A self-adhesive polymer pre-laid waterproof membrane and its preparation method

A waterproofing membrane and polymer technology, which is applied in chemical instruments and methods, layered products, synthetic resin layered products, etc. and other problems, to achieve the effect of strong anti-ultraviolet ability, control of water channeling phenomenon, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

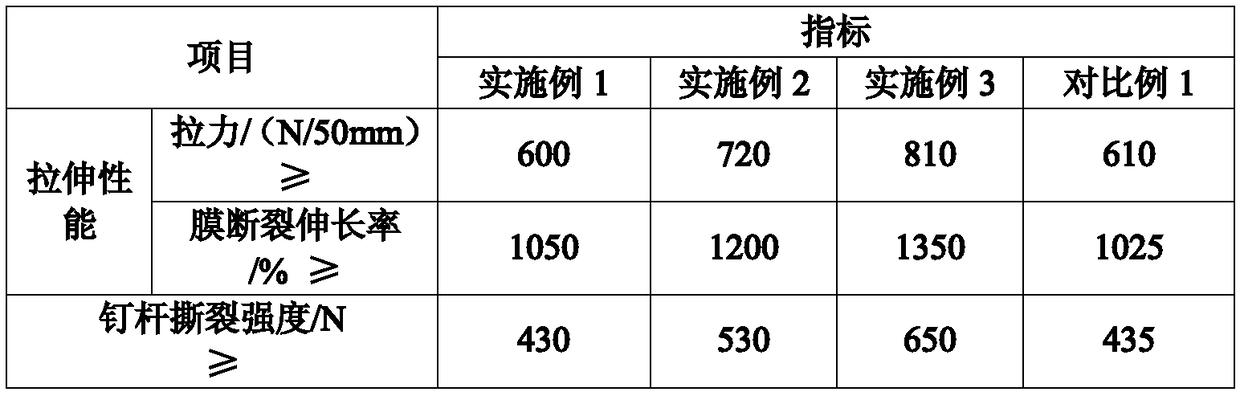

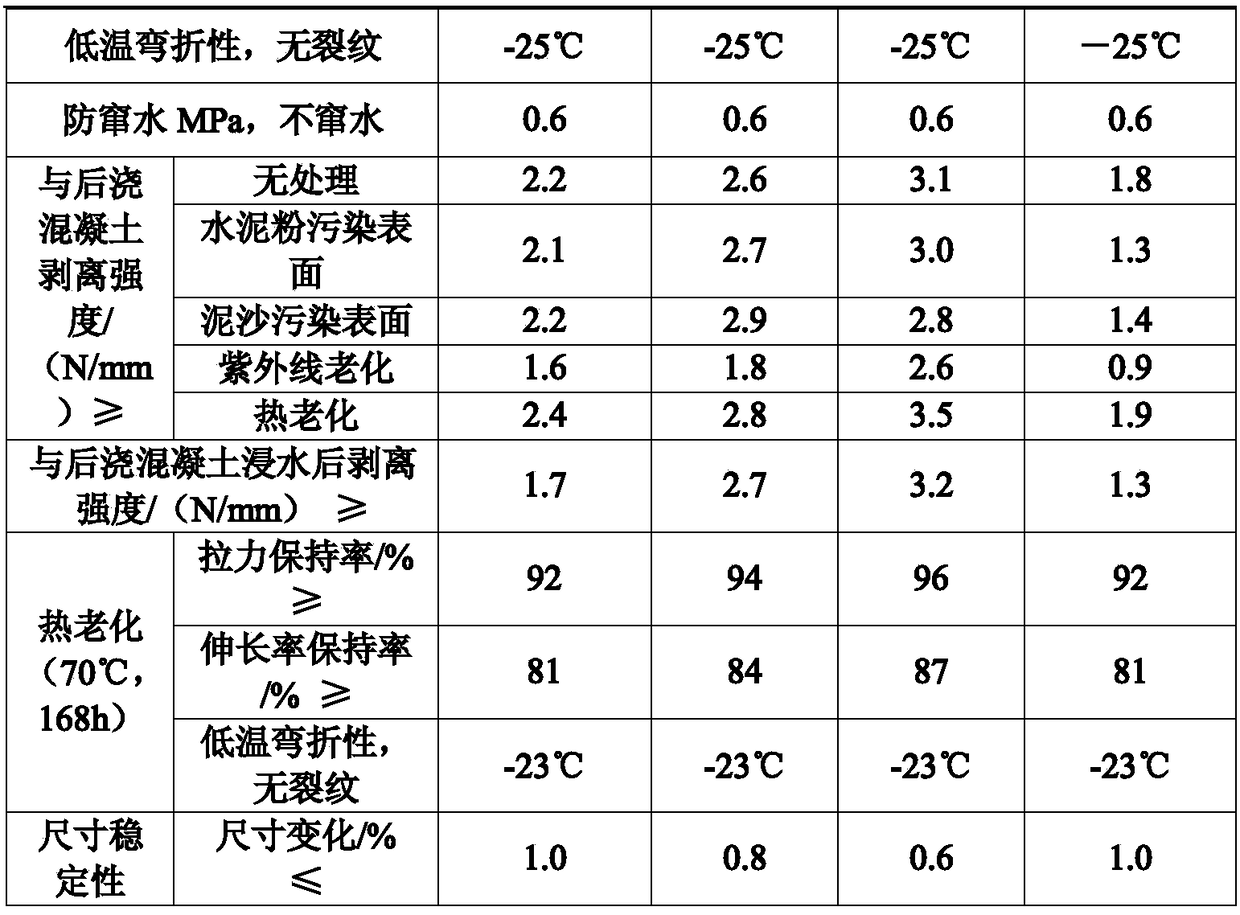

Embodiment 1

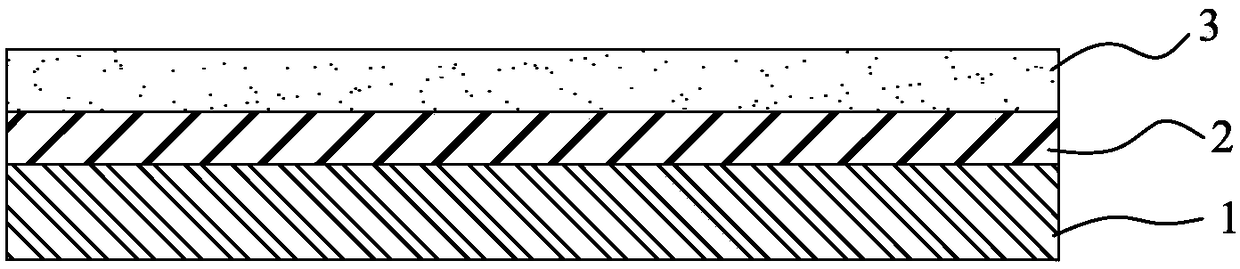

[0032] This embodiment provides a self-adhesive macromolecule pre-laid waterproof roll, such as figure 1 As shown, the waterproof membrane has a three-layer structure, including a sheet-like polymer substrate layer 1, a hot-melt pressure-sensitive adhesive layer 2 formed on the sheet-like polymer substrate layer 1, and a hot-melt pressure-sensitive adhesive layer arranged on the sheet-like polymer substrate layer. 2 on the anti-stick layer 3.

[0033] In this example, the raw materials used for the sheet polymer substrate layer 1 are high-density polyethylene pellets and low-density polyethylene pellets in a mass ratio of 1:1, which are mixed at high and low speeds and sent to the twin-screw extruder to be shaped by the die head. A waterproof sheet with a thickness of 1.0mm is made, and the temperature of each section of the twin-screw extruder is controlled, the temperature of the feeding section is at room temperature, the temperature of the compression section is 120-160°C,...

Embodiment 2

[0040] This embodiment provides a self-adhesive polymer pre-laid waterproof membrane.

[0041] The raw material used for the sheet-like polymer substrate layer 1 of the waterproof roll material in this example is a combination of high-density polyethylene and polyvinyl acetate particles in a mass ratio of 8:2.

[0042]The raw material of the hot-melt pressure-sensitive adhesive layer 2 is SIS rubber: naphthenic oil: hydrogenated petroleum resin in a mass ratio of 30:24:46, and 3‰ and 5% of the total weight of the hot-melt pressure-sensitive adhesive are added to the raw material. ‰ antioxidant bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide, UV stabilizer 2-hydroxy-4-methoxybenzophenone. The thickness of the hot-melt pressure-sensitive adhesive layer 2 is 0.3mm.

[0043] The raw materials of anti-sticking mineral particles are 99.62% of special white cement, 0.3% of polycarboxylate water reducer, 0.06% of defoamer, and 0.02% of retarder. The particle size distribution is 8% ...

Embodiment 3

[0046] This embodiment provides a self-adhesive polymer pre-laid waterproof membrane.

[0047] The raw material used for the sheet-like polymer substrate layer 1 of the waterproof roll material in this example is a combination of high-density polyethylene, low-density polyethylene, and polyvinyl acetate particles in a mass ratio of 6:3:1.

[0048] The raw material of the hot-melt pressure-sensitive adhesive layer 2 is SIS rubber: polybutadiene: hydrogenated carbon nine petroleum resin in a mass ratio of 28:28:42, and 3‰ of the total weight of the hot-melt pressure-sensitive adhesive is added to the raw material , 5‰ antioxidant bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide, UV stabilizer 2-hydroxy-4-methoxybenzophenone. The thickness of the hot-melt pressure-sensitive adhesive layer 2 is 0.36mm.

[0049] The raw materials of anti-sticking mineral particles are 99.62% of special white cement, 0.3% of polycarboxylate water reducer, 0.06% of defoamer, and 0.02% of retarder. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com