Preparation method and application of lignin-based hydrothermal-carbon sulfonic acid catalyst

A technology based on lignin and carbon sulfonic acid, applied in chemical instruments and methods, physical/chemical process catalysts, applications, etc., can solve problems that do not meet the principles of green environmental protection, quality reduction, pore collapse, etc., and achieve sustainable development , easy separation, and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

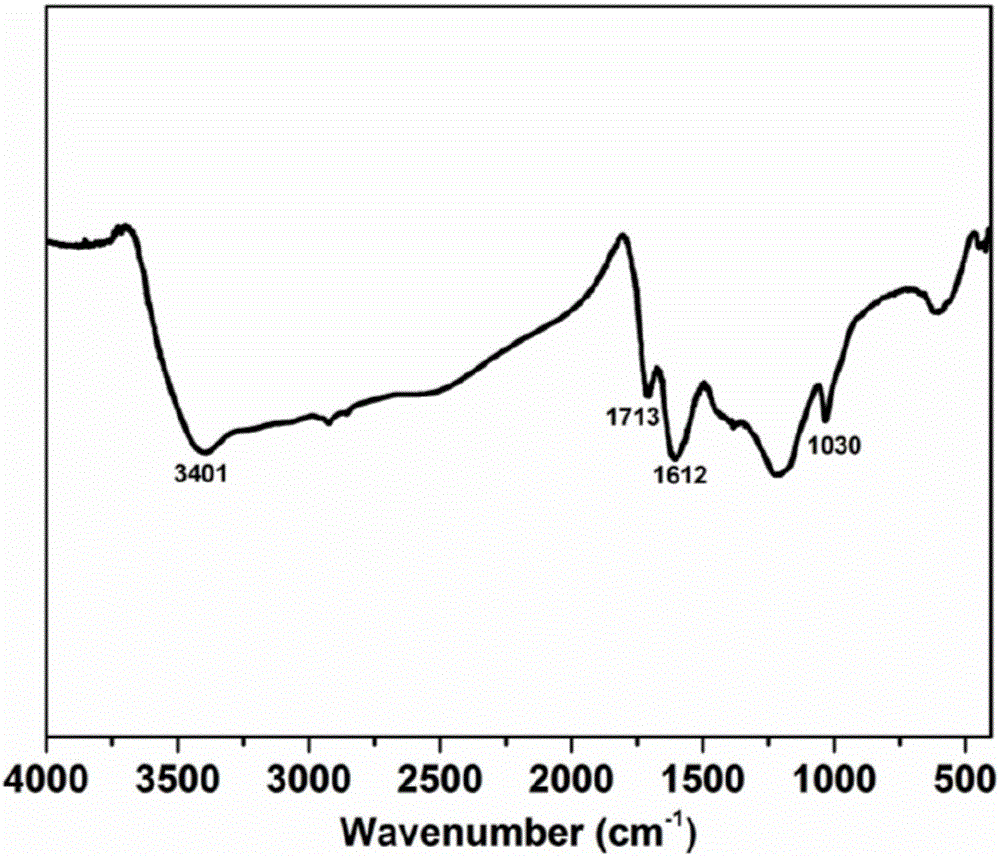

[0024] About 100 g of industrial alkali lignin containing ash is subjected to alkali-dissolving acid analysis treatment: the crude alkali lignin is dissolved in 10% aqueous sodium hydroxide solution so that the mass fraction of the lignin solution is not greater than 10%, and the insoluble matter is removed by filtration to obtain Purified alkali lignin solution. Then, at a temperature of 60° C. and a stirring speed of 200 rpm, concentrated sulfuric acid was added to make the solution pH=3, and stirred for 6 hours. The acidified lignin was washed with a large amount of distilled water to neutralize the centrifuged sediment, and then dried in an oven at 50°C for 48 hours to obtain refined lignin. Grind the refined alkali lignin, pass it through a 90-120 mesh sieve, then mix it with water at a mass ratio of 1:10, ultrasonically impregnate for 30 minutes to become a suspension, and carry out hydrothermal carbonization in a hydrothermal reaction kettle with a hydrothermal temperat...

