A processing method of composite insulator silicone rubber and the application of composite insulator silicone rubber in flame-retardant composite materials

A technology of flame-retardant composite materials and composite insulators, which is applied in the field of composite insulators, can solve problems such as inapplicability, and achieve the effects of improving flame-retardant effects, simple and feasible acidification treatment methods, and good synergistic flame-retardant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

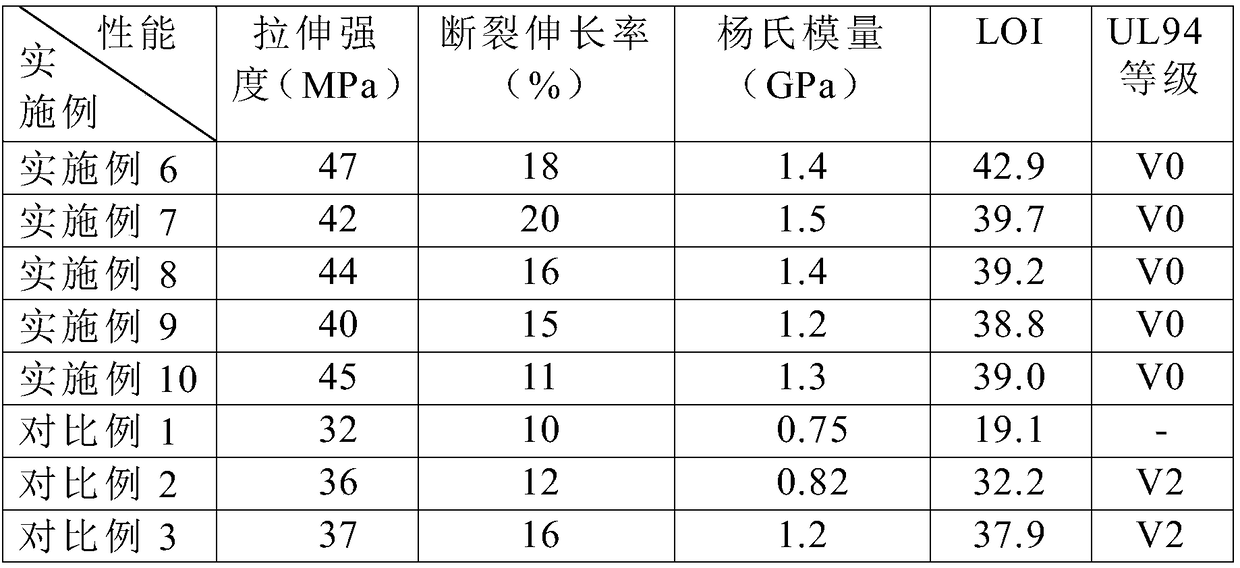

Examples

Embodiment 1

[0034] A processing method of composite insulator silicone rubber:

[0035] Recycling waste composite insulator silicone rubber materials, washing and crushing to obtain waste composite insulator silicone rubber powder;

[0036] Weigh 100g of waste composite insulator silicone rubber powder into a 1000ml three-necked bottle, and add 300g of concentrated hydrochloric acid, mechanically stir at 500 rpm for 4 hours, then add deionized water and continue stirring for 2 hours;

[0037] Filter the waste composite insulator silicone rubber powder after stirring and wash with deionized water until the filtrate is neutral, then soak in ethanol for 1h, filter and place in a hood until the ethanol is completely volatilized, and finally vacuum dry at 80℃ for 4h , Get composite insulator silicone rubber powder.

Embodiment 2

[0039] A processing method of composite insulator silicone rubber:

[0040] Recycling waste composite insulator silicone rubber materials, washing and crushing to obtain waste composite insulator silicone rubber powder;

[0041] Weigh 100g of waste composite insulator silicone rubber powder, and add 400g of concentrated hydrochloric acid to the waste composite insulator silicone rubber powder, mechanically stir at 400 rpm for 5 hours, then add deionized water and continue stirring for 1.5 hours;

[0042] Filter the waste composite insulator silicone rubber powder after mixing and wash with deionized water until the filtrate is neutral, then soak in methanol for 0.8h, filter and place in a hood until methanol is completely volatilized, and finally vacuum dry at 60℃ 3.5h, get composite insulator silicone rubber powder.

Embodiment 3

[0044] A processing method of composite insulator silicone rubber:

[0045] Recycling waste composite insulator silicone rubber materials, washing and crushing to obtain waste composite insulator silicone rubber powder;

[0046] Weigh 100g of waste composite insulator silicone rubber powder, and add 350g of concentrated hydrochloric acid to the waste composite insulator silicone rubber powder, mechanically stir at 520 rpm for 5 hours, then add deionized water and continue stirring for 1.2 hours;

[0047] Filter the waste composite insulator silicone rubber powder after mixing and wash with deionized water until the filtrate is neutral, then soak in tetrahydrofuran for 1.2h, filter and place in a ventilated kitchen until the tetrahydrofuran is completely volatilized, and finally vacuum dry at 65°C 4.5h, get composite insulator silicone rubber powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com