Chelate resin, preparation method thereof and application thereof in nickel-copper containing solution deep copper removal

A chelating resin and solution technology, applied in chemical instruments and methods, other chemical processes, photographic technology, etc., can solve the problems of poor selectivity of copper-nickel separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

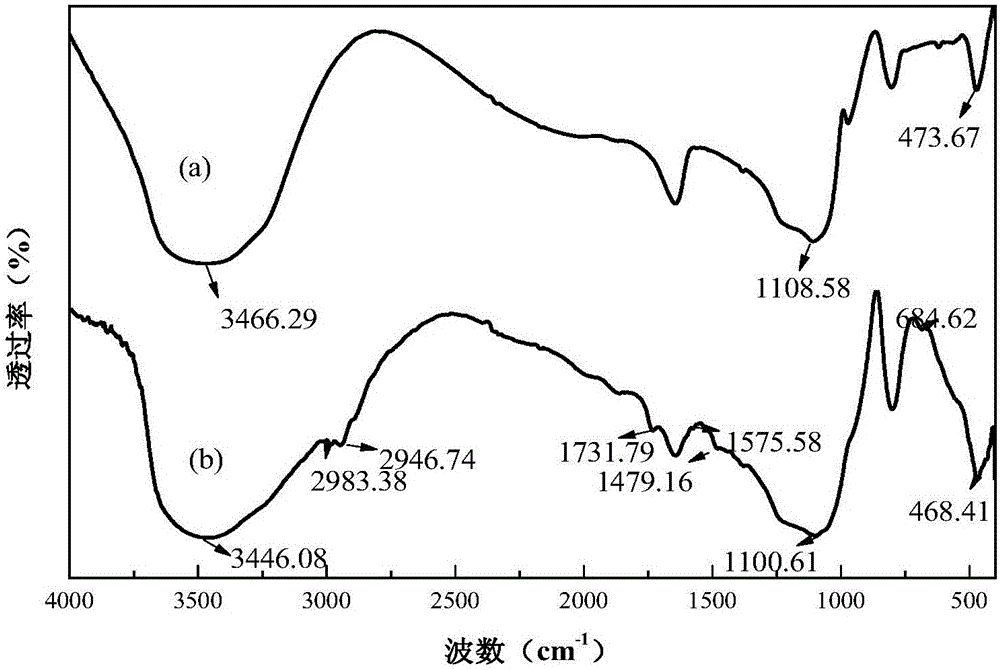

[0083] (a) Preparation of N-(tert-butoxycarbonyl methylene)-2-aminomethylpyridine

[0084] Under the protection of an inert atmosphere, mix 2-aminomethylpyridine, triethylamine, potassium iodide, and absolute ethanol evenly, then add tert-butyl bromoacetate drop by drop, react at room temperature for 8-20 hours, and add 2M Sodium chloride was extracted with ethyl acetate, then anhydrous magnesium sulfate was added and left to stand overnight, filtered, and the filtrate was purified by column chromatography after rotary evaporation to obtain N-(tert-butoxycarbonylmethylene)-2-ammonia picoline (AMPY-1). Table 1 adopts the relationship between N-(tert-butoxycarbonylmethylene)-2-aminomethylpyridine and productive rate prepared by different raw material ratios

[0085]

[0086]

Embodiment 5~8

[0088] (a) Preparation of N-(tert-butoxycarbonyl methylene)-2-aminomethylpyridine

[0089] Under the protection of an inert atmosphere, after mixing 10.23mL 2-aminomethylpyridine, 16.73mL triethylamine, 0.053g potassium iodide, and 150mL absolute ethanol, add 14.41mL tert-butyl bromoacetate drop by drop, and react at room temperature 8 to 20 hours, after the reaction is complete, add 2M sodium chloride and extract with ethyl acetate, then add anhydrous magnesium sulfate and let it stand overnight, filter, and the filtrate is purified by column chromatography after rotary evaporation to obtain N-(tert-butoxy Carbonylmethylene)-2-aminomethylpyridine (AMPY-1) in 55% yield.

[0090] (b) Preparation of 2-aminomethylpyridine modified silane coupling agent containing both tertiary amine groups and ester groups

[0091] Under the protection of an inert atmosphere, after mixing 3-chloropropyltrimethoxysilane, triethylamine, and N,N-dimethylformamide (DMF) evenly, add N-(tert-butoxycar...

