120 g, and the filler is stainless steel mesh. Add 150g of soybean oil with an acid value of 1.2mgKOH / g, mix evenly with an oil-water ratio of 1:1, control the temperature of the reaction system at 40°C, add 3g of Candida Antarctica lipase with an enzyme activity of 43000U, and the flow rate of the substrate is 120mL / min. After 24 hours of reaction, the peristaltic pump feeding and the rotating packed bed were stopped, and the fatty acid yield was 90.79%.

Embodiment 2

[0040] Using the rotary packed bed reactor of the present invention, the supergravity level of the rotary bed is adjusted to 15 g, and the filler is stainless steel mesh. Add 150g of soybean oil with an acid value of 1.2mgKOH / g, mix evenly with an oil-water ratio of 5:6, control the temperature of the reaction system at 40°C, add 3.3g of Candida sp. min. After 24 hours of reaction, the peristaltic pump feeding and the rotating packed bed were stopped, and the yield of fatty acid was 95.37%.

Embodiment 3

[0042] Using the rotary packed bed reactor of the present invention, the supergravity level of the rotary bed is adjusted to 15 g, and the filler is stainless steel mesh. Add 150 g of palm oil with an acid value of 0.75 mgKOH / g, mix evenly with an oil-water ratio of 5:7, control the temperature of the reaction system at 50°C, add 3.3 g of Candida Antarctica free lipase with an enzyme activity of 43,000 U, and flow rate of 80 mL / min. After 20 hours of reaction, the peristaltic pump feeding and the rotating packed bed were stopped, and the yield of fatty acid was 91.37%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com