Matrix-carrier slow-release urea based on rare earth modification and strengthening and preparation method thereof

A slow-release urea and rare earth modification technology, applied in urea compound fertilizers, solid/semi-solid fertilizers, applications, etc., can solve the nutrient requirements of crops that are not suitable for long growth periods, are not suitable for sustainable development of modern agriculture, slow down It can improve the utilization rate of the season, enhance the photosynthesis ability, and improve the utilization rate and fertilizer efficiency period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] When preparing the rare earth-modified and strengthened matrix-carrier slow-release urea of the present invention, its preparation method includes the following steps.

[0034] (1) Add rare earth, pulverized lignin or at least one of straw or attapulgite or bentonite, and polyacrylamide into the urea melt. Wherein, lignin or straw or attapulgite or bentonite is pulverized and passed through a sieve of at least 100 meshes; the composition, polyacrylamide and rare earth can be added to the urea melt in sequence or after being mixed.

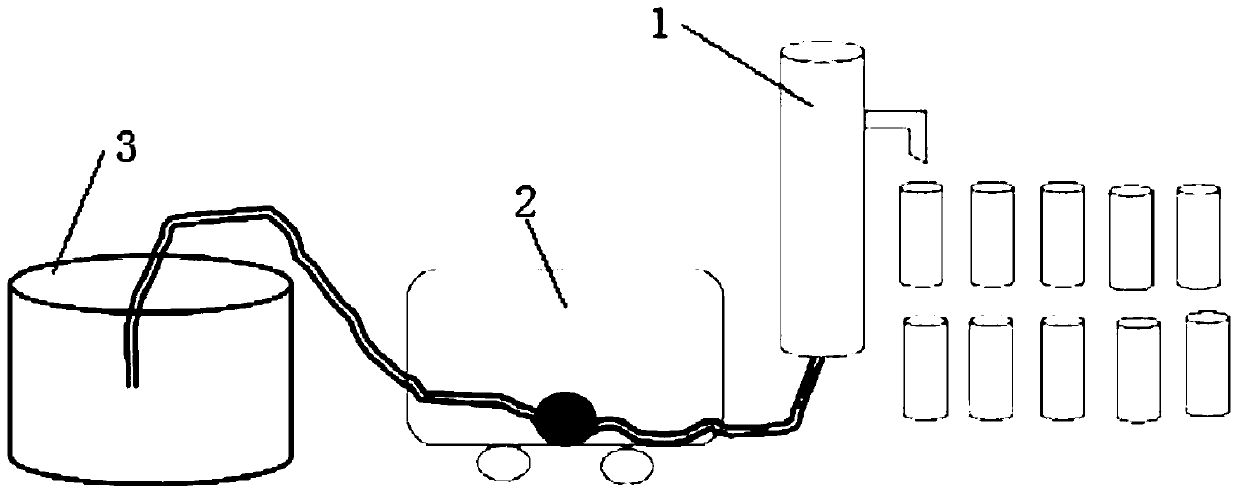

[0035] (2) Stir sufficiently, and prepare slow-release urea with different particle sizes from the mixed slurry. Wherein, the method for manufacturing slow-release urea with different particle sizes is selected from at least one of high tower, fluidized bed or drum.

[0036] The preparation method of the present invention has the advantages of low production cost and simple production process. It only needs to increase the weighing, trans...

Embodiment 1

[0038] The carrier-type slow-release urea based on rare earth modification and strengthening in this embodiment includes 95.8 parts of urea, 4 parts of bentonite, 0.1 part of polyacrylamide and 0.1 part of lanthanum nitrate.

[0039] The preparation method of this embodiment comprises the following steps:

[0040] (1) Add accurately weighed pulverized bentonite, polyacrylamide and lanthanum nitrate in the urea melting slurry pipeline, and mix the urea slurry after the pipeline mixer and urea melting by weight to obtain the mixed slurry;

[0041] (2) The mixed slurry enters the fluidized bed through the nozzle to complete the granulation process and produce large particles of slow-release urea.

Embodiment 2

[0043] A carrier-type slow-release urea based on rare earth modification and strengthening in this embodiment includes 95.4 parts of urea, 4 parts of straw, 0.1 part of polyacrylamide and 0.5 part of lanthanum acetate.

[0044] Other implementations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com