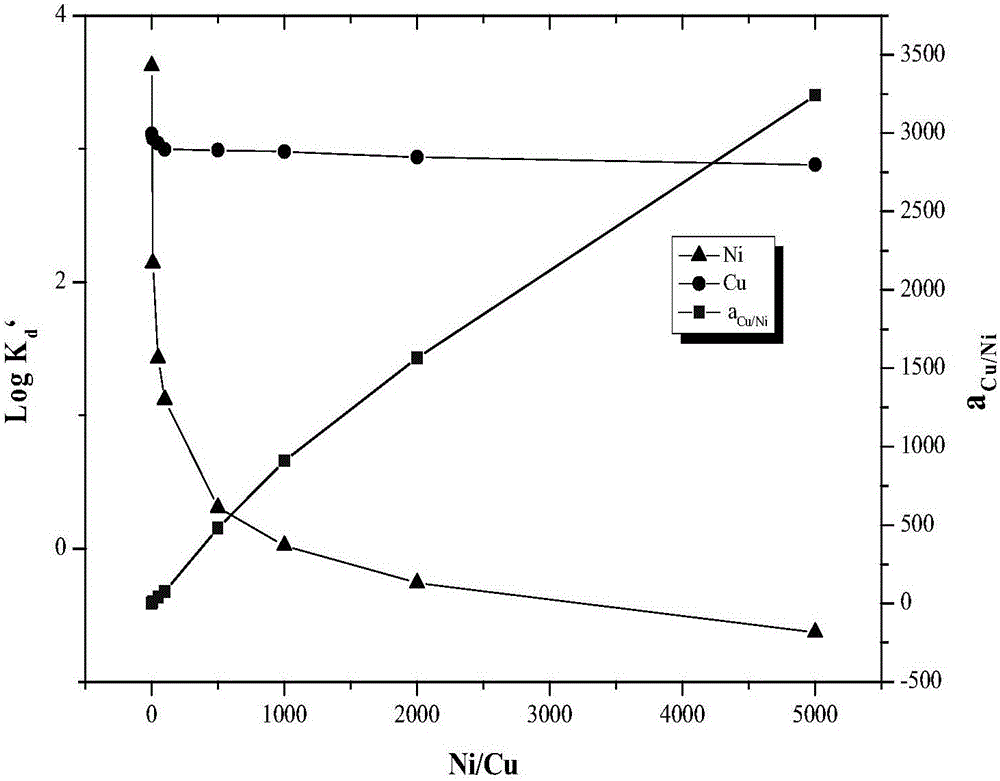

Embodiment 9~12

[0096] (a) Preparation of N-(tert-butoxycarbonyl methylene)-2-aminomethylpyridine

[0097] Under the protection of an inert atmosphere, after mixing 10.23mL 2-aminomethylpyridine, 16.73mL triethylamine, 0.053g potassium iodide, and 150mL absolute ethanol, add 14.41mL tert-butyl bromoacetate drop by drop, and react at room temperature 8 to 20 hours, after the reaction is complete, add 2M sodium chloride and extract with ethyl acetate, then add anhydrous magnesium sulfate and let it stand overnight, filter, and the filtrate is purified by column chromatography after rotary evaporation to obtain N-(tert-butoxy Carbonylmethylene)-2-aminomethylpyridine (AMPY-1) in 55% yield.

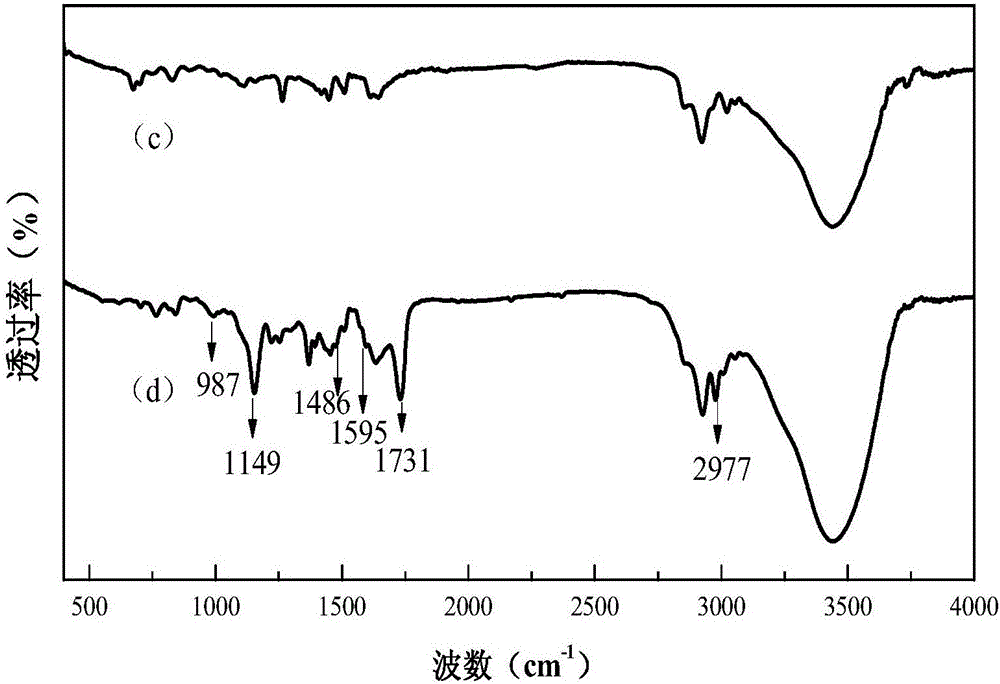

[0098] (b) Preparation of chelating resin with functional groups grafted on silica gel matrix

[0099] Under the protection of an inert atmosphere, after mixing 3-chloropropyltrimethoxysilane, triethylamine, and N,N-dimethylformamide (DMF) evenly, add N-(tert-butoxycarbonylmethylene base)-2-aminomethylpyrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com