A method for preparing aluminum nitride powder based on aluminum carbide and its products

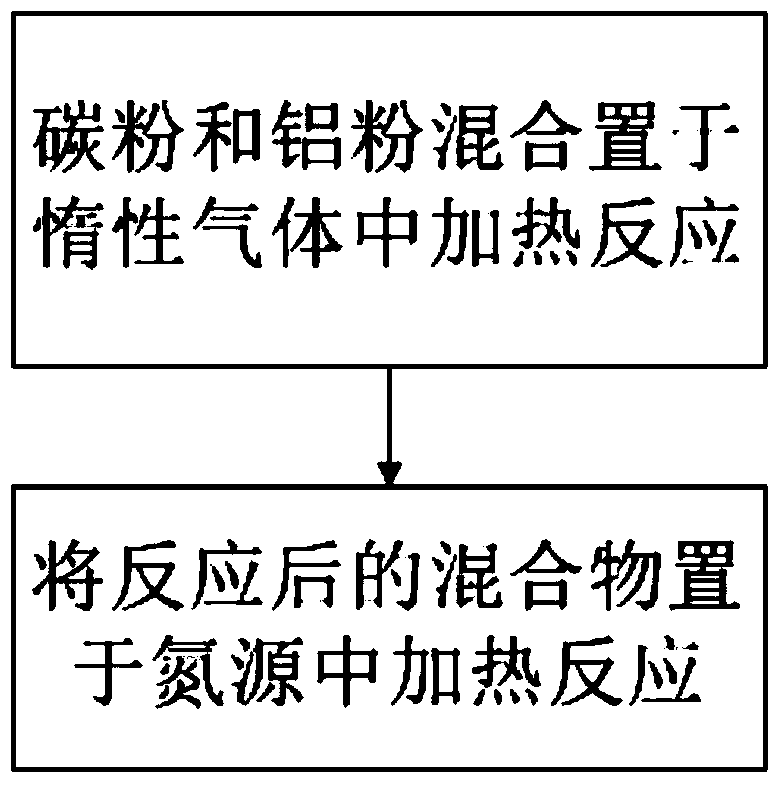

A technology of aluminum nitride and aluminum carbide, applied in the field of preparation of inorganic non-metallic powders, can solve the problems of low output, high reaction temperature, uneven particle size distribution, etc., achieve uniform particle size distribution, reduce reaction temperature, shorten the The effect of the generation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

