Preparation method of HPU plastic and construction process of HPU site

A technology of plastics and production methods, applied in the field of HPU plastic production and construction technology of HPU sites, can solve the problems of high production safety requirements, low rebound rate, long processing cycle, etc., and achieve curing speed and product quality. Effects, improved compression recovery and rebound rates, effects that are easy to add and manipulate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

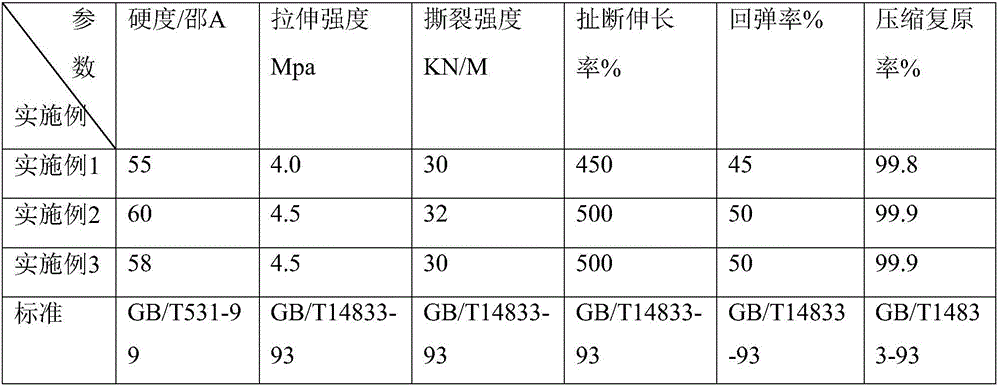

Embodiment 1

[0041] (1), the preparation of isocyanate component A: 60 parts of starters are the polyether polyol that the hydroxyl value that ethylene glycol and propylene oxide ring-opening polymerization obtains is 24, and molecular weight is 4675 is added in the reactor, at 85 Stir at ℃, vacuum dehydrate and degas, cool to 40℃, add 20 parts of diphenylmethane diisocyanate and 5 parts of isophordione diisocyanate, react at 70℃ for 2h, and cool to room temperature;

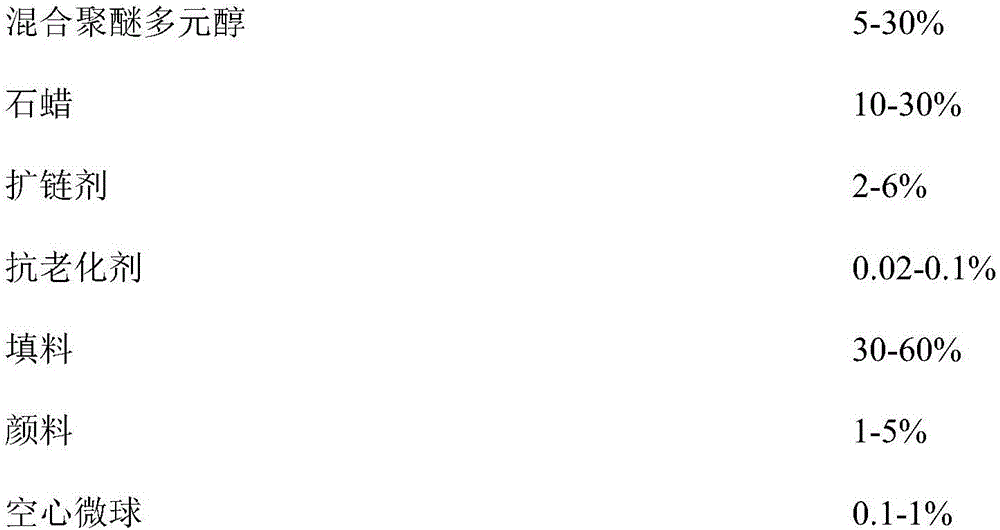

[0042](2), preparation of polyether component B: 5 parts of mixed polyether polyols (by accounting for 20% polyether polyol b1 of the total amount of mixed polyether polyols and accounting for 80% of total polyether polyols b2 composition, wherein, b1 is starting from glycerol, homopolyether polyol of propylene oxide, molecular weight 3500, functionality 3, hydroxyl value 48.1mgKOH / g, b2 is starting from dipropylene glycol, homopolyether polyol of propylene oxide Polyether polyol, molecular weight 4000, functionality 2, hydr...

Embodiment 2

[0045] (1) Preparation of isocyanate component A: Add 75 parts of polyether polyol with a hydroxyl value of 30 and a number average molecular weight of 5610 obtained by the ring-opening polymerization of glycerin and propylene oxide as an initiator into the reaction kettle, and heat Stir under vacuum, dehydrate and degas under vacuum, cool to 45°C, add 30 parts of diphenylmethane diisocyanate and 15 parts of isophordione diisocyanate, react at 80°C for 3 hours, and cool to room temperature;

[0046] (2), preparation of polyether component B: 30 parts of mixed polyether polyols (polyether polyol b1 accounting for 80% of the total amount of mixed polyether polyols and polyether polyols accounting for 20% of the total amount b2 composition, wherein, b1 is starting from glycerol, homopolyether polyol of propylene oxide, molecular weight 3500, functionality 3, hydroxyl value 48.1mgKOH / g, b2 is starting from dipropylene glycol, homopolyether polyol of propylene oxide Polyether polyo...

Embodiment 3

[0049] (1) Preparation of isocyanate component A: Add 68 parts of polyether polyols with a hydroxyl value of 40 and a number average molecular weight of 2800 obtained by ring-opening polymerization of 1,2-propylene glycol and propylene oxide as an initiator into the reactor , stirred at 100°C, vacuum dehydrated and degassed, cooled to 45°C, added 25 parts of diphenylmethane diisocyanate and 10 parts of isophordione diisocyanate, reacted at 70°C for 2 hours, and cooled to room temperature;

[0050] (2), preparation of polyether component B: 18 parts of mixed polyether polyols (by accounting for 60% polyether polyol b1 of the total amount of mixed polyether polyols and accounting for 40% polyether polyols of total amount) b2 composition, wherein, b1 is starting from glycerol, homopolyether polyol of propylene oxide, molecular weight 3000, functionality 3, hydroxyl value 56.1mgKOH / g, b2 is starting from dipropylene glycol, homopolyether polyol of propylene oxide Polyether polyol,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com