Embodiment 2

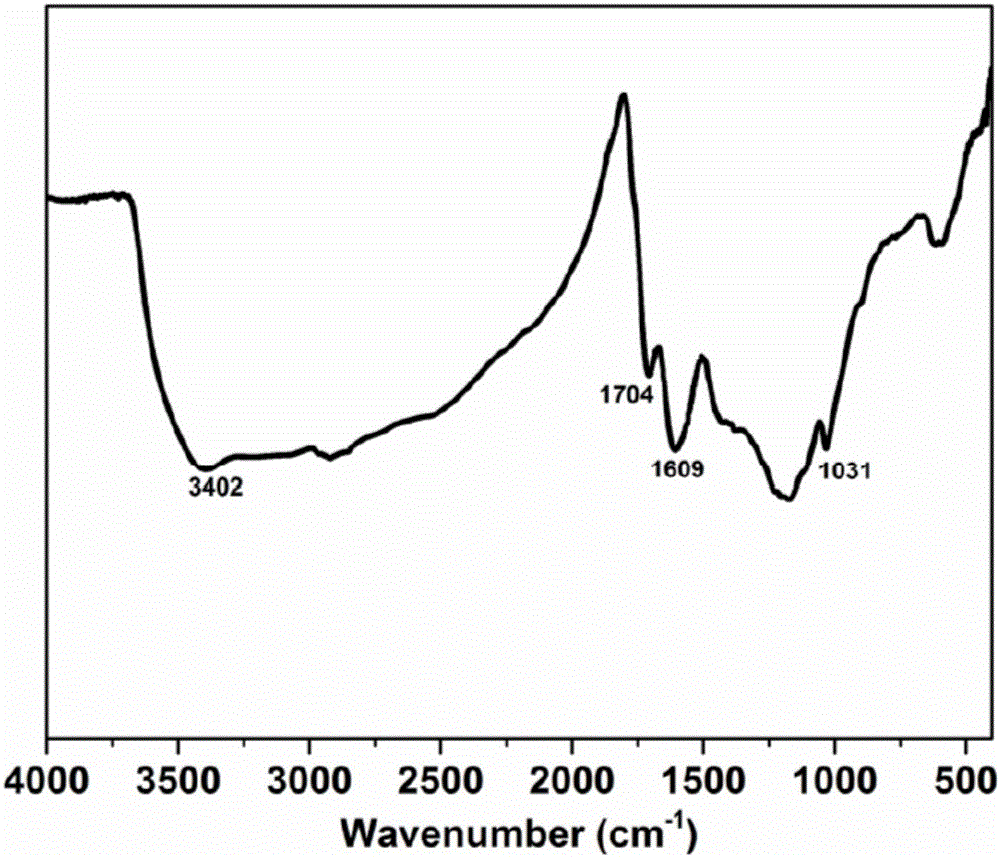

[0026] About 100 g of industrial alkali lignin containing ash is subjected to alkali-dissolving acid analysis treatment: the crude alkali lignin is dissolved in 10% aqueous sodium hydroxide solution so that the mass fraction of the lignin solution is not greater than 10%, and the insoluble matter is removed by filtration to obtain Purified alkali lignin solution. Then, at a temperature of 80° C. and a stirring speed of 180 rpm, concentrated sulfuric acid was added to make the solution pH=3, and stirred for 3 hours. The acidified lignin was washed with a large amount of distilled water to neutralize the centrifuged sediment, and then dried in an oven at 50°C for 48 hours to obtain refined lignin. Grind the refined alkali lignin, pass it through a 90-120 mesh sieve, then mix it with water at a mass ratio of 1:10, ultrasonically impregnate it for 15 minutes to become a suspension, add 20wt% citric acid and mix evenly, and carry out in a hydrothermal reaction kettle Hydrothermal ...

Embodiment 3

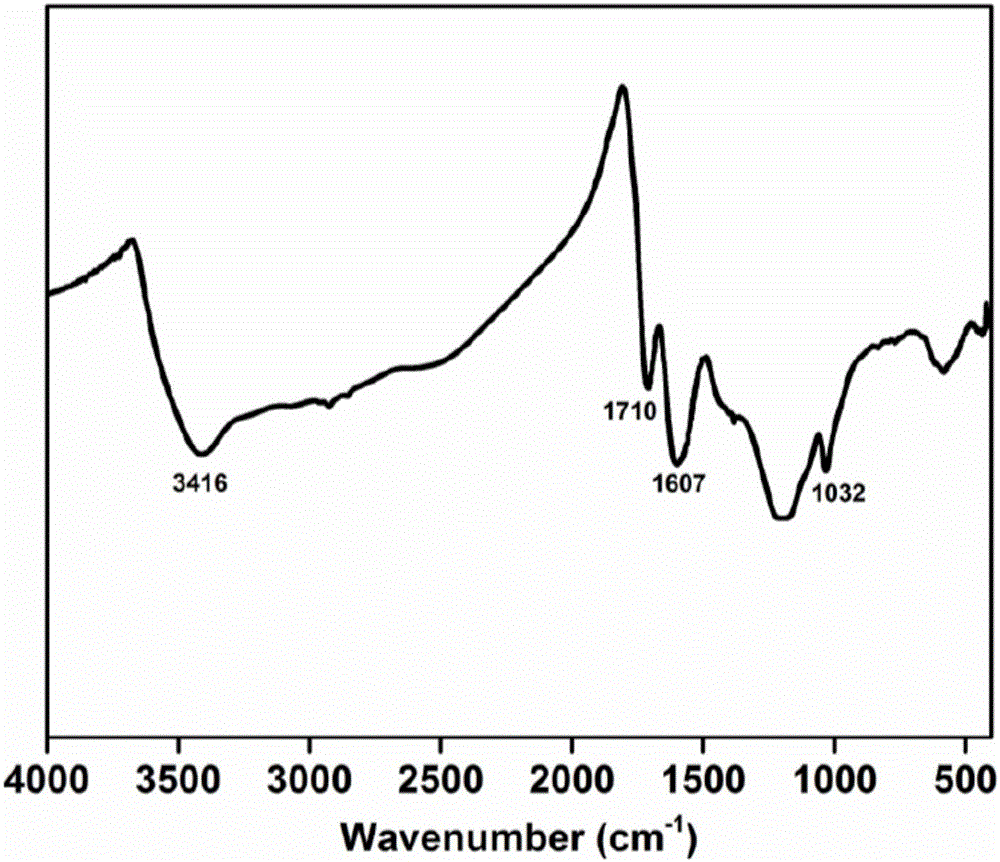

[0028]About 100 g of industrial alkali lignin containing ash is subjected to alkali-dissolving acid analysis treatment: the crude alkali lignin is dissolved in 10% aqueous sodium hydroxide solution so that the mass fraction of the lignin solution is not greater than 10%, and the insoluble matter is removed by filtration to obtain Purified alkali lignin solution. Then, at a temperature of 80° C. and a stirring speed of 200 rpm, concentrated sulfuric acid was added to make the solution pH=3, and stirred for 3 hours. The acidified lignin was washed with a large amount of distilled water to neutralize the centrifuged sediment, and then dried in an oven at 50°C for 48 hours to obtain refined lignin. Grind the refined alkali lignin, pass it through a 90-120 mesh sieve, then mix it with water at a mass ratio of 1:10, ultrasonically impregnate it for 20 minutes to become a suspension, add 40wt% acrylic acid and mix evenly, and carry out water heating in a hydrothermal reaction kettle....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com