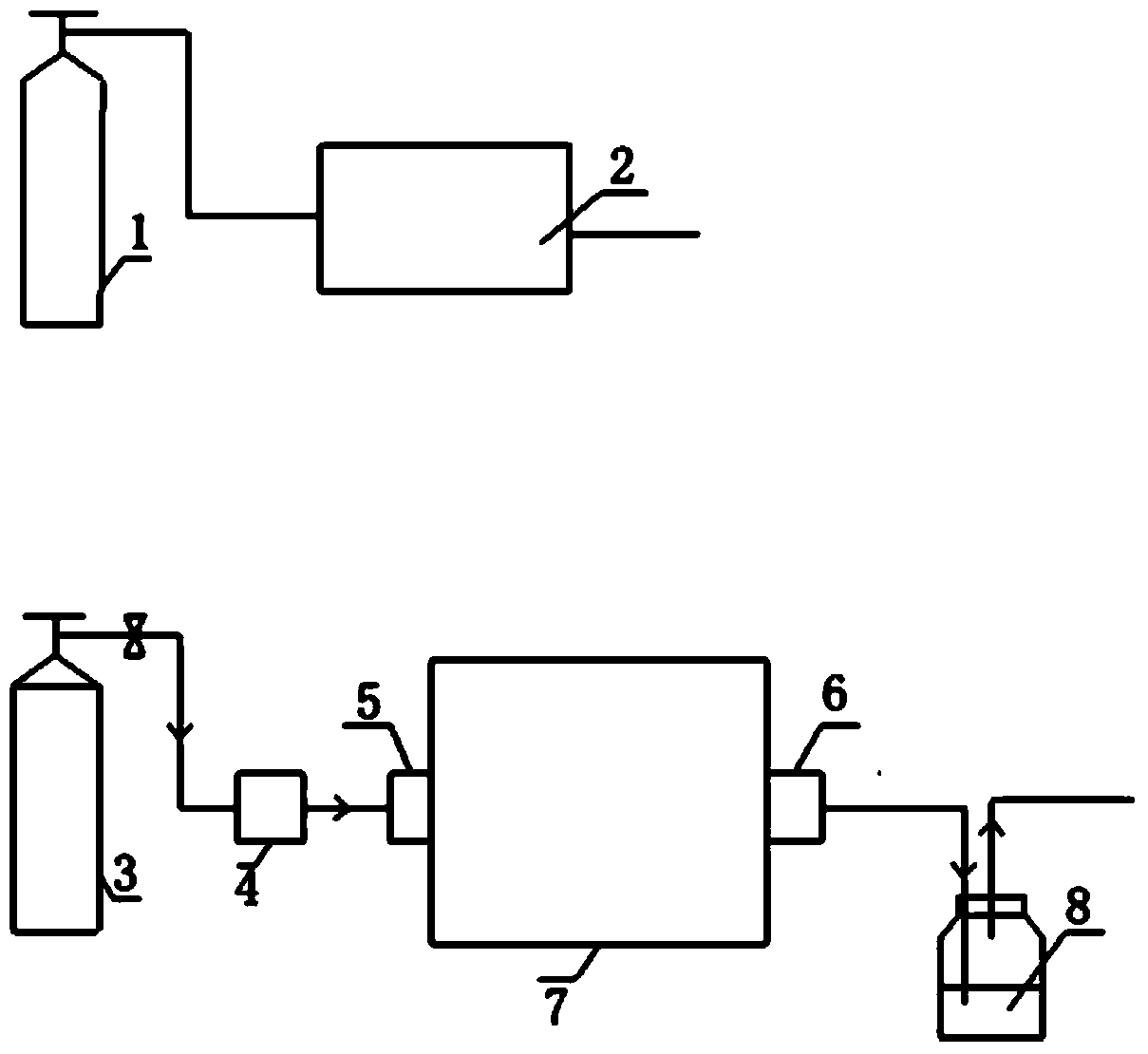

Embodiment 1

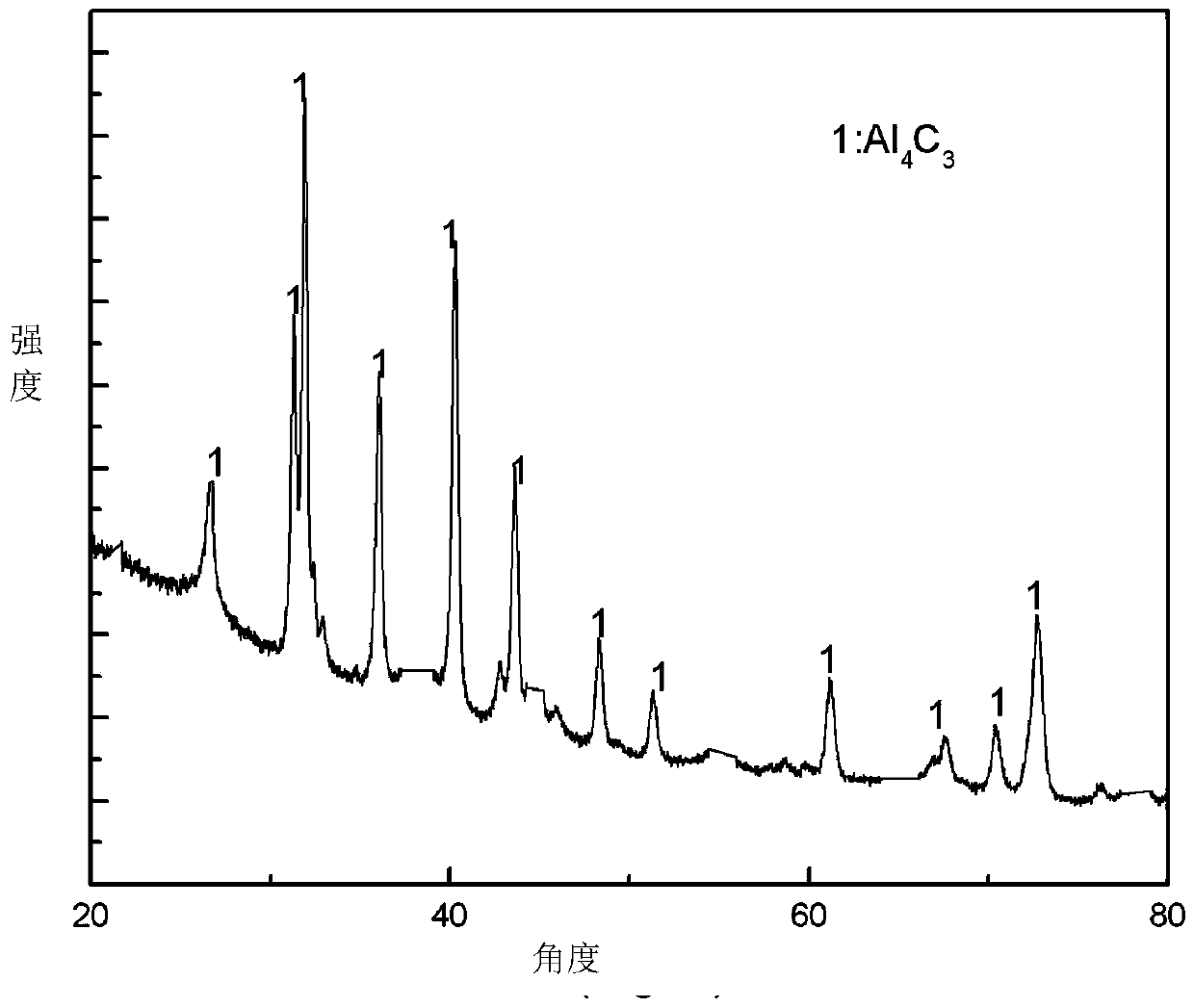

[0033] Mix 0.9g of micron aluminum powder and 0.3g of carbon powder evenly, the average particle size of the aluminum powder is 10 microns, the purity is 98.5%, the average particle size of the carbon powder is 20 microns, and the purity is 99.2%. In the box-type furnace, argon gas was introduced as a protective gas, and the flow rate of argon gas was 3L / h. The temperature of the box-type furnace was raised to 1000°C and kept for 3h. After the reaction is cooled to room temperature, evenly spread the generated aluminum carbide powder in the reaction vessel and place it in the tube furnace, feed ammonia gas, the flow rate of ammonia gas is 3L / h, raise the temperature of the tube furnace to 1200°C, and keep it warm for 6h. After the reaction is cooled to room temperature, a high-quality aluminum nitride powder product with high purity, fine particle size and low impurity oxygen content is produced.

Embodiment 2

[0035] Mix 0.9g of micron aluminum powder and 0.6g of carbon powder evenly. The average particle size of aluminum powder is 15 microns and the purity is 98%. The average particle size of carbon powder is 30 microns and the purity is 99%. In the box-type furnace, argon gas was introduced as a protective gas, and the flow rate of argon gas was 3L / h. The temperature of the box-type furnace was raised to 600°C and kept for 8h. After the reaction is cooled to room temperature, evenly spread the generated aluminum carbide powder in the reaction vessel and place it in the tube furnace, feed ammonia gas, the flow rate of ammonia gas is 3L / h, raise the temperature of the tube furnace to 1500°C, and keep it warm for 1h. After the reaction is cooled to room temperature, a high-quality aluminum nitride powder product with high purity, fine particle size and low impurity oxygen content is produced.

Embodiment 3

[0037] Mix 0.9g of micron aluminum powder and 0.4g of carbon powder evenly, the average particle size of aluminum powder is 12 microns, the purity is 98.4%, the average particle size of carbon powder is 25 microns, and the purity is 99.5%. In the box-type furnace, argon gas was introduced as a protective gas, and the flow rate of argon gas was 3L / h. The temperature of the box-type furnace was raised to 1300°C and kept for 1h. After the reaction is cooled to room temperature, evenly spread the generated aluminum carbide powder in a reaction vessel and place it in a tube furnace, and feed ammonia gas with a flow rate of 3L / h, raise the temperature of the tube furnace to 600°C, and keep it warm for 10 hours. After the reaction is cooled to room temperature, a high-quality aluminum nitride powder product with high purity, fine particle size and low impurity oxygen content is